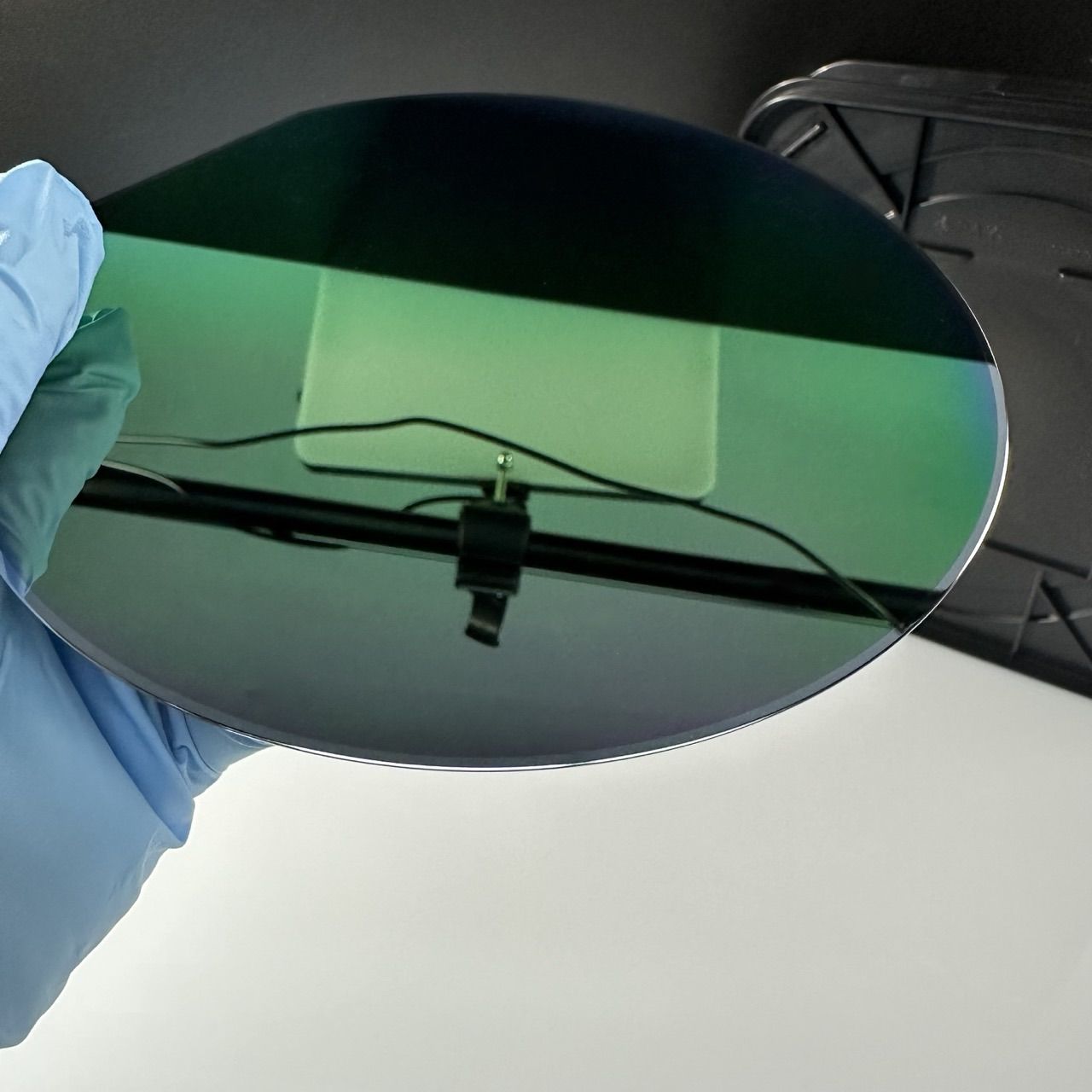

SiC Ingot Loj hlob Rauv rau Loj-inch SiC Crystal TSSG/LPE Methods

Txoj Cai Ua Haujlwm

Lub hauv paus ntsiab lus tseem ceeb ntawm cov kua-theem silicon carbide ingot kev loj hlob muaj feem cuam tshuam nrog cov khoom siv siab purity SiC hauv cov hlau molten (xws li Si, Cr) ntawm 1800-2100 ° C los tsim cov kev daws teeb meem saturated, ua raws li kev tswj kev loj hlob ntawm SiC ib leeg muaju ntawm cov noob muaju los ntawm cov kev cai ntawm qhov kub thiab txias. Cov thev naus laus zis no tshwj xeeb tshaj yog tsim rau kev ua kom muaj siab dawb huv (> 99.9995%) 4H / 6H-SiC ib leeg muaju uas tsis muaj qhov tsis xws luag (< 100 / cm²), ua tau raws li cov txheej txheem nruj me ntsis rau cov khoom siv hluav taws xob hluav taws xob thiab RF. Cov txheej txheem kev loj hlob ua kua ua rau muaj kev tswj xyuas meej ntawm cov khoom siv lead ua hluav taws xob (N / P hom) thiab kev tiv thaiv los ntawm kev ua kom zoo tshaj plaws ntawm kev daws teeb meem thiab kev loj hlob tsis zoo.

Core Components

1. Tshwj xeeb Crucible System: High-purity graphite / tantalum composite crucible, kub tsis kam> 2200 ° C, resistant rau SiC yaj corrosion.

2. Multi-zone Heating System: Kev sib xyaw ua haujlwm / induction cua sov nrog kev tswj qhov kub thiab txias ntawm ± 0.5 ° C (1800-2100 ° C ntau).

3. Precision Motion System: Dual kaw-loop tswj rau cov noob rotation (0-50rpm) thiab nqa (0.1-10mm / h).

4. Atmosphere Control System: High-purity argon/nitrogen tiv thaiv, adjustable ua hauj lwm siab (0.1-1atm).

5. Intelligent Control System: PLC + kev lag luam PC redundant tswj nrog real-time kev loj hlob interface saib xyuas.

