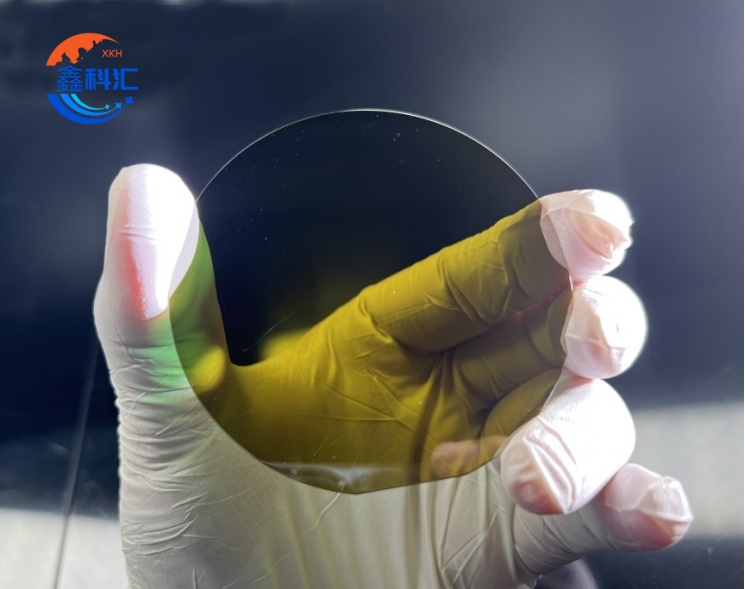

