Semiconductor Laser Lift-Off Equipment Revolutionize Ingot Thinning

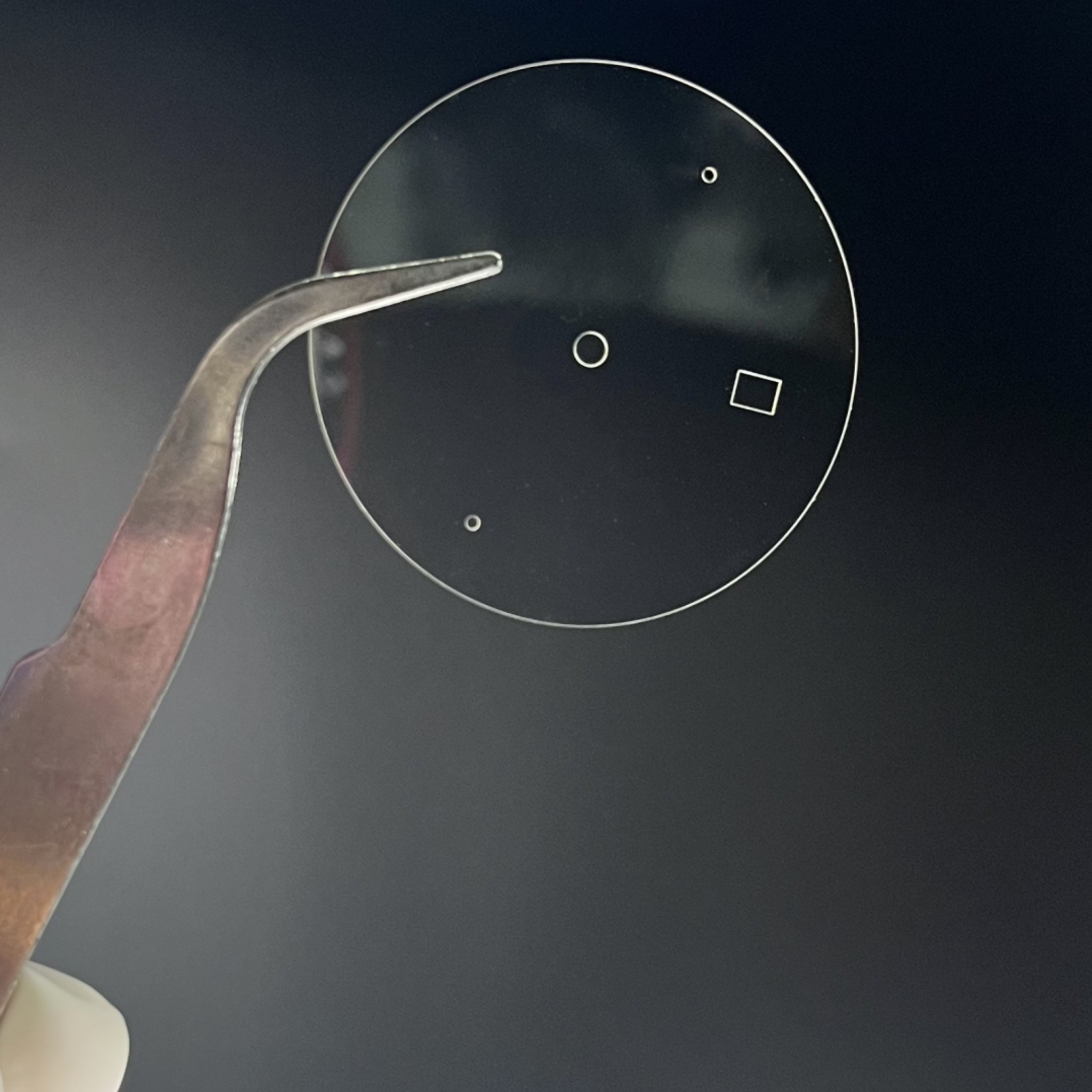

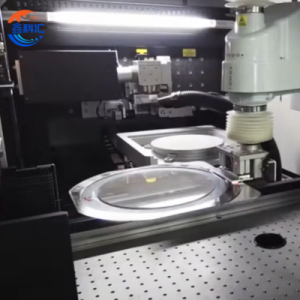

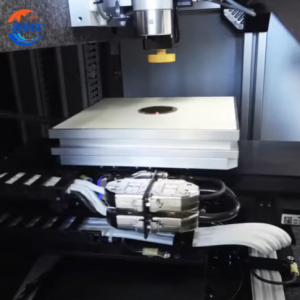

Daim duab qhia ntxaws

Khoom Taw qhia ntawm Semiconductor Laser Lift-Off Equipment

Lub Semiconductor Laser Lift-Off Equipment yog ib qho kev lag luam tshwj xeeb uas tsim los rau qhov tseeb thiab tsis sib cuag thinning ntawm semiconductor ingots los ntawm laser-induced lift-off cov tswv yim. Qhov kev tshaj lij no ua lub luag haujlwm tseem ceeb hauv cov txheej txheem semiconductor wafering niaj hnub, tshwj xeeb tshaj yog nyob rau hauv kev tsim cov khoom siv ultra-thin wafers rau cov khoom siv hluav taws xob ua tau zoo, LEDs, thiab RF khoom siv. Los ntawm kev ua kom muaj kev sib cais ntawm nyias txheej los ntawm tej ingots los yog pub substrates, Semiconductor Laser Lift-Off Equipment revolutionizes ingot thinning los ntawm kev tshem tawm txhua yam sawing, sib tsoo, thiab tshuaj etching cov kauj ruam.