6. Ua kom txias txias: Qib dej txias tsim kom ua haujlwm ruaj khov mus ntev.

TSSG vs. LPE Comparison

| Yam ntxwv | TSSG Method | LPE Method |

| Kev loj hlob Temp | 2000-2100 ° C | 1500-1800 ° C |

| Kev Loj Hlob | 0.2-1mm / h | 5-50μm / h |

| Crystal Loj | 4-8 nti ingots | 50-500μm epi-txheej txheej |

| Daim ntawv thov tseem ceeb | Kev npaj substrate | Lub zog ntaus ntawv epi-txheej |

| Defect Density | <500/cm² | <100/cm² |

| Tsim nyog Polytypes | 4H/6H-SiC | 4H/3C-SiC |

Cov ntawv thov tseem ceeb

1. Fais fab Electronics: 6-nti 4H-SiC substrates rau 1200V + MOSFETs / diodes.

2. 5G RF Devices: Semi-insulating SiC substrates rau hauv paus chaw nres tsheb PAs.

3. EV Daim Ntawv Thov: Ultra-thick (> 200μm) epi-txheej txheem rau automotive-qib modules.

4. PV Inverters: Tsawg-defect substrates enabling> 99% conversion efficiency.

Core Zoo

1. Kev ua tau zoo tshaj plaws

1.1 Integrated Multi-Method Design

Cov kua-theem SiC ingot txoj kev loj hlob tshiab no ua ke nrog TSSG thiab LPE siv lead ua kev loj hlob thev naus laus zis. TSSG system ntiav cov noob qoob loo saum toj kawg nkaus kev loj hlob nrog meej yaj convection thiab kub gradient tswj (ΔT≤5 ℃ / cm), ua kom ruaj khov kev loj hlob ntawm 4-8 nti loj-inch SiC ingots nrog ib leeg khiav tawm ntawm 15-20kg rau 6H / 4H-SiC muaju. Lub LPE system siv qhov ua kom zoo ntawm cov kuab tshuaj muaj pes tsawg leeg (Si-Cr alloy system) thiab kev tswj hwm supersaturation (± 1%) kom loj hlob zoo tuab tuab epitaxial txheej nrog qhov tsis xws luag ntom <100 / cm² ntawm qhov kub thiab txias (1500-1800 ℃).

