Semi-Insulating SiC Composite Substrates Dia2inch 4inch 6inch 8inch HPSI

| Cov khoom | Specification | Cov khoom | Specification |

| Txoj kab uas hla | 150 ± 0.2 hli | Pem hauv ntej (Si-face) roughness | Ra≤0.2nm (5μm * 5μm) |

| Polytype | 4 H | Ntug Chip, khawb, tawg (kev tshuaj xyuas pom) | Tsis muaj |

| Kev tiv thaiv | ≥1E8ohm·cm | TTV | ≤ 5μm |

| Hloov txheej Thickness | ≥ 0.4 m | Warp | ≤35μm |

| Tsis muaj | ≤5ea / wafer (2mm> D> 0.5mm) | Thickness | 500 ± 25 hli |

Qhov zoo ntawm semi-insulating SiC composite substrates muaj xws li:

High resistivity: semi-insulating SiC cov ntaub ntawv muaj ib tug siab resistivity, ua rau lawv me ntsis muaj peev xwm los thaiv cov dej ntws tam sim no thiab haum rau tej yam khoom siv hluav taws xob.

Kev ua haujlwm kub-kub: SiC cov ntaub ntawv muaj peev xwm ua haujlwm hauv qhov chaw kub kub, ua rau lawv tsim nyog rau kev siv hluav taws xob thiab hluav taws xob ntau zaus.

High Breakdown Voltage: SiC cov ntaub ntawv muaj lub siab tawg voltage thiab muaj peev xwm tiv taus hluav taws xob siab yam tsis muaj hluav taws xob tawg.

Chemical thiab Environmental Resistance: SiC tiv taus cov tshuaj corrosion thiab tuaj yeem tiv taus ib puag ncig hnyav rau kev thov.

Txo lub zog poob: SiC substrates tso cai rau kev hloov pauv hluav taws xob ntau dua thiab txo qis hluav taws xob hauv hluav taws xob piv rau cov khoom siv silicon ib txwm muaj.

Zuag qhia tag nrho, semi-insulating SiC composite substrates muab cov txiaj ntsig tseem ceeb hauv kev txhim kho cov khoom siv hluav taws xob ua haujlwm siab, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov uas yuav tsum tau ua haujlwm kub, siab zog ceev thiab muaj zog hloov dua siab tshiab.

Kev Muag Khoom & Kev Pabcuam Cov Neeg Siv Khoom

Kev yuav khoom

Lub chaw yuav khoom yog lub luag haujlwm los sau tag nrho cov ntaub ntawv raw xav tau los tsim koj cov khoom. Ua kom tiav traceability ntawm tag nrho cov khoom thiab cov ntaub ntawv, nrog rau cov tshuaj lom neeg thiab lub cev tsom xam yeej ib txwm muaj.

Zoo

Thaum lub sij hawm thiab tom qab lub chaw tsim khoom lossis machining ntawm koj cov khoom, lub tuam tsev tswj xyuas zoo tau koom nrog hauv kev ua kom tag nrho cov ntaub ntawv thiab kev kam rau ua tau raws li koj qhov kev qhia tshwj xeeb.

Kev pabcuam

Peb txaus siab rau peb tus kheej hauv kev muag khoom engineering nrog ntau tshaj 5 xyoo kev paub hauv kev lag luam semiconductor. Lawv raug cob qhia los teb cov lus nug txog kev ua haujlwm nrog rau muab cov lus hais raws sijhawm rau koj cov kev xav tau.

peb nyob ntawm koj ib sab los ntawm txhua lub sijhawm thaum koj muaj teeb meem, thiab daws nws hauv 10 teev.

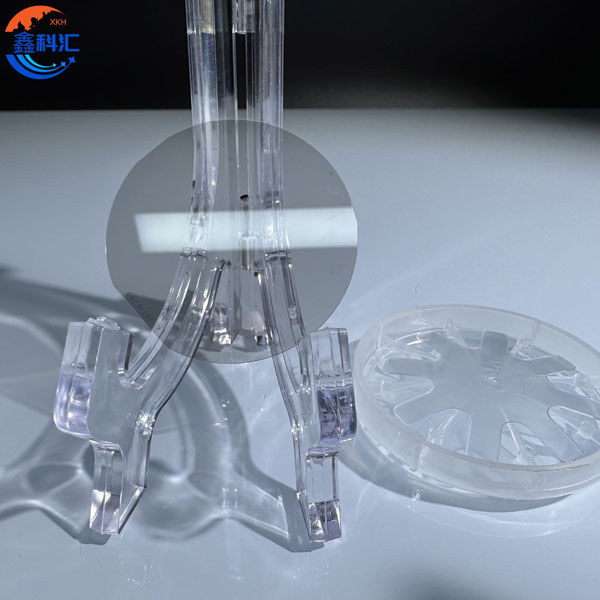

Daim duab qhia ntxaws