Semiconductor Laser Lift-Off Equipment

Daim duab qhia ntxaws

Product Overview of Laser Lift-Off Equipment

Lub Semiconductor Laser Lift-Off Equipment sawv cev rau cov kev daws teeb meem tom ntej rau kev ua haujlwm siab tshaj plaws hauv cov khoom siv semiconductor. Tsis zoo li cov txheej txheem wafering ib txwm tso siab rau kev sib tsoo tshuab, pob zeb diamond hlau sawing, los yog tshuaj-mechanical planarization, lub laser-based platform no muaj kev tiv tauj dawb, tsis muaj kev puas tsuaj rau kev tshem tawm cov txheej txheem ultra-nyias los ntawm cov khoom siv semiconductor.

Optimized rau nkig thiab cov khoom muaj nqis xws li gallium nitride (GaN), silicon carbide (SiC), sapphire, thiab gallium arsenide (GaAs), Semiconductor Laser Lift-Off Equipment enables precision slicing of wafer-scale films ncaj qha los ntawm cov siv lead ua ingot. Qhov kev siv thev naus laus zis no ua rau txo cov khoom pov tseg, txhim kho cov khoom siv, thiab txhim kho kev ncaj ncees ntawm cov substrate - tag nrho cov no yog qhov tseem ceeb rau cov khoom siv tshiab tom ntej hauv hluav taws xob hluav taws xob, RF systems, photonics, thiab micro-displays.

Nrog rau qhov tseem ceeb ntawm kev tswj tsis siv neeg, beam shaping, thiab laser-material interactivity analytics, Semiconductor Laser Lift-Off Equipment yog tsim los seamlessly integrate rau hauv semiconductor fabrication workflows thaum txhawb R & D yooj thiab loj ntau lawm scalability.

