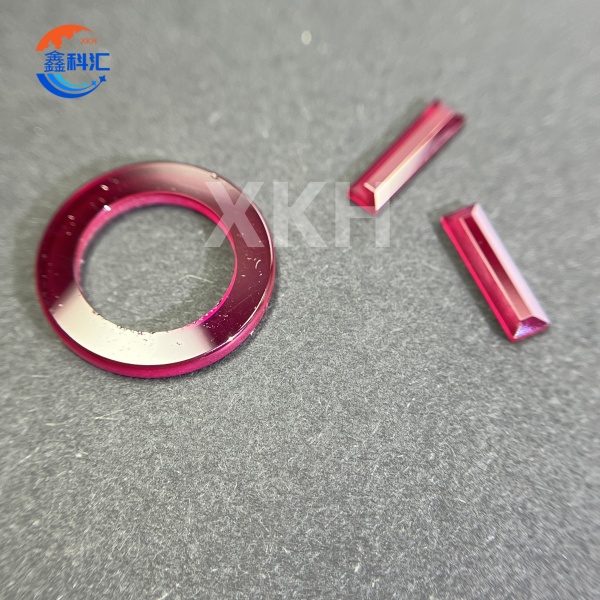

Ruby Optical Cheebtsam Precision Windows Bearing Assemblies High-Temperature Resistance

Sapphire (α-Al₂O₃) tau tshwm sim los ua cov khoom siv tseem ceeb hauv kev lag luam niaj hnub no, ua kom pom tus nqi hloov tsis tau thoob plaws ntau daim ntawv thov high-tech vim nws cov khoom tshwj xeeb physicochemical. Raws li ib tug thawj coj ntawm sapphire cov ntaub ntawv daws teeb meem, XKH muaj tag nrho cov kev lag luam saw muaj peev xwm - los ntawm siv lead ua kev loj hlob mus rau precision machining - ua rau peb xa customized sapphire Cheebtsam xws li kho qhov muag qhov rais, mechanical bearings, thiab laser ntsiab. Leveraging advanced manufacturing technologies thiab nruj zoo tswj systems, peb tau cog lus los muab kev lag luam cov neeg siv nrog high-kev ua tau zoo, txhim khu kev qha sapphire khoom daws teeb meem.

Technical specification:

| Qeb Parameter | Specification |

| Cov cuab yeej yooj yim | |

| Crystal Structure | Hexagonal (α-Al₂O₃) |

| Mohs Hardness | 9 |

| Qhov ntom | 3.98 g / cm³ |

| Melting Point | 2050 ° C |

| Optical Properties | |

| Kev sib kis | 0.15-5.5 hli |

| Refractive Index | 1.76nm589 ua |

| Birefringence | 0.008 ib |

| Mechanical Properties | |

| Flexural zog | 400-700 MPa |

| Elastic Modulus | 345 gpa ua |

| Thermal Expansion Coeff. | 7.5 × 10⁻⁶ / K (25-1000 ° C) |

| Kev kho saum npoo | |

| Txheem tiav | Ra ≤ 0.05 μm |

| High Precision tiav | Ra ≤ 0.01 μm |

| Txheej txheej xaiv | AR / HR / Hlau txheej |

Cov yam ntxwv tseem ceeb:

- Exceptional Environmental Adaptability

Sapphire Cheebtsam muaj kev ua tau zoo nyob rau hauv ib puag ncig huab, tswj kev ua haujlwm ruaj khov thoob plaws qhov kub thiab txias ntawm -200 ° C txog + 1000 ° C. Lawv cov qauv siv lead ua tshwj xeeb imparts superior thermal poob siab tsis kam, tiv thaiv kev tawg lossis deformation txawm nyob rau hauv qhov kub hloov pauv sai. Nyob rau hauv lub tshuab nqus tsev, sapphire Cheebtsam muaj kev ntseeg siab ntawm ultra-high nqus (10⁻⁶ Pa) yam tsis muaj paug paug. Tsis tas li ntawd, sapphire qhia tau hais tias muaj kev tiv thaiv hluav taws xob zoo heev, ua kom muaj kev ncaj ncees thiab kev ua haujlwm ntawm cov hluav taws xob ntau txog 10⁶ Gy.

- Unparalleled Durability

Nrog rau Mohs hardness ntawm 9 (thib ob xwb rau pob zeb diamond), sapphire Cheebtsam muab tshwj xeeb hnav tsis kam. Kev ntsuas sib piv qhia tau hais tias sapphire qhov chaw pom tus nqi hnav tsuas yog 1/10th ntawm cov khoom siv hlau. Chemically, sapphire tiv taus yuav luag txhua cov kua qaub uas muaj zog (tsis suav HF), alkalis, thiab cov kuab tshuaj organic. Cov khoom no ua rau cov khoom siv sapphire kom ua tiav cov kev pab cuam lub neej 5-8 zaug ntev dua li cov khoom siv ib txwm, txo cov nqi kho thiab txo sijhawm.

