Sapphire Crystal Growth Rauv KY Kyropoulos Txoj Kev rau Sapphire Wafer thiab Optical Window Production

Txoj Cai Ua Haujlwm

Lub hauv paus ntsiab lus tseem ceeb ntawm KY txoj kev suav nrog melting high-purity Al₂O₃ raw cov ntaub ntawv nyob rau hauv ib tug tungsten / molybdenum crucible ntawm 2050 ° C. Cov noob siv lead ua tau qis dua rau hauv cov yaj, ua raws li kev tswj hwm kev tshem tawm (0.5-10 mm / h) thiab kev sib hloov (0.5-20 rpm) kom ua tiav kev loj hlob ntawm α-Al₂O₃ ib leeg muaju. Cov yam ntxwv tseem ceeb muaj xws li:

• Loj-dimension muaju (max. Φ400 mm × 500 mm)

• Tsawg-stress optical-qib sapphire (wavefront distortion <λ/8 @ 633 nm)

• Doped crystals (piv txwv li, Ti³⁰ doping rau lub hnub qub sapphire)

Core System Cheebtsam

1. Kub-kub Melting System

• Tungsten-molybdenum composite crucible (max. temp. 2300 ° C)

• Multi-zone graphite rhaub (± 0.5 ° C kub tswj)

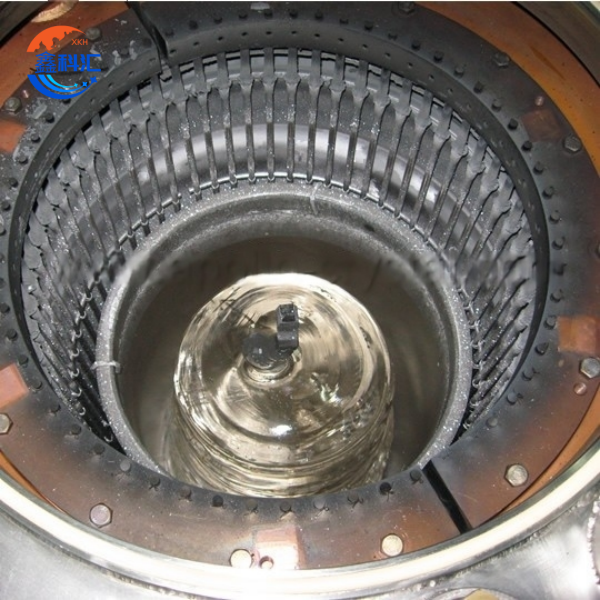

2. Crystal Growth System

• Servo-tsav rub mechanism (± 0.01 hli precision)

• Sib nqus kua rotary foob (0–30 rpm stepless ceev tswj)

3. Thermal Field Control

• 5-zone ywj siab tswj qhov kub thiab txias (1800-2200 ° C)

• Kho tau tshav kub tiv thaiv (± 2 ° C / cm gradient)

• Vacuum & Atmosphere System

• 10⁻⁴ Pa lub tshuab nqus tsev siab

• Ar/N₂/H₂ sib xyaw roj tswj

4. Kev soj ntsuam ntse

• CCD lub sij hawm tiag tiag siv lead ua txoj kab uas hla xyuas

• Multi-spectral melt level detection

KY vs. CZ Method Comparison

| Qhov Parameter | KY Method | CZ Method |

| Max. Crystal Loj | Φ400 hli | Φ200 hli |

| Kev Loj Hlob | 5-15 hli / h | 20-50mm / h |

| Defect Density | <100/cm² | 500-1000 / cm² |

| Kev siv hluav taws xob | 80-120 kWh/kg | 50-80 kWh/kg |

| Tej kev siv | Optical windows / loj wafers | LED substrates / hniav nyiaj hniav kub |

Cov ntawv thov tseem ceeb

1. Optoelectronic Windows

• Tub rog IR domes (kev xa tawm> 85% @ 3-5 μm)

• UV laser qhov rais (nrog 200 W / cm² zog ceev)

2. Semiconductor Substrates

• GaN epitaxial wafers (2–8 nti, TTV <10 μm)

• SOI substrates (nto roughness <0.2 nm)

3. Consumer Electronics

• Smartphone lub koob yees duab npog iav (Mohs hardness 9)

• Smartwatch qhia (10 × khawb tiv thaiv kev txhim kho)

4. Cov khoom siv tshwj xeeb

• High-purity IR optics (absorption coefficient <10⁻³ cm⁻¹)