Technology & Kev Ua Haujlwm Txoj Cai ntawm Laser Lift-Off Equipment

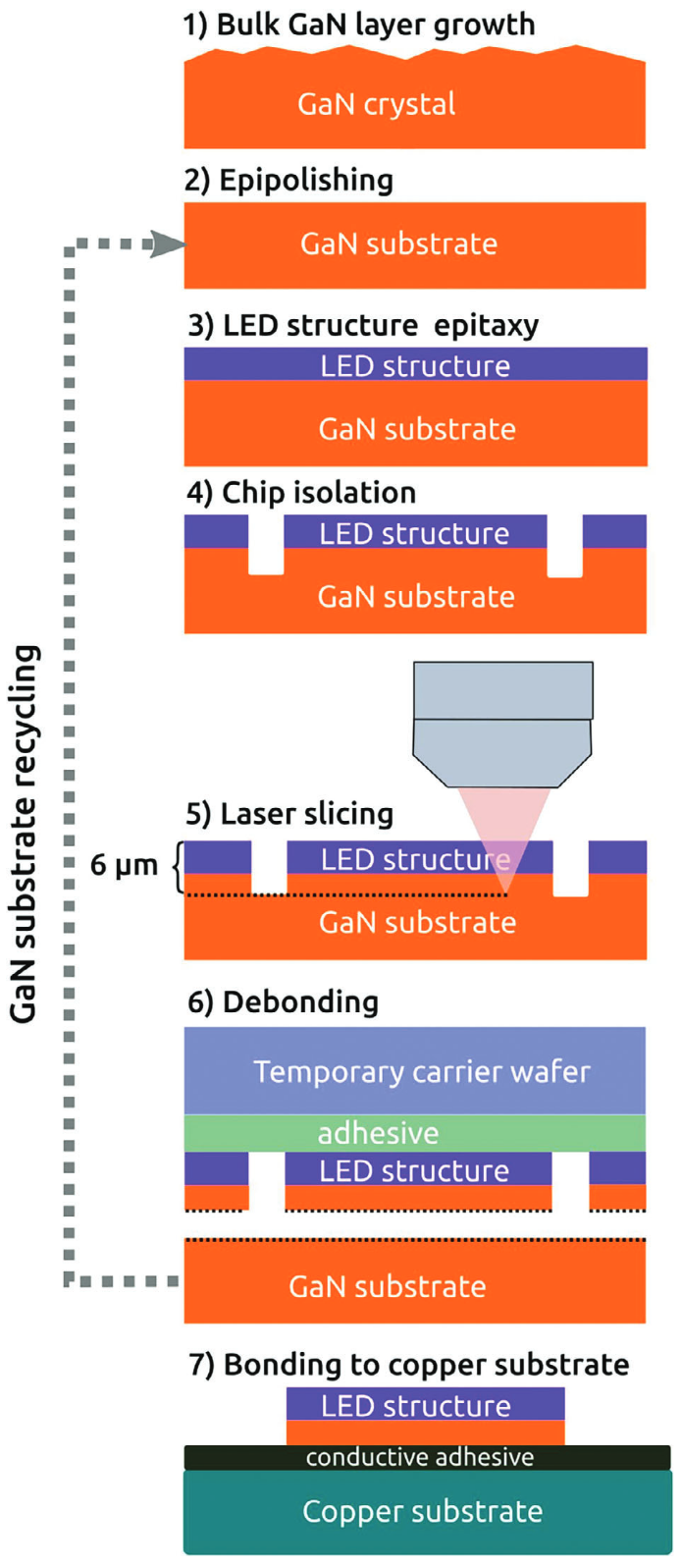

Cov txheej txheem ua los ntawm Semiconductor Laser Lift-Off Equipment pib los ntawm irradiating tus pub ingot los ntawm ib sab siv lub zog siab ultraviolet laser beam. Cov nqaj no yog nruj nreem tsom rau ntawm qhov tob hauv qhov tshwj xeeb, feem ntau nyob rau hauv ib qho kev sib txuas ua ke, qhov twg lub zog nqus tau zoo tshaj plaws vim qhov muag pom, thermal, lossis tshuaj lom neeg sib txawv.

Ntawm cov txheej txheem nqus hluav taws xob no, cov cua kub hauv zos ua rau muaj kev tawg sai sai, nthuav dav roj, lossis kev puas tsuaj ntawm cov txheej txheem ntawm lub ntsej muag (xws li, zaj duab xis stressor lossis oxide sacrificial). Qhov kev tswj xyuas meej meej no ua rau cov txheej txheem crystalline sab saud - nrog lub thickness ntawm kaum ntawm micrometers - kom tshem tawm ntawm lub hauv paus ingot kom huv si.

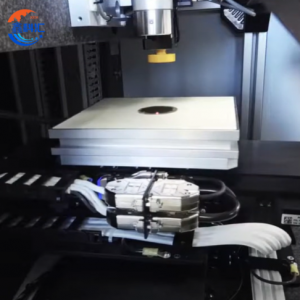

Lub Semiconductor Laser Lift-Off Equipment leverages motion-synchronized scanning heads, programmable z-axis control, thiab real-time reflectometry kom ntseeg tau tias txhua tus mem tes muab lub zog raws nraim ntawm lub hom phiaj dav hlau. Cov cuab yeej tseem tuaj yeem teeb tsa nrog burst-hom lossis ntau-pulse muaj peev xwm los txhim kho kev sib tw du thiab txo qis kev ntxhov siab. Qhov tseem ceeb, vim hais tias lub laser beam yeej tsis tiv nrog cov khoom ntawm lub cev, qhov kev pheej hmoo ntawm microcracking, bowing, los yog nto chipping yog heev txo.

Qhov no ua rau lub laser nqa-tawm thinning txoj kev ua si-hloov, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov uas ultra-flat, ultra-thin wafers yuav tsum tau nrog sub-micron TTV (tag nrho Thickness Variation).

