SiC Ceramic Tais rau Wafer Carrier nrog High-Temperature Resistance

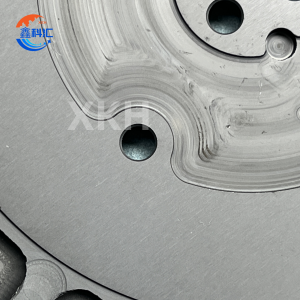

Silicon Carbide Ceramic Tais (SiC Tray)

Ib qho kev ua haujlwm siab ntawm cov khoom siv ceramic raws li cov khoom siv silicon carbide (SiC), engineered rau kev lag luam siab heev xws li semiconductor manufacturing thiab LED ntau lawm. Nws cov haujlwm tseem ceeb suav nrog kev ua haujlwm raws li tus neeg nqa khoom wafer, etching txheej txheem platform, lossis kev txhawb nqa cov txheej txheem kub, leveraging exceptional thermal conductivity, high-temperature resistance, thiab tshuaj stability kom paub meej cov txheej txheem uniformity thiab cov khoom yield.

Ntsiab nta

1. Thermal Performance

- High Thermal Conductivity : 140-300 W / m·K, ua tau zoo tshaj li cov graphite ib txwm muaj (85 W / m·K), ua kom cov cua sov sai sai thiab txo cov thermal stress.

- Tsawg Thermal Expansion Coefficient : 4.0 × 10⁻⁶ / ℃ (25–1000 ℃), zoo sib xws silicon (2.6 × 10⁻⁶ / ℃), txo qis thermal deformation txaus ntshai.

2. Mechanical Properties

- Lub zog siab: Flexural zog ≥320 MPa (20 ℃), tiv taus compression thiab cuam tshuam.

- High Hardness : Mohs hardness 9.5, thib ob tsuas yog pob zeb diamond, muab kev hnav zoo dua.

3. Tshuaj Stability

- Corrosion Resistance : Resistant rau muaj zog acids (xws li, HF, H₂SO₄), haum rau etching txheej txheem ib puag ncig.

- Tsis-Magnetic: Intrinsic magnetic susceptibility <1 × 10⁻⁶ emu/g, tsis txhob cuam tshuam nrog precision instruments.

4. Ib puag ncig kev kam rau siab heev

- High-Temperature Durability : Lub sij hawm ntev ua haujlwm kub txog 1600-1900 ℃; Lub sij hawm luv luv mus txog 2200 ℃ (ib puag ncig tsis muaj oxygen).

- Thermal Shock Resistance : Withstands abrupt kub hloov (ΔT > 1000 ℃) tsis muaj cracking.

Daim ntawv thov

| Daim ntawv thov teb | Cov xwm txheej tshwj xeeb | Technical tus nqi |

| Semiconductor Manufacturing | Wafer etching (ICP), thin-film deposition (MOCVD), CMP polishing | High thermal conductivity ua kom qhov kub tsis sib xws; Tsawg thermal expansion minimizes wafer warpage. |

| LED Production | Epitaxial kev loj hlob (piv txwv li, GaN), wafer dicing, ntim | Txhawb nqa ntau yam tsis xws luag, txhim kho LED luminous efficiency thiab lifespan. |

| Photovoltaic kev lag luam | Silicon wafer sintering furnaces, PECVD cov khoom txhawb nqa | High-temperature thiab thermal shock kuj ua rau cov khoom siv lifespan. |

| Laser & Optics | High-power laser txias substrates, optical system txhawb nqa | High thermal conductivity enables sai sai tshav kub dissipation, stabilizing optical Cheebtsam. |

| Analytical Instruments | TGA/DSC cov qauv tuav | Tsawg tshav kub muaj peev xwm thiab ceev thermal teb txhim kho kev ntsuas qhov tseeb. |

Cov khoom zoo

- Kev Ua Haujlwm Zoo: Cov thermal conductivity, lub zog, thiab corrosion kuj deb tshaj alumina thiab silicon nitride ceramics, ua tau raws li qhov xav tau ntawm kev ua haujlwm hnyav.

- Lub teeb yuag: Qhov ntom ntawm 3.1-3.2 g / cm³ (40% ntawm cov hlau), txo qis inertial load thiab txhim kho cov lus tsa suab.