Ib txwm thinning ntawm semiconductor ingots, xws li gallium nitride (GaN), silicon carbide (SiC), thiab sapphire, feem ntau siv zog, nkig, thiab ua rau microcracks lossis deg puas tsuaj. Hauv qhov sib piv, Semiconductor Laser Lift-Off Equipment muaj qhov tsis muaj kev puas tsuaj, qhov tseeb lwm txoj hauv kev uas txo cov khoom poob thiab qhov kev ntxhov siab thaum nce kev tsim khoom. Nws txhawb nqa ntau yam crystalline thiab cov ntaub ntawv sib xyaw thiab tuaj yeem sib xyaw ua ke rau hauv pem hauv ntej-kawg lossis midstream semiconductor cov kab ntau lawm.

Nrog rau configurable laser wavelengths, adaptive focus systems, thiab nqus-tshaj wafer chucks, cov khoom no tshwj xeeb tshaj yog zoo-suited rau ingot slicing, lamella creation, thiab ultra-thin film detachment rau ntsug ntaus qauv los yog heteroepitaxial txheej hloov.

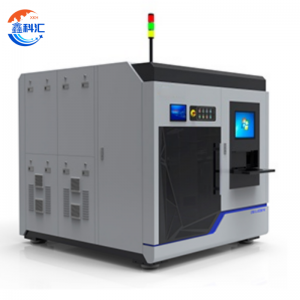

Parameter ntawm Semiconductor Laser Lift-Off Equipment

| Lub wavelength | IR/SHG/THG/FHG |

|---|---|

| Pulse Dav | Nanosecond, Picosecond, Femtosecond |

| Optical System | Kho qhov muag kho qhov muag lossis Galvano-optical system |

| XY theem | 500 hli × 500 hli |

| Kev Ua Ntau Yam | 160 hli |

| Kev nrawm nrawm | Max 1,000 mm / sec |

| Rov ua dua | ± 1 μm lossis tsawg dua |

| Qhov tseeb qhov tseeb: | ± 5 μm lossis tsawg dua |

| Wafer Loj | 2-6 nti lossis customized |

| Tswj | Windows 10,11 thiab PLC |

| Fais fab mov Voltage | AC 200V ± 20V, Ib theem, 50/60 kHz |

| Sab nraud Dimensions | 2400 hli (W) × 1700 hli (D) × 2000 hli (H) |

| Qhov hnyav | 1,000 kg |

Txoj Cai Ua Haujlwm ntawm Semiconductor Laser Lift-Off Equipment

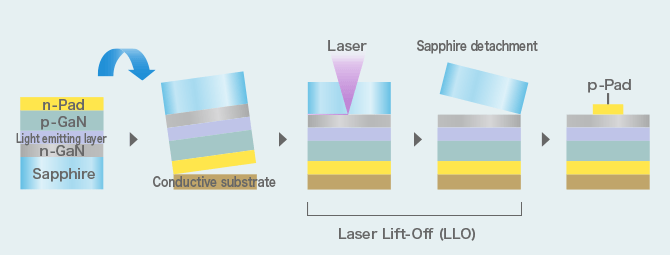

Cov txheej txheem tseem ceeb ntawm Semiconductor Laser Lift-Off Equipment cia siab rau kev xaiv photothermal decomposition lossis ablation ntawm qhov sib cuam tshuam ntawm tus neeg pub khoom noj thiab cov txheej txheem epitaxial lossis lub hom phiaj. Lub zog siab UV laser (feem ntau KrF ntawm 248 nm lossis solid-state UV lasers nyob ib ncig ntawm 355 nm) yog tsom los ntawm pob tshab lossis ib nrab pob tshab pub khoom, qhov twg lub zog yog xaiv absorbed ntawm qhov tob uas tau txiav txim siab.

Qhov kev nqus hluav taws xob hauv cheeb tsam no ua rau lub zog siab siab los yog thermal expansion txheej ntawm lub interface, uas pib ua kom huv si delamination ntawm sab sauv wafer lossis txheej txheej los ntawm lub hauv paus ingot. Cov txheej txheem yog finely tuned los ntawm kev kho cov tsis xws li mem tes dav, laser fluence, scanning ceev, thiab z-axis focal tob. Qhov tshwm sim yog ib daim nyias nyias-feem ntau nyob rau hauv 10 mus rau 50 µm ntau yam-ua kom huv si sib cais los ntawm niam txiv ingot yam tsis muaj kev puas tsuaj.