Parameter ntawm Semiconductor Laser Lift-Off Equipment

| Lub wavelength | IR/SHG/THG/FHG |

|---|---|

| Pulse Dav | Nanosecond, Picosecond, Femtosecond |

| Optical System | Kho qhov muag kho qhov muag lossis Galvano-optical system |

| XY theem | 500 hli × 500 hli |

| Kev Ua Ntau Yam | 160 hli |

| Kev nrawm nrawm | Max 1,000 mm / sec |

| Rov ua dua | ± 1 μm lossis tsawg dua |

| Qhov tseeb qhov tseeb: | ± 5 μm lossis tsawg dua |

| Wafer Loj | 2-6 nti lossis customized |

| Tswj | Windows 10,11 thiab PLC |

| Fais fab mov Voltage | AC 200V ± 20V, Ib theem, 50/60 kHz |

| Sab nraud Dimensions | 2400 hli (W) × 1700 hli (D) × 2000 hli (H) |

| Qhov hnyav | 1,000 kg |

Muaj kev siv ntawm Laser Lift-Off Equipment

Semiconductor Laser Lift-Off Equipment yog hloov pauv sai npaum li cas cov ntaub ntawv tau npaj hla ntau yam khoom siv semiconductor:

- Ntsug GaN Fais Fab Cov Cuab Yeej ntawm Laser Lift-Off Equipment

Kev tshem tawm ntawm ultra-nyias GaN-on-GaN cov yeeb yaj kiab los ntawm cov khoom lag luam loj ua rau cov qauv kev ua haujlwm ntsug thiab rov siv cov khoom kim heev.

- SiC Wafer Thinning rau Schottky thiab MOSFET Devices

Txo cov cuab yeej txheej tuab thaum khaws cia substrate planarity - zoo tagnrho rau kev hloov hluav taws xob ceev ceev.

- Sapphire-raws li LED thiab cov khoom siv ntawm Laser Lift-Off Equipment

Ua kom muaj kev sib cais zoo ntawm cov txheej txheem ntawm sapphire boules los txhawb nyias, thermally optimized micro-LED ntau lawm.

- III-V Material Engineering ntawm Laser Lift-Off Equipment

Yooj yim rau kev tshem tawm ntawm GaAs, InP, thiab AlGaN txheej rau kev sib koom ua ke ntawm optoelectronic siab heev.

- Nyias-wafer IC thiab Sensor Fabrication

Ua cov txheej txheem ua haujlwm nyias rau kev ntsuas siab, ntsuas ntsuas, lossis photodiodes, qhov ntau yog qhov ua haujlwm tsis zoo.

- Flexible thiab Transparent Electronics

Npaj ultra-thin substrates haum rau cov lus qhia tau yooj yim, cov khoom siv hluav taws xob, thiab cov qhov rais ntse pob tshab.

Hauv txhua qhov chaw no, Semiconductor Laser Lift-Off Equipment plays lub luag haujlwm tseem ceeb hauv kev ua kom cov khoom siv me me, rov siv dua, thiab cov txheej txheem yooj yim.

Cov lus nug nquag nug (FAQ) ntawm Laser Lift-Off Equipment

Q1: Dab tsi yog qhov tsawg kawg nkaus thickness kuv tuaj yeem ua tiav siv Semiconductor Laser Lift-Off Equipment?

A1:Feem ntau ntawm 10-30 microns nyob ntawm cov khoom siv. Cov txheej txheem muaj peev xwm ntawm cov txiaj ntsig thinner nrog kev hloov kho teeb tsa.

Q2: Qhov no puas tuaj yeem siv los txiav ntau lub wafers los ntawm tib lub ingot?

A2:Yog lawm. Ntau tus neeg siv khoom siv cov txheej txheem laser nqa tawm los ua cov txheej txheem rho tawm ntawm ntau txheej nyias los ntawm ib qho ingot.

Q3: Dab tsi kev nyab xeeb nta suav nrog rau kev ua haujlwm siab lub zog laser?

A3:Class 1 enclosures, interlock systems, beam shielding, thiab automated shutoffs yog txhua tus qauv.

Q4: Qhov system no piv rau pob zeb diamond hlau saws li cas ntawm tus nqi?

A4:Thaum pib capex tej zaum yuav siab dua, laser lift-off drastic txo cov nqi consumable, substrate puas, thiab tom qab ua cov kauj ruam - txo nqi tag nrho cov tswv cuab (TCO) mus sij hawm ntev.

Q5: Puas yog cov txheej txheem scalable rau 6-nti lossis 8-nti ingots?

A5:kiag li. Lub platform txhawb nqa txog li 12-nti substrates nrog cov kab teeb pom kev zoo sib xws thiab cov theem ua haujlwm loj.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.