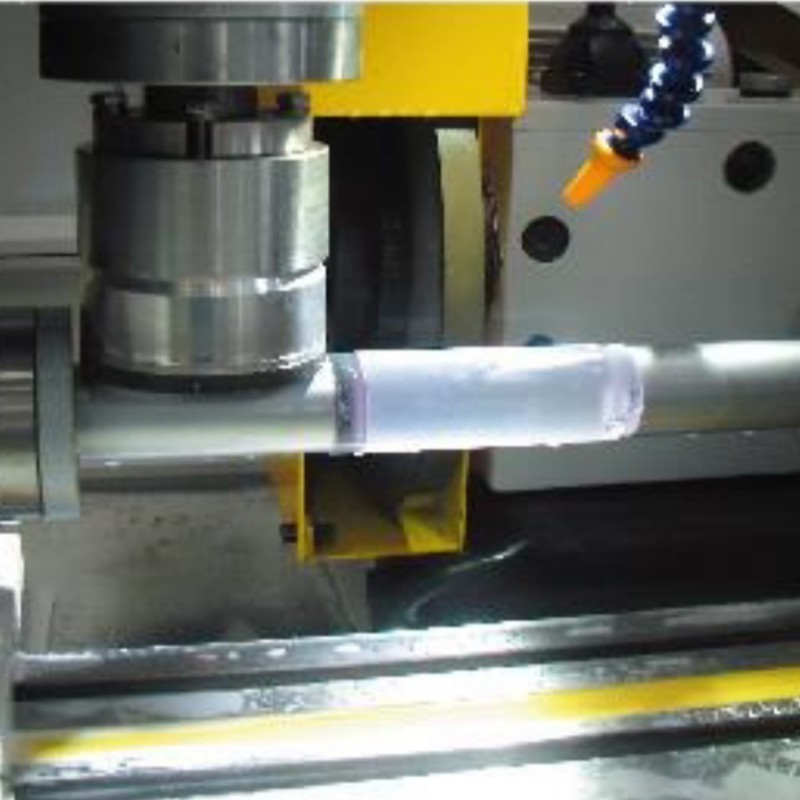

Precision Microjet Laser System rau Hard & Brittle Materials

Cov yam ntxwv tseem ceeb

Rigid Cross-Slide Structure

Tus ntoo khaub lig-slide hom puag nrog symmetric thickened qauv minimizes thermal deformation thiab xyuas kom meej lub sij hawm ntev. Qhov kev teeb tsa no muab qhov zoo tshaj plaws rigidity thiab tso cai rau kev sib tsoo ruaj khov hauv kev ua haujlwm tsis tu ncua.

Independent Hydraulic System rau Reciprocating Motion

Lub rooj sab laug-txoj cai reciprocating zog yog powered los ntawm ib tug ywj siab hydraulic chaw nres tsheb nrog ib tug electromagnetic valve reversing system. Qhov no ua rau muaj kev sib tw, tsis tshua muaj suab nrov nrog kev tsim hluav taws xob tsawg, ua rau nws tsim nyog rau kev tsim khoom mus sij hawm ntev.

Anti-Mist Honeycomb Baffle Design

Nyob rau sab laug ntawm lub rooj ua haujlwm, cov ntaub thaiv npog honeycomb-style dej zoo txo cov huab cua tsim los ntawm kev sib tsoo ntub dej, txhim kho kev pom thiab kev huv hauv lub tshuab.

Dual V-Guide Rails nrog Servo Pob Ntsia Hlau Pub

Lub rooj sib tham pem hauv ntej thiab nram qab siv qhov ntev-ntev dual V-shaped qhia rails nrog lub servo lub cev muaj zog thiab pob ntsia hlau tsav. Qhov kev teeb tsa no ua rau kev pub mis tsis siv neeg, qhov chaw raug siab, thiab cov khoom siv txuas ntxiv mus.

Vertical Feed nrog High Rigidity Guide

Txoj kev txav ntsug ntawm lub taub hau sib tsoo siv cov square steel guideways thiab servo-tsav pob screws. Qhov no ua kom muaj kev ruaj ntseg siab, rigidity, thiab tsawg heev backlash, txawm tias thaum sib sib zog nqus txiav los yog tiav lawm.

High-Precision Spindle Assembly

Nruab nrog lub siab-rigidity thiab high-precision bearing spindle, lub taub hau sib tsoo muab superior txiav efficiency. Qhov kev ua tau zoo sib xws ua kom muaj qhov zoo tshaj plaws ntawm qhov kawg thiab ua kom lub neej ntev ntawm spindle.

Advanced Electrical System

Siv Mitsubishi PLCs, servo motors, thiab servo drives, hluav taws xob tswj system yog tsim los rau kev ntseeg tau thiab yoog raws. Ib qho khoom siv hluav taws xob sab nraud muaj kev tswj xyuas zoo thiab ua kom yooj yim cov txheej txheem teeb tsa.