Txoj kev no ntawm laser lift-off rau ingot thinning zam lub kerf poob thiab nto puas cuam tshuam nrog pob zeb diamond hlau sawing los yog mechanical lapping. Nws kuj tseem khaws cia siv lead ua kev ncaj ncees thiab txo qis cov kev xav tau polishing, ua Semiconductor Laser Lift-Off Equipment ib qho kev ua si-hloov cov cuab yeej rau kev tsim khoom wafer tom ntej.

Kev siv ntawm Semiconductor Laser Lift-Off Equipment

Semiconductor Laser Lift-Off Equipment pom dav siv nyob rau hauv ingot thinning hla ntau yam khoom siv siab heev thiab cov cuab yeej siv, suav nrog:

-

GaN thiab GaAs Ingot Thinning rau cov khoom siv fais fab

Ua kom nyias wafer tsim rau kev ua haujlwm siab, tsis tshua muaj zog transistors thiab diodes.

-

SiC Substrate Reclamation thiab Lamella Separation

Tso cai wafer-scale nqa-tawm los ntawm tej SiC substrates rau ntsug ntaus qauv thiab wafer rov siv dua.

-

LED Wafer Slicing

Yooj yim nqa-tawm ntawm GaN txheej los ntawm tuab sapphire ingots los tsim ultra-thin LED substrates.

-

RF thiab Microwave Device Fabrication

Txhawb ultra-thin high-electron-mobility transistor (HEMT) cov qauv xav tau hauv 5G thiab radar systems.

-

Epitaxial Txheej Hloov

Precisely detaches epitaxial khaubncaws sab nraud povtseg ntawm crystalline ingots rau reuse los yog kev koom ua ke rau hauv heterostructures.

-

Nyias-Film Solar Cells thiab Photovoltaics

Siv los cais nyias cov khaubncaws sab nraud povtseg kom yoog raws lossis ua haujlwm siab hnub ci.

Nyob rau hauv txhua qhov ntawm no, Semiconductor Laser Lift-Off Equipment muab kev tswj tsis sib xws ntawm cov thickness uniformity, nto zoo, thiab txheej kev ncaj ncees.

Qhov zoo ntawm Laser-Based Ingot Thinning

-

Zero-Kerf Material Loss

Piv rau cov txheej txheem wafer slicing ib txwm, cov txheej txheem laser ua rau ze li 100% kev siv cov khoom siv.

-

Tsawg kawg Kev Nyuaj Siab thiab Warping

Non-contact lift-off eliminates mechanical vibration, txo wafer hneev thiab microcrack tsim.

-

Nto Zoo Preservation

Tsis muaj qhov tom qab thinning lapping lossis polishing yuav tsum tau muaj nyob rau hauv ntau qhov xwm txheej, raws li laser nqa-tawm khaws cia rau saum npoo kev ncaj ncees.

-

High Throughput thiab Automation Npaj

Muaj peev xwm ua tau ntau pua lub substrates rau ib qho kev ua haujlwm nrog automated loading / unloading.

-

Adaptable rau ntau yam ntaub ntawv

Tau tshaj GaN, SiC, sapphire, GaAs, thiab tawm III-V cov ntaub ntawv.

-

Environmentally Safer

Txo kev siv cov abrasives thiab cov tshuaj hnyav hnyav hauv cov txheej txheem slurry-based thinning.

-

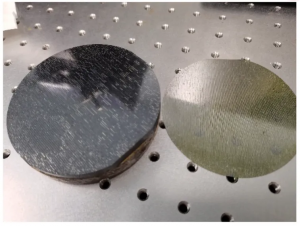

Reused substrate

Cov khoom pub dawb tuaj yeem rov ua dua rau ntau lub voj voog nqa tawm, txo cov nqi khoom siv.

Cov lus nug nquag nug (FAQ) ntawm Semiconductor Laser Lift-Off Equipment

-

Q1: Lub thickness ntau npaum li cas tuaj yeem ua Semiconductor Laser Lift-Off Equipment ua tiav rau wafer hlais?

A1:Tej daim thickness yog li ntawm 10 µm mus rau 100 µm nyob ntawm seb cov khoom thiab kev teeb tsa.Q2: Cov khoom siv no puas tuaj yeem siv los ua nyias cov khoom siv opaque zoo li SiC?

A2:Yog lawm. Los ntawm kev kho lub laser wavelength thiab optimizing interface engineering (xws li, sacrificial interlayers), txawm tias cov ntaub ntawv opaque ib nrab tuaj yeem ua tiav.Q3: Yuav ua li cas yog tus pub substrate ua ntej laser nqa-tawm?

A3:Lub kaw lus siv sub-micron vision-based alignment modules nrog cov lus tawm tswv yim los ntawm cov cim fiducial thiab scans nto.Q4: Dab tsi yog lub sij hawm uas yuav tsum tau ua rau ib lub laser nqa tawm?

A4:Nyob ntawm wafer loj thiab thickness, raug mus los ntawm 2 mus rau 10 feeb.Q5: Puas yog cov txheej txheem yuav tsum muaj chav huv huv?

A5:Txawm hais tias tsis tas yuav tsum tau ua, kev sib koom ua ke ntawm chav huv yog pom zoo kom muaj kev huv ntawm lub substrate thiab cov khoom siv tawm thaum lub sijhawm ua haujlwm siab.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.