- Superior Precision kev ua tau zoo

Sapphire components provide unique advantages in precision manufacturing. Their ultra-low thermal expansion coefficient (7.5×10⁻⁶/K) ensures dimensional stability, typically achieving ±0.1μm/100mm variation. Through precision machining, we achieve surface flatness of λ/10@632.8nm and angular tolerances of ±15 arc-seconds, meeting the most stringent optical system requirements. These characteristics make sapphire ideal for high-precision measurement and optical applications.

Qhov Zoo Tshaj Plaws:

- Performance-to-Cost Ratio

Peb cov khoom siv sapphire tuav ntau dua 85% ntawm cov ntsuas kev ua haujlwm tseem ceeb thaum muab ntau dua 30% kev txuag nqi piv rau cov khoom siv sapphire ib txwm muaj. Los ntawm optimized siv lead ua kev loj hlob thiab machining txheej txheem, peb ua tiav qhov zoo sib npaug ntawm kev ua tau zoo thiab tus nqi. Kev tswj xyuas nruj kom ntseeg tau tias batch-rau-batch sib xws nrog ≤3% parameter sib txawv.

- Kev Pabcuam Muaj Peev Xwm

Peb tuav cov lus teb ceev ceev, xa cov kev daws teeb meem hauv 48 teev. Peb cov qauv tsim tau yooj yim haum rau kev txiav txim los ntawm 1 txog 10,000 units. Cov txheej txheem tshuaj xyuas 36-kauj ruam suav nrog qhov tseeb qhov tseeb, qhov zoo ntawm qhov chaw, thiab cov khoom siv kho tshuab kom lav cov qauv zoo.

Cov ntawv thov tseem ceeb:

High-End Industrial Applications

Semiconductor Manufacturing: Qhia rails rau wafer tuav robots

Precision Metrology: Kev soj ntsuam rau CMMs (Kev Sib Koom Tes Ntsuas Tshuab)

Fiber Optics: Kos lub nozzles nrog superior thermal stability

2. Advanced Optical Systems

Laser Technology: High-LIDT (Laser-Induced Damage Threshold) qhov rais thiab Q-switches

Kev siv tiv thaiv: Infrared missile domes

Spectroscopy: Prisms thiab qhov rais rau kev ntsuas ntsuas

3. Kev siv ib puag ncig huab cua

Aerospace: Cwj pwm tswj bearings rau spacecraft

Kev Tshawb Fawb Hauv Dej Hiav Txwv: Siab-resistant viewports

Kev Lag Luam Nuclear: Cov Hluav Taws Xob-shielded saib qhov rais

XKH'sKev pabcuam:

XKH muab qhov kawg-rau-kawg sapphire tivthaiv kev daws teeb meem:

· Cov Khoom Muag Khoom: 200+ tus qauv qauv hauv Tshuag; kev cai loj ntawm 0.5-300mm

· Kev Pabcuam: Daim ntawv thov engineering, FEA simulation, tsis ua hauj lwm tsom xam

· Kev Kho Hniav: DLC txheej, AR (Anti-Reflective) txheej

· Quality Assurance: Cov ntaub ntawv pov thawj ntawm kev soj ntsuam thib peb

· Logistics: 48-teev technical proposals; 2-4 lub lis piam coj mus kuaj

Xaus

Sapphire Cheebtsam xa cov nqi tshwj xeeb hauv high-end industrial applications los ntawm lawv cov khoom tsis sib haum xeeb ntawm lub cev. Daim ntawv tshaj tawm no tau piav qhia txog lawv cov yam ntxwv tseem ceeb, qhov zoo, thiab kev siv ntau yam. Los ntawm kev sib txuas cov kev pabcuam muaj zog nrog kev tswj xyuas zoo, XKH muab cov kev daws teeb meem zoo tshaj plaws, tus nqi zoo sapphire. Tsiv mus tom ntej, peb yuav txuas ntxiv ua kom cov khoom ua tau zoo thiab cov thev naus laus zis los nthuav dav sapphire cov ntawv thov hauv semiconductors, optics, aerospace, thiab tshaj. Peb zoo siab tos txais kev koom tes nrog cov koom tes hauv kev lag luam los koom ua ke tsav kev tsim kho tshiab hauv sapphire khoom siv tshuab.