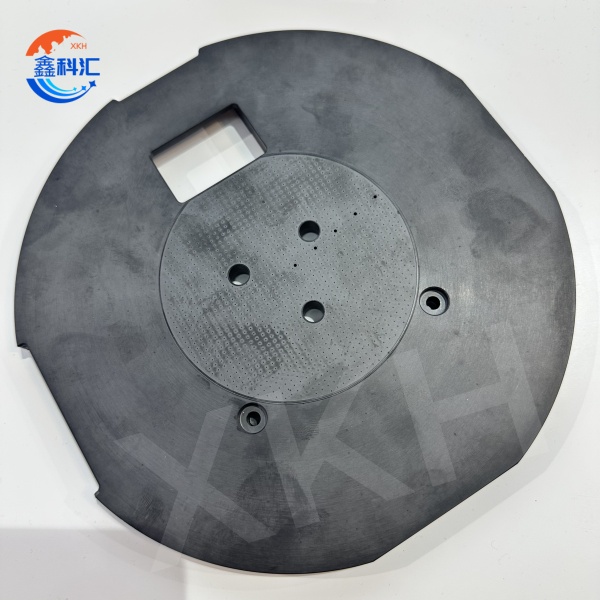

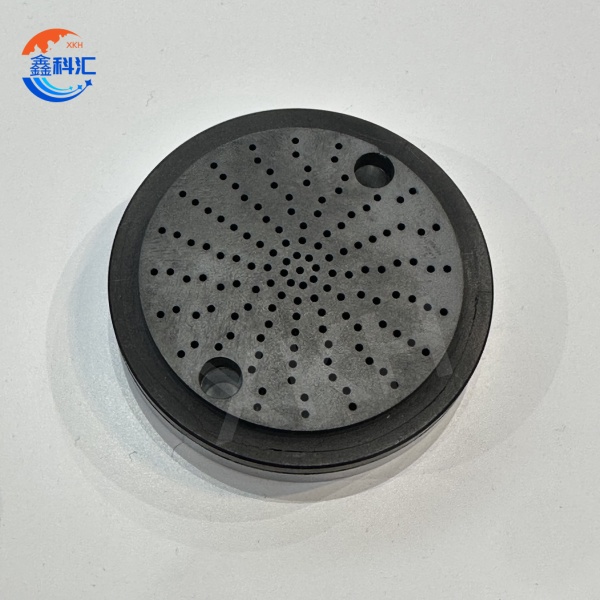

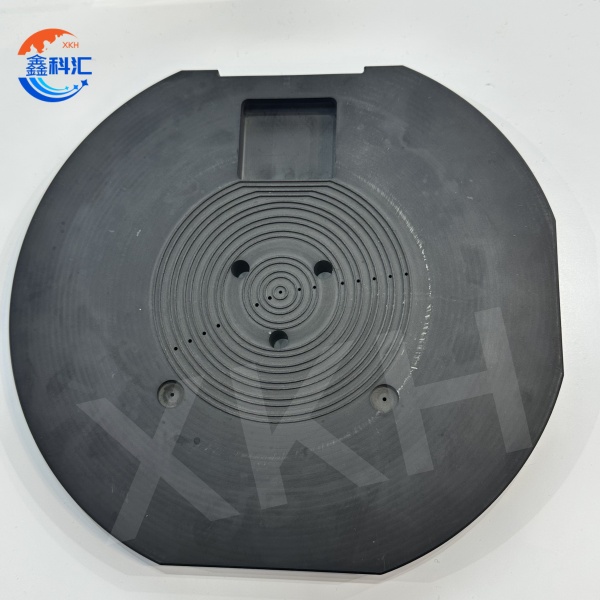

SiC ceramic chuck tais Ceramic suction khob precision machining customized

Khoom nta:

1.High hardness: Mohs hardness ntawm silicon carbide yog 9.2-9.5, thib ob tsuas yog pob zeb diamond, muaj zog hnav tsis kam.

2. Cov thermal conductivity: cov thermal conductivity ntawm silicon carbide yog siab li 120-200 W / m·K, uas muaj peev xwm dissipate tshav kub sai thiab haum rau kub kub ib puag ncig.

3. Tsawg thermal expansion coefficient: silicon carbide thermal expansion coefficient tsawg (4.0-4.5 × 10⁻⁶/K), tseem tuaj yeem tswj qhov seem stability ntawm qhov kub thiab txias.

4. Chemical stability: silicon carbide acid thiab alkali corrosion kuj, haum rau siv nyob rau hauv tshuaj corrosive ib puag ncig.

5. Cov neeg kho tshuab muaj zog: silicon carbide muaj lub zog khoov siab thiab lub zog compressive, thiab tuaj yeem tiv taus kev ntxhov siab loj.

Nta:

1.Hauv kev lag luam semiconductor, cov wafers nyias nyias yuav tsum tau muab tso rau ntawm lub tshuab nqus tsev nqus, lub tshuab nqus tsev nqus tau siv los kho cov wafers, thiab cov txheej txheem ntawm waxing, thinning, waxing, tu thiab txiav yog ua ntawm cov wafers.

2.Silicon carbide sucker muaj cov thermal conductivity zoo, tuaj yeem ua rau lub sijhawm luv luv thiab waxing, txhim kho kev tsim khoom.

3.Silicon carbide nqus nqus tsev vacuum kuj muaj cov kua qaub zoo thiab alkali corrosion kuj.

4.Piv nrog cov tsoos corundum carrier phaj, txo lub sijhawm thauj khoom thiab tshem tawm cov cua sov thiab lub sijhawm txias, txhim kho kev ua haujlwm zoo; Nyob rau tib lub sijhawm, nws tuaj yeem txo qhov hnav ntawm daim hlau sab saud thiab qis, tuav lub dav hlau zoo, thiab txuas lub neej kev pab cuam txog li 40%.

5.Cov khoom sib faib yog me me, lub teeb yuag. Nws yog qhov yooj yim dua rau cov neeg ua haujlwm nqa pallets, txo qhov kev pheej hmoo ntawm kev sib tsoo kev puas tsuaj los ntawm kev thauj mus los txog li 20%.

6.Size: siab tshaj txoj kab uas hla 640mm; Flatness: 3um lossis tsawg dua

Daim ntawv thov teb:

1. Kev tsim khoom semiconductor

● Kev ua wafer:

Rau wafer fixation nyob rau hauv photolithography, etching, nyias zaj duab xis deposition thiab lwm yam txheej txheem, kom ntseeg tau siab thiab cov txheej txheem sib xws. Nws kub thiab corrosion kuj yog haum rau hnyav semiconductor manufacturing chaw.

●Epitaxial loj hlob:

Nyob rau hauv SiC los yog GaN epitaxial kev loj hlob, raws li ib tug cab kuj rau cua sov thiab kho wafers, kom ntseeg tau tias kub uniformity thiab siv lead ua zoo nyob rau hauv high kub, kev txhim kho cov cuab yeej kev ua tau zoo.

2. Cov khoom siv hluav taws xob photoelectric

● LED Manufacturing:

Siv los kho sapphire lossis SiC substrate, thiab ua cov khoom siv cua sov hauv cov txheej txheem MOCVD, los xyuas kom meej qhov sib xws ntawm kev loj hlob ntawm epitaxial, txhim kho LED luminous efficiency thiab zoo.

● Laser diode:

Raws li lub high-precision fixture, kho thiab cua sov substrate los xyuas kom meej cov txheej txheem kub stability, txhim kho cov zis hwj chim thiab kev cia siab ntawm lub laser diode.

3. Precision machining

● Optical Cheebtsam ua:

Nws yog siv los kho qhov precision Cheebtsam xws li optical lo ntsiab muag thiab cov ntxaij lim dej kom ntseeg tau tias siab precision thiab tsis muaj kuab paug thaum ua, thiab yog tsim rau high-siv machining.

● Ceramic ua:

Raws li lub siab ruaj khov fixture, nws yog tsim rau precision machining ntawm cov ntaub ntawv ceramic los xyuas kom meej machining raug thiab sib xws nyob rau hauv kub thiab corrosive ib puag ncig.

4. Kev sim kev tshawb fawb

● Kev sim kub siab:

Raws li tus qauv fixation ntaus ntawv nyob rau hauv qhov kub thiab txias ib puag ncig, nws txhawb huab cua kub thwmsim saum 1600 ° C los xyuas kom meej kub uniformity thiab qauv stability.

● Kev kuaj lub tshuab nqus tsev:

Raws li cov qauv kho thiab cov khoom siv cua sov hauv lub tshuab nqus tsev, kom ntseeg tau tias qhov tseeb thiab rov ua dua ntawm qhov kev sim, haum rau lub tshuab nqus tsev thiab kev kho cua sov.

Technical specifications:

| (Material khoom) | (Unit) | (ssic) | |

| (SiC cov ntsiab lus) |

| (Wt)% | > 99 |

| (Average grain size) |

| micron | 4-10 |

| (Density) |

| kg/dm 3 | > 3.14 |

| (Tshooj porosity) |

| Vo 1% | <0.5 |

| (Vickers hardness) | HV 0.5 | GPa | 28 |

| * (Flexural zog) | 20ºC tso | MPa | 450 |

| (Compressive zog) | 20ºC tso | MPa | 3900 ib |

| (Elastic Modulus) | 20ºC tso | GPa | 420 |

| (Fracture toughness) |

| MPa / m '% | 3.5 |

| (Thermal conductivity) | 20°C kub | W / (m * K) | 160 |

| (Resistivity) | 20°C kub | Aw.cm | 106-108 : kuv |

|

| ib (RT**...80ºC) | K-1 * 10-6 | 4.3 |

|

|

| oºC ua | 1700 |

Nrog rau xyoo ntawm kev sib sau ua ke thiab kev lag luam kev lag luam, XKH muaj peev xwm kho qhov tseem ceeb xws li qhov loj me, cua sov txoj kev thiab lub tshuab nqus tsev adsorption tsim ntawm chuck raws li cov kev xav tau tshwj xeeb ntawm cov neeg siv khoom, kom ntseeg tau tias cov khoom lag luam zoo haum rau cov neeg siv khoom. SiC silicon carbide ceramic chucks tau dhau los ua cov khoom tseem ceeb hauv kev ua wafer, kev loj hlob ntawm epitaxial thiab lwm yam txheej txheem tseem ceeb vim lawv cov thermal conductivity zoo, kub stability thiab tshuaj stability. Tshwj xeeb tshaj yog nyob rau hauv kev tsim cov khoom siv semiconductor thib peb xws li SiC thiab GaN, qhov kev thov rau silicon carbide ceramic chucks txuas ntxiv mus. Nyob rau hauv lub neej yav tom ntej, nrog rau kev loj hlob sai ntawm 5G, hluav taws xob tsheb, kev txawj ntse txawj ntse thiab lwm yam technologies, daim ntawv thov prospects ntawm silicon carbide ceramic chucks nyob rau hauv lub semiconductor kev lag luam yuav dav dua.

Daim duab qhia ntxaws