• Nuclear reactor soj ntsuam windows (radiation kam rau ua: 10¹⁶ n / cm²)

Qhov zoo ntawm Kyropoulos (KY) Sapphire Crystal Growth Equipment

Lub Kyropoulos (KY) txoj kev-raws li sapphire siv lead ua kev loj hlob cov cuab yeej muaj qhov zoo sib xws, muab nws ua cov kev daws teeb meem rau kev tsim khoom lag luam. Cov txiaj ntsig tseem ceeb suav nrog:

1. Loj-Diameter Capability : Muaj peev xwm loj hlob sapphire siv lead ua mus txog 12 ntiv tes (300 mm) hauv txoj kab uas hla, ua kom muaj txiaj ntsig zoo ntawm cov wafers thiab cov khoom siv kho qhov muag rau kev siv qib siab xws li GaN epitaxy thiab cov tub rog-qib qhov rais.

2. Ultra-Low Defect Density : Ua tiav qhov sib txawv ntawm qhov ntom ntom <100 / cm² los ntawm kev ua kom zoo thermal teb tsim thiab meej kub gradient tswj, kom ntseeg tau zoo siv lead ua kev ncaj ncees rau optoelectronic li.

3. High-Quality Optical Performance : Muab kev xa tawm> 85% ntawm pom rau infrared spectra (400–5500 nm), tseem ceeb rau UV laser qhov rais thiab infrared optics.

4. Advanced Automation : Nta servo-driven rub mechanisms (± 0.01 mm precision) thiab sib nqus kua rotary seals (0-30 rpm stepless tswj), txo tib neeg kev cuam tshuam thiab txhim kho kev sib xws.

5. Cov kev xaiv yooj yim Doping : Txhawb kev hloov kho nrog dopants xws li Cr³⁰ (rau ruby) thiab Ti³⁰ (rau lub hnub qub sapphire), ua rau kev lag luam niche hauv optoelectronics thiab hniav nyiaj hniav kub.

6. Zog Efficiency : Optimized thermal rwb thaiv tsev (tungsten-molybdenum crucible) txo lub zog noj mus rau 80-120 kWh / kg, sib tw nrog lwm txoj kev loj hlob.

7. Scalable Production : Ua tiav cov zis txhua hli ntawm 5,000+ wafers nrog lub sij hawm voj voog ceev (8-10 hnub rau 30-40 kg crystals), validated los ntawm ntau tshaj 200 thoob ntiaj teb kev teeb tsa.

ua

8. Tub Rog-Qib Durability : Sib txuas cov qauv hluav taws xob tiv thaiv hluav taws xob thiab cov khoom siv hluav taws xob (tiv taus 10¹⁶ n / cm²), qhov tseem ceeb rau kev siv aerospace thiab nuclear.

Cov kev tsim kho tshiab no ua rau KY txoj hauv kev ua tus qauv kub rau kev tsim cov sapphire siv lead ua muaj zog, tsav kev nce qib hauv 5G kev sib txuas lus, quantum suav, thiab kev tiv thaiv thev naus laus zis.

XKH Services

XKH muab kev daws teeb meem rau sapphire siv lead ua kev loj hlob, suav nrog kev teeb tsa, kev ua kom zoo dua qub, thiab kev cob qhia cov neeg ua haujlwm kom ntseeg tau tias kev ua haujlwm tsis sib haum xeeb. Peb xa daim ntawv qhia kev loj hlob ua ntej (50+) haum rau ntau yam kev xav tau kev lag luam, txo R & D sijhawm rau cov neeg siv khoom. Rau cov kev siv tshwj xeeb, cov kev pabcuam kev tsim kho kom haum rau kab noj hniav (Φ200–400 mm) thiab cov tshuab doping siab heev (Cr/Ti/Ni), txhawb nqa cov khoom siv kho qhov muag thiab cov khoom siv hluav taws xob.

Cov kev pabcuam muaj nqis ntxiv suav nrog kev ua tiav tom qab kev loj hlob xws li hlais, sib tsoo, thiab polishing, ua tiav los ntawm ntau yam khoom siv sapphire xws li wafers, raj, thiab gemstone blanks. Cov kev pabcuam no txhawb nqa cov haujlwm los ntawm cov neeg siv khoom siv hluav taws xob mus rau aerospace. Peb cov kev pab txhawb nqa tau lav 24-hli warranty thiab kuaj xyuas cov chaw taws teeb hauv lub sijhawm tiag tiag, ua kom lub sijhawm poob qis thiab ua haujlwm tau zoo.