Sealed thiab Ergonomic Tsim

Tus qauv tsim tag nrho tsis tsuas yog txhim kho kev nyab xeeb ntawm kev ua haujlwm tab sis kuj tseem ua kom qhov chaw sab hauv huv si. Aesthetic sab nrauv casing nrog optimized qhov ntev ua rau lub tshuab yooj yim los tswj thiab hloov chaw.

Cov cheeb tsam thov

Sapphire Wafer Sib Tsoo

Qhov tseem ceeb rau LED thiab semiconductor industries, lub tshuab no ua kom lub tiaj tiaj thiab ntug kev ncaj ncees ntawm sapphire substrates, uas yog qhov tseem ceeb rau kev loj hlob ntawm epitaxial thiab lithography.

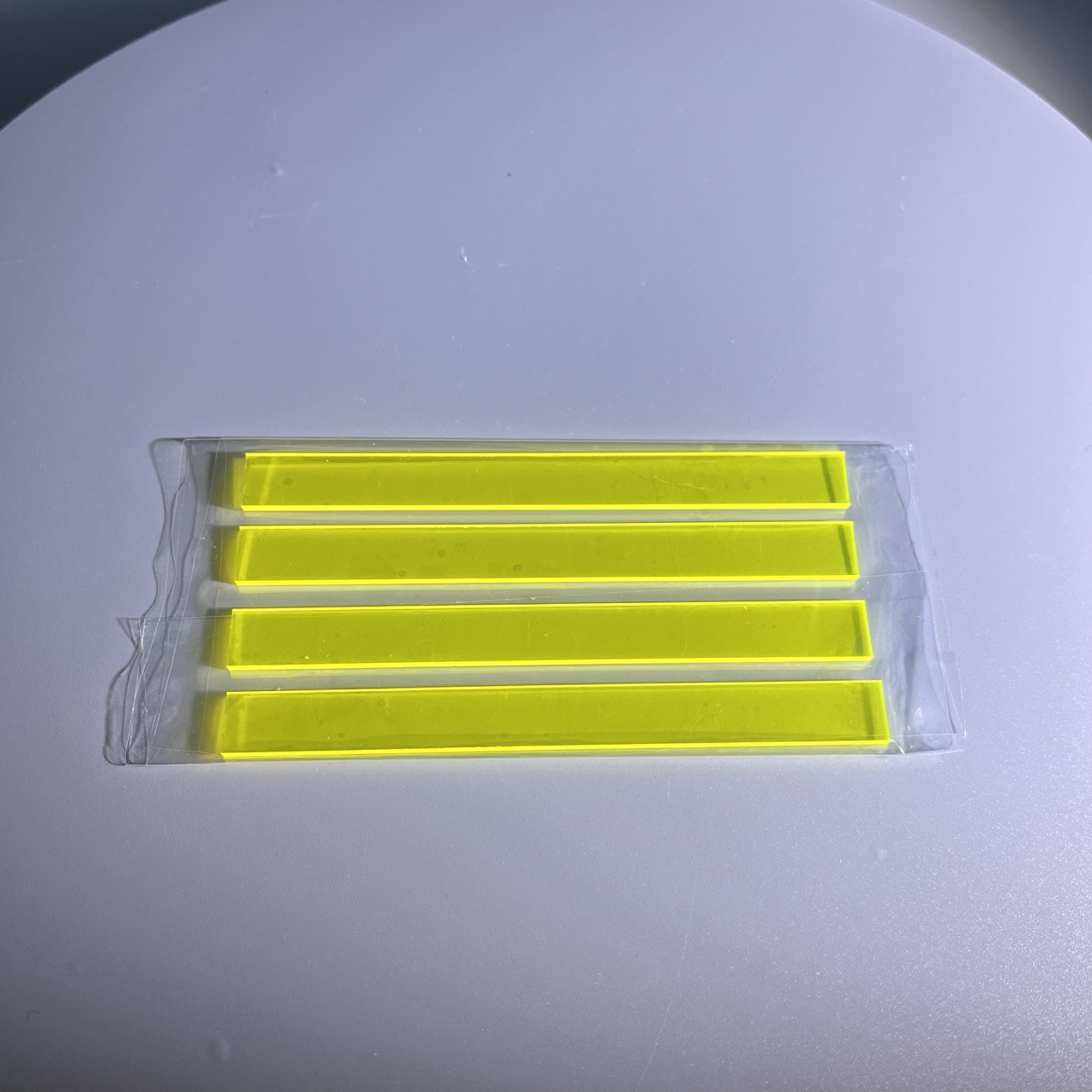

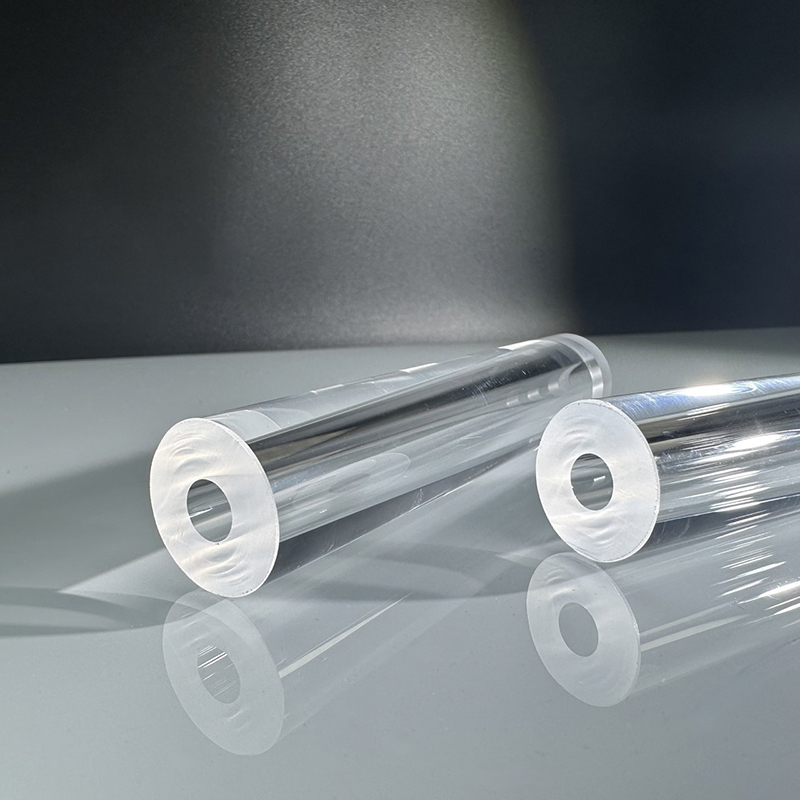

Optical iav thiab qhov rai substrates

Qhov zoo tshaj plaws rau kev ua cov qhov rais laser, cov iav ua haujlwm siab, thiab lub koob yees duab tiv thaiv lub ntsej muag, xa cov lus pom tseeb thiab kev ncaj ncees.

Ceramic thiab Advanced Materials

Muaj feem xyuam rau alumina, silicon nitride, thiab aluminium nitride substrates. Lub tshuab tuaj yeem tuav cov ntaub ntawv me me thaum tswj kev ua siab ntev.

Kev tshawb fawb thiab kev loj hlob

Nyiam los ntawm cov koom haum tshawb fawb rau kev sim cov khoom npaj vim nws txoj kev tswj hwm thiab kev ua tau zoo.

Qhov zoo piv rau cov tsoos sib tsoo tshuab

● Superior raug nrog servo-driven axes thiab nruj kev tsim kho

● Cov ntaub ntawv tshem tawm sai dua yam tsis muaj kev cuam tshuam rau saum npoo

● Tsawg suab nrov thiab thermal hneev taw ua tsaug rau hydraulic thiab servo systems