1.2 Intelligent Control System

Nruab nrog 4th tiam ntse kev loj hlob tswj featuring:

• Multi-spectral in-site saib xyuas (400-2500nm wavelength range)

• Laser-raws li melt qib nrhiav kom tau (± 0.01mm precision)

• CCD-raws li txoj kab uas hla kaw-loop tswj (<± 1mm fluctuation)

• AI-powered kev loj hlob parameter optimization (15% zog txuag)

2. Cov txheej txheem ua tau zoo

2.1 TSSG Method Core Strengths

• Loj-loj muaj peev xwm: Txhawb txog li 8-nti siv lead ua loj hlob nrog> 99.5% txoj kab uas hla uniformity

• Superior crystallinity: Dislocation ceev <500/cm², micropipe ntom <5/cm²

• Doping uniformity: <8% n-hom resistivity variation (4-nti wafers)

• Optimized loj hlob tus nqi: Kho 0.3-1.2mm / h, 3-5 × sai dua vapor-phase txoj kev

2.2 LPE Method Core Strengths

• Ultra-low defect epitaxy: Interface state ntom <1×10¹¹cm⁻²·eV⁻¹

• Precise thickness tswj: 50-500μm epi-txheej nrog <± 2% thickness variation

• Tsawg-kub efficiency: 300-500 ℃ qis dua cov txheej txheem CVD

• Cov qauv kev loj hlob: Txhawb pn junctions, superlattices, thiab lwm yam.

3. Qhov Zoo Tshaj Plaws Ntau Lawm

3.1 Kev Tswj Tus Nqi

• 85% raw khoom siv (vs. 60% pa)

• 40% qis zog noj (piv rau HVPE)

• 90% khoom siv uptime (modular tsim minimizes downtime)

3.2 Quality Assurance

• 6s txheej txheem tswj (CPK> 1.67)

• Kev kuaj pom qhov tsis xws hauv online (0.1μm daws teeb meem)

• Tag nrho cov txheej txheem cov ntaub ntawv traceability (2000+ lub sijhawm tsis muaj tseeb)

3.3 Scalability

• Tau tshaj 4H/6H/3C polytypes

• Upgradeable rau 12-nti txheej txheem modules

• Txhawb SiC/GaN hetero-integration

4. Kev lag luam Daim Ntawv Thov Qhov Zoo

4.1 Cov khoom siv fais fab

• Tsawg-resistivity substrates (0.015-0.025Ω·cm) rau 1200-3300V li

• Semi-insulating substrates (> 10⁸Ω·cm) rau RF daim ntaub ntawv

4.2 Cov Kev Tsim Kho Tshiab

• Kev sib txuas lus Quantum: Ultra-tsawg suab nrov substrates (1/f suab <-120dB)

• Ib puag ncig tsis zoo: Cov muaj hluav taws xob tiv taus hluav taws xob (<5% degradation tom qab 1 × 10¹⁶n / cm² irradiation)

XKH Services

1. Customized Equipment: Tailored TSSG/LPE system configurations.

2. Kev cob qhia txheej txheem: Kev cob qhia kev cob qhia zoo.

3. Kev them nyiaj yug tom qab muag: 24/7 kev teb thiab kev saib xyuas.

4. Turnkey Solutions: Cov kev pabcuam puv npo los ntawm kev teeb tsa mus rau txheej txheem validation.

5. Khoom siv: 2-12 nti SiC substrates/epi-wafers muaj.

Cov txiaj ntsig tseem ceeb muaj xws li:

• Muaj peev xwm loj hlob txog li 8-nti crystal.

• Resistivity uniformity <0.5%.

• Cov khoom siv sijhawm ua haujlwm> 95%.

• 24/7 kev txhawb nqa.