- Longevity & Reliability : Kev pab lub neej ntev tshaj li 5 xyoos ntawm 1600 ℃, txo qis sijhawm thiab txo cov nqi ua haujlwm los ntawm 30%.

- Customization : Txhawb txoj kev geometries (xws li, lub khob nqus dej, cov tais ntau txheej) nrog kev ua yuam kev flatness <15 μm rau cov ntawv thov raug.

Technical Specifications

| Parameter Category | Qhov taw qhia |

| Lub cev muaj zog | |

| Qhov ntom | ≥3.10g / cm³ |

| Flexural zog (20 ℃) | 320-410 MPa |

| Thermal conductivity (20 ℃) | 140-300 W / (m·K) |

| Thermal Expansion Coefficient (25-1000 ℃) | 4.0 × 10⁻⁶ / ℃ |

| Chemical Properties | |

| Acid Resistance (HF/H₂SO₄) | Tsis muaj corrosion tom qab 24h immersion |

| Machining Precision | |

| Flatness | ≤15 μm (300 × 300 hli) |

| Nto Roughness (Ra) | ≤0.4 hli |

XKH's Services

XKH muab kev daws teeb meem kev lag luam thoob plaws kev txhim kho kev cai, kev ua haujlwm zoo, thiab kev tswj xyuas zoo. Rau kev tsim kho kev cai, nws muaj kev ua siab dawb huv (> 99.999%) thiab ntxeem tau (30-50% porosity) cov khoom siv daws teeb meem, ua ke nrog 3D qauv thiab simulation kom ua kom zoo dua geometries nyuaj rau kev siv xws li semiconductors thiab aerospace. Precision machining ua raws li cov txheej txheem streamlined: hmoov ua → isostatic / qhuav nias → 2200 ° C sintering → CNC / pob zeb diamond sib tsoo → tshuaj xyuas, xyuas kom meej nanometer-theem polishing thiab ± 0.01 hli qhov ntev kam rau ua. Kev tswj hwm zoo suav nrog kev sim ua tiav (XRD muaj pes tsawg leeg, SEM microstructure, 3-point dabtsi yog khoov) thiab kev txhawb nqa (kev ua kom zoo, 24/7 kev sib tham, 48-teev cov qauv xa), xa cov khoom lag luam txhim khu kev qha, kev ua haujlwm siab rau cov kev xav tau siab heev.

Cov lus nug nquag nug (FAQ)

1. Q: Dab tsi kev lag luam siv silicon carbide ceramic tais?

A: Siv dav hauv kev tsim khoom lag luam semiconductor (wafer tuav), lub hnub ci zog (PECVD txheej txheem), cov khoom siv kho mob (MRI Cheebtsam), thiab aerospace (qhov kub thiab txias) vim lawv qhov kub thiab txias tsis kam thiab tshuaj lom neeg ruaj khov.

2. Q: Ua li cas silicon carbide outperform quartz / iav tais?

A: Ntau dua thermal shock resistance (txog 1800 ° C vs. quartz's 1100 ° C), xoom sib nqus cuam tshuam , thiab lub neej ntev (5+ xyoo vs. quartz's 6-12 lub hlis).

3. Q: Puas tuaj yeem ua silicon carbide trays daws cov acidic ib puag ncig?

A: Yog. Resistant rau HF, H2SO4, thiab NaOH nrog <0.01mm corrosion/xyoo, ua rau lawv zoo tagnrho rau tshuaj etching thiab wafer tu.

4. Q: Puas yog silicon carbide trays sib haum nrog automation?

A: Yog. Tsim los rau lub tshuab nqus tsev khaws khoom thiab kev siv neeg hlau, nrog rau qhov chaw tiaj tus <0.01mm los tiv thaiv cov kab mob sib kis hauv automated fabs.

5. Q: Tus nqi sib piv piv nrog cov khoom siv li cas?

A: Tus nqi siab dua (3-5x quartz) tab sis 30-50% TCO qis vim qhov kev ncua ntev, txo qis qis, thiab kev txuag hluav taws xob los ntawm cov thermal conductivity zoo dua.