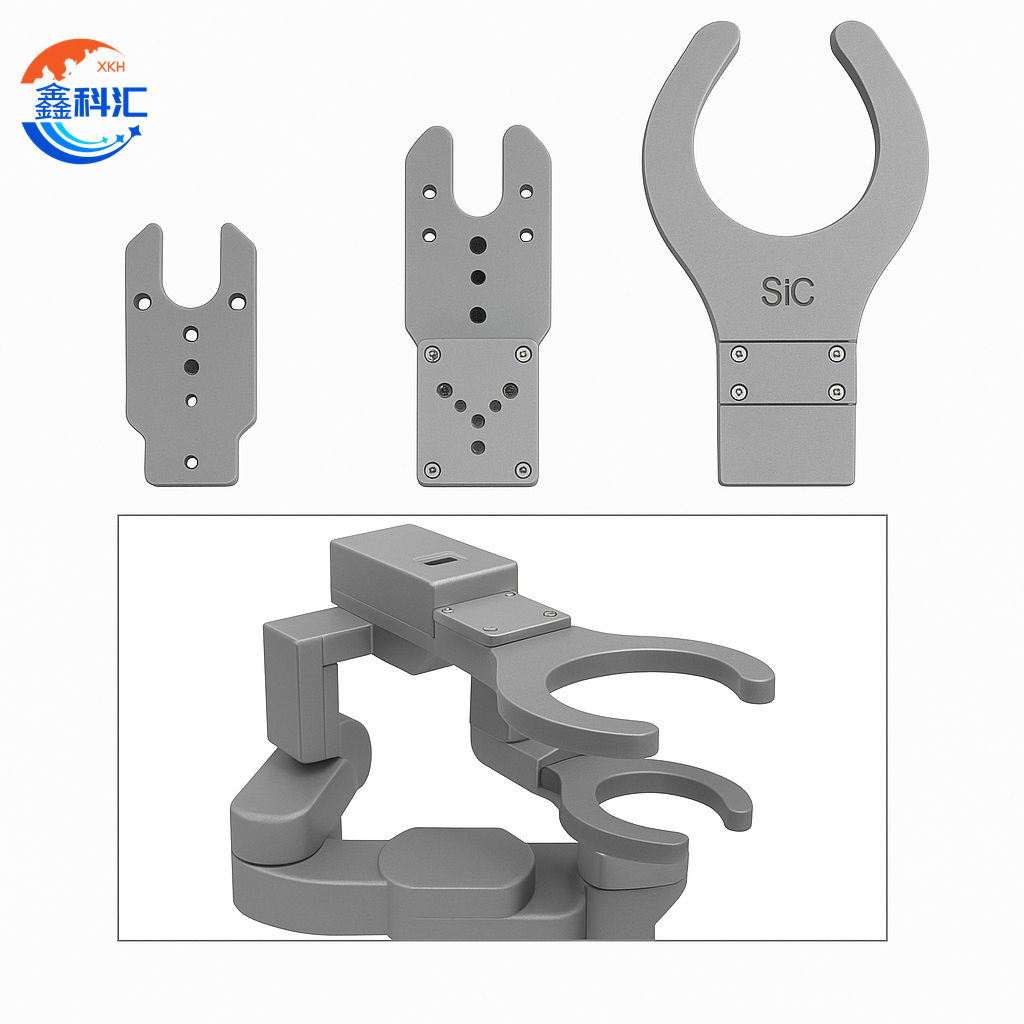

SiC ceramic kawg effector tuav caj npab rau wafer carring

SiC ceramic kawg effector Abstract

Lub SiC (Silicon Carbide) ceramic kawg-effector yog ib qho tseem ceeb ntawm cov khoom siv high-precision wafer tuav siv nyob rau hauv semiconductor manufacturing thiab advanced microfabrication ib puag ncig. Kev tsim kho kom tau raws li qhov xav tau ntawm ultra-ntxuav, kub-kub, thiab ib puag ncig ruaj khov, qhov tshwj xeeb kawg-effector ua kom ntseeg tau thiab tsis muaj paug tsis muaj kev thauj mus los ntawm wafers thaum lub sij hawm tsim khoom tseem ceeb xws li lithography, etching, thiab deposition.

Siv cov khoom siv zoo tshaj plaws ntawm silicon carbide-xws li cov thermal conductivity, huab cua hardness, zoo heev tshuaj inertness, thiab tsawg thermal expansion-lub SiC ceramic end-effector muaj unmatched mechanical stiffness thiab dimensional stability txawm nyob rau hauv ceev thermal cycling los yog nyob rau hauv cov txheej txheem corrosive chamber. Nws cov cim tsis tshua muaj cim thiab cov yam ntxwv ntawm cov ntshav plasma ua rau nws tshwj xeeb tshaj yog haum rau kev siv chav huv huv thiab lub tshuab nqus tsev, qhov uas tswj cov wafer nto kev ncaj ncees thiab txo cov kab mob sib kis yog qhov tseem ceeb.

SiC ceramic kawg effector Daim ntawv thov

1. Semiconductor Wafer tuav

SiC ceramic kawg effectors yog dav siv nyob rau hauv lub semiconductor kev lag luam rau tuav silicon wafers thaum automated ntau lawm. Cov txiaj ntsig kawg no feem ntau yog ntsia rau ntawm caj npab neeg hlau lossis lub tshuab nqus tsev hloov pauv thiab tsim kom haum rau wafers ntawm ntau qhov ntau thiab tsawg xws li 200mm thiab 300mm. Lawv yog qhov tseem ceeb hauv cov txheej txheem suav nrog Chemical Vapor Deposition (CVD), Lub Cev Vapor Deposition (PVD), etching, thiab diffusion - qhov chaw kub siab, lub tshuab nqus tsev, thiab cov roj corrosive muaj ntau. SiC qhov tshwj xeeb thermal tsis kam thiab tshuaj lom neeg ruaj khov ua rau nws yog cov khoom siv zoo tshaj plaws los tiv thaiv cov cheeb tsam hnyav yam tsis muaj kev puas tsuaj.

2. Chav huv huv thiab lub tshuab nqus tsev sib raug zoo

Hauv chav huv huv thiab lub tshuab nqus tsev, qhov chaw sib kis yuav tsum raug txo kom tsawg, SiC ceramics muab cov txiaj ntsig tseem ceeb. Cov khoom siv ntom, du nto tawm tsam cov ntsiab lus tseem ceeb, pab tswj kev nyab xeeb thaum thauj khoom. Qhov no ua rau SiC kawg effectors tshwj xeeb tshaj yog tsim nyog rau cov txheej txheem tseem ceeb xws li Extreme Ultraviolet Lithography (EUV) thiab Atomic Layer Deposition (ALD), qhov kev huv huv yog qhov tseem ceeb. Tsis tas li ntawd, SiC qhov kev tawm dag zog qis thiab cov ntshav ntshav siab ua kom ntseeg tau tias muaj kev ua tau zoo hauv lub tshuab nqus tsev, ua kom lub neej ntev ntawm cov cuab yeej thiab txo cov zaus txij nkawm.

3. High-Precision Positioning Systems

Precision thiab ruaj khov yog qhov tseem ceeb hauv kev ua haujlwm siab wafer, tshwj xeeb tshaj yog nyob rau hauv metrology, tshuaj xyuas, thiab cov khoom sib dhos. SiC ceramics muaj cov coefficient tsawg heev ntawm thermal expansion thiab siab nruj, uas tso cai rau qhov kawg effector tswj nws cov txheej txheem raug txawm nyob rau hauv thermal cycling los yog mechanical load. Qhov no ua kom ntseeg tau tias wafers nyob twj ywm raws nraim thaum lub sij hawm thauj, txo qhov kev pheej hmoo ntawm micro-scratches, misalignment, los yog ntsuas qhov yuam kev - cov ntsiab lus tseem ceeb ntawm cov txheej txheem sub-5nm.

SiC ceramic kawg effector Khoom

1. Cov neeg kho tshuab siab zog thiab hardness

SiC ceramics muaj lub zog tshwj xeeb, nrog lub zog flexural feem ntau tshaj 400 MPa thiab Vickers hardness qhov tseem ceeb tshaj 2000 HV. Qhov no ua rau lawv tiv taus ntau yam kev ntxhov siab, cuam tshuam, thiab hnav, txawm tias tom qab siv sijhawm ntev. Lub siab rigidity ntawm SiC kuj txo qis deflection thaum lub sij hawm high-ceev wafer hloov tsheb, xyuas kom meej thiab rov ua dua.

2. Zoo heev thermal stability

Ib qho ntawm cov khoom tseem ceeb tshaj plaws ntawm SiC ceramics yog lawv lub peev xwm tiv taus qhov kub thiab txias - feem ntau mus txog 1600 ° C nyob rau hauv inert atmospheres - tsis poob txhua yam kev ncaj ncees. Lawv cov coefficient qis ntawm thermal expansion (~ 4.0 x 10⁻⁶ / K) ua kom muaj kev ruaj ntseg nyob rau hauv thermal cycling, ua rau lawv zoo tagnrho rau cov ntawv thov xws li CVD, PVD, thiab kub-kub annealing.

SiC ceramic kawg effector Q&A

Q: Cov khoom siv dab tsi yog siv hauv wafer end effector?

A:Wafer kawg effectors feem ntau yog tsim los ntawm cov ntaub ntawv uas muaj lub zog siab, thermal stability, thiab tsis tshua muaj particle tiam. Ntawm cov no, Silicon Carbide (SiC) ceramic yog ib qho ntawm cov khoom siv siab tshaj plaws thiab nyiam tshaj plaws. SiC ceramics yog ib qho nyuaj heev, thermally ruaj khov, chemically inert, thiab resistant rau hnav, ua rau lawv zoo tagnrho rau tuav cov mos silicon wafers nyob rau hauv huv chav tsev thiab lub tshuab nqus tsev ib puag ncig. Piv rau quartz lossis coated hlau, SiC muaj kev ruaj ntseg zoo tshaj plaws nyob rau hauv qhov kub thiab txias thiab tsis tso cov khoom, uas pab tiv thaiv kev sib kis.