● Kev pom tau zoo dua thiab ua haujlwm huv dua vim muaj kev tiv thaiv pos huab

● Txhim kho cov neeg siv interface thiab cov txheej txheem kho kom yooj yim dua

Kev tu thiab kev txhawb nqa

Kev saib xyuas niaj hnub yog yooj yim nrog cov txheej txheem nkag tau yooj yim thiab cov neeg siv kev tswj hwm zoo. Lub tshuab spindle thiab cov lus qhia yog tsim los rau kev ua haujlwm ntev, yuav tsum tau muaj kev cuam tshuam tsawg. Peb pab pawg pab txhawb nqa muaj kev cob qhia, cov khoom seem, thiab kev kuaj mob hauv online kom ntseeg tau tias kev ua haujlwm siab tshaj plaws thoob plaws lub tshuab lub neej.

Specification

| Qauv | qw 015 | qw 018 |

| Max Workpiece Loj | 12 nti | 8 nti |

| Max Workpiece Length | 275 hli | 250 hli |

| Rooj ceev | 3-25m / min | 5-25m / min |

| Sib tsoo Log Loj | φ350xφ127mm (20-40mm) | φ205xφ31.75mm (6-20mm) |

| Spindle Ceev | 1440rpm ua | 2850rpm ua |

| Flatness | ± 0.01 hli | ± 0.01 hli |

| Parallelism | ± 0.01 hli | ± 0.01 hli |

| Tag Nrho Lub Zog | 9 kW ua | 3 kW |

| Tshuab hnyav | 3,5t :ua | 1,5t ib |

| Qhov ntev (L x W x H) | 2450 x 1750 x 2150 mm | 2080 x 1400 x 1775 mm |

Xaus

Txawm hais tias kev tsim khoom loj lossis kev tshawb fawb, Sapphire CNC Surface Sib Tsoo Tshuab muab qhov tseeb thiab kev ntseeg siab uas yuav tsum tau ua rau cov khoom siv niaj hnub no. Nws cov qauv tsim ntse thiab cov khoom siv ruaj khov ua rau nws muaj peev xwm mus sij hawm ntev rau txhua qhov kev tsim khoom siv high-tech.

Daim duab qhia ntxaws