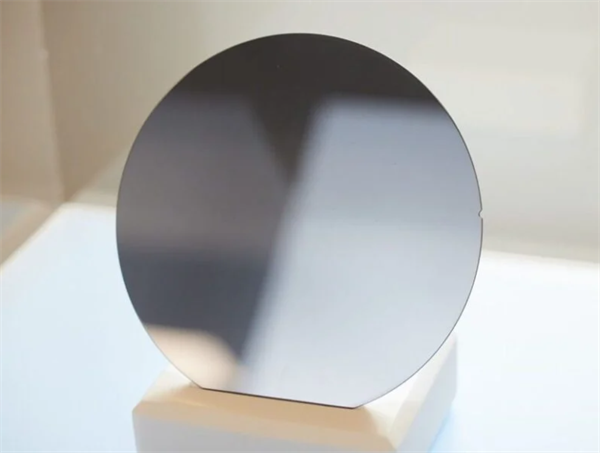

P-hom SiC wafer 4H / 6H-P 3C-N 6inch thickness 350 μm nrog Primary Flat Orientation

Specification4H / 6H-P Hom SiC Composite Substrates Cov lus sib piv

6 inch diameter Silicon Carbide (SiC) Substrate Specification

| Qib | Zero MPD ProductionQib (Z Qib) | Txuj ntau lawmQib (P Qib) | Dummy Qib (D Qib) | ||

| Txoj kab uas hla | 145.5mm ~ 150.0 hli | ||||

| Thickness | 350 μm ± 25 μm | ||||

| Wafer Orientation | -Offaxis: 2.0 ° -4.0 ° rau [1120] ± 0.5 ° rau 4H / 6H-P, On axis: 〈111〉 ± 0.5 ° rau 3C-N | ||||

| Micropipe ntom ntom | 0 cm-2 | ||||

| Kev tiv thaiv | p-type 4H/6H-P | ≤0.1 Ωꞏcm | ≤0.3 Ωꞏcm | ||

| N-type 3C-N | ≤ 0.8 mΩ ꞏcm | ≤1m Ωꞏcm | |||

| Thawj Txoj Kev Ncaj Ncees | 4H/6H-P | -{1010} ± 5.0° | |||

| 3 C-N | -{110} ± 5.0° | ||||

| Qhov Loj Loj Loj | 32.5 hli ± 2.0 hli | ||||

| Secondary Flat Length | 18.0 hli ± 2.0 hli | ||||

| Secondary Flat Orientation | Silicon lub ntsej muag: 90 ° CW. los ntawm Prime tiaj tus ± 5.0 ° | ||||

| Ntug Exclusion | 3 hli | 6 hli | |||

| LTV/TTV/How/Warp | ≤ 2.5 μm / ≤5 μm / ≤ 15 μm / ≤ 30 μm | ≤ 10 μm / ≤ 15 μm / ≤ 25 μm / ≤ 40 μm | |||

| Roughness | Polish Ra≤1nm | ||||

| CMP Ra≤0.2nm | Ra≤0.5nm | ||||

| Ntug Cracks Los ntawm High Intensity Light | Tsis muaj | Qhov ntev ≤ 10 hli, ib qhov ntev ≤ 2 hli | |||

| Hex Phaj Los Ntawm Lub Teeb Siab Siab | Thaj tsam ≤ 0.05% | Qhov loj me ≤0.1% | |||

| Polytype Areas Los Ntawm Lub Teeb Siab Siab | Tsis muaj | Thaj tsam ≤ 3% | |||

| Visual Carbon suav nrog | Thaj tsam ≤ 0.05% | Qhov loj me ≤ 3% | |||

| Silicon Surface Scratches Los ntawm High Intensity Light | Tsis muaj | Qhov ntev ≤1 × wafer txoj kab uas hla | |||

| Ntug Chips Siab Los Ntawm Kev Siv Lub Teeb | Tsis muaj kev tso cai ≥0.2mm dav thiab qhov tob | 5 tso cai, ≤1mm txhua | |||

| Silicon Surface Contamination Los Ntawm Kev Siv Siab | Tsis muaj | ||||

| Ntim | Multi-wafer Cassette lossis Ib Lub Thawv Wafer | ||||

Nco tseg:

※ Cov kev txwv tsis raug siv rau tag nrho wafer nto tsuas yog rau thaj tsam ntawm ntug kev cais tawm. # Cov khawb yuav tsum tau kuaj xyuas ntawm Si ntsej muag o

P-hom SiC wafer, 4H / 6H-P 3C-N, nrog nws qhov loj 6-nti thiab 350 μm tuab, ua lub luag haujlwm tseem ceeb hauv kev tsim khoom ntawm cov khoom siv hluav taws xob ua haujlwm siab. Nws zoo heev thermal conductivity thiab siab tawg voltage ua rau nws zoo tagnrho rau kev tsim khoom xws li fais fab hloov, diodes, thiab transistors siv nyob rau hauv high-kub ib puag ncig xws li hluav taws xob tsheb, hluav taws xob daim phiaj, thiab lub zog tauj dua tshiab. Lub wafer lub peev xwm los ua haujlwm tau zoo hauv cov xwm txheej hnyav ua kom ntseeg tau tias kev ua haujlwm zoo hauv kev lag luam siv yuav tsum muaj lub zog ceev thiab lub zog ua haujlwm. Tsis tas li ntawd, nws cov kev taw qhia ncaj nraim hauv kev sib raug zoo meej thaum lub sij hawm tsim khoom, txhim kho kev tsim khoom thiab cov khoom sib xws.

Qhov zoo ntawm N-hom SiC composite substrates suav nrog

- High Thermal conductivity: P-hom SiC wafers zoo dissipate cua sov, ua rau lawv zoo tagnrho rau cov ntawv thov kub.

- High Breakdown Voltage: Muaj peev xwm tiv taus cov hluav taws xob siab, ua kom muaj kev ntseeg siab hauv cov hluav taws xob hluav taws xob thiab cov khoom siv hluav taws xob siab.

- Kev Ua Phem Rau Ib puag ncig hnyav: Zoo heev durability nyob rau hauv huab mob, xws li kub kub thiab corrosive ib puag ncig.

- Fais fab hloov dua siab tshiab: P-hom doping ua kom yooj yim zog tuav, ua rau lub wafer haum rau lub zog hloov dua siab tshiab.

- Thawj Txoj Kev Ncaj Ncees: Ua kom muaj kev sib raug zoo hauv kev tsim khoom, txhim kho cov khoom raug thiab sib xws.

- Nyias Structure (350 μm): Lub wafer qhov pom zoo thickness txhawb kev koom ua ke rau hauv cov khoom siv hluav taws xob siab heev, qhov chaw txwv tsis pub siv.

Zuag qhia tag nrho, P-hom SiC wafer, 4H / 6H-P 3C-N, muaj ntau yam zoo uas ua rau nws tsim nyog rau kev lag luam thiab kev siv hluav taws xob. Nws cov thermal conductivity thiab tawg voltage pab txhim khu kev qha ua haujlwm nyob rau hauv high-temperature thiab high-voltage ib puag ncig, thaum nws tsis kam mus rau hnyav tej yam kev mob kom durability. P-hom doping tso cai rau kev hloov hluav taws xob zoo, ua rau nws zoo tagnrho rau lub zog hluav taws xob thiab lub zog hluav taws xob. Tsis tas li ntawd, lub wafer lub hauv paus tiaj tus taw qhia kom meej meej thaum lub sijhawm tsim khoom, txhim kho cov khoom sib xws. Nrog lub thickness ntawm 350 μm, nws yog zoo-tsim rau kev koom ua ke rau hauv siab, compact li.

Daim duab qhia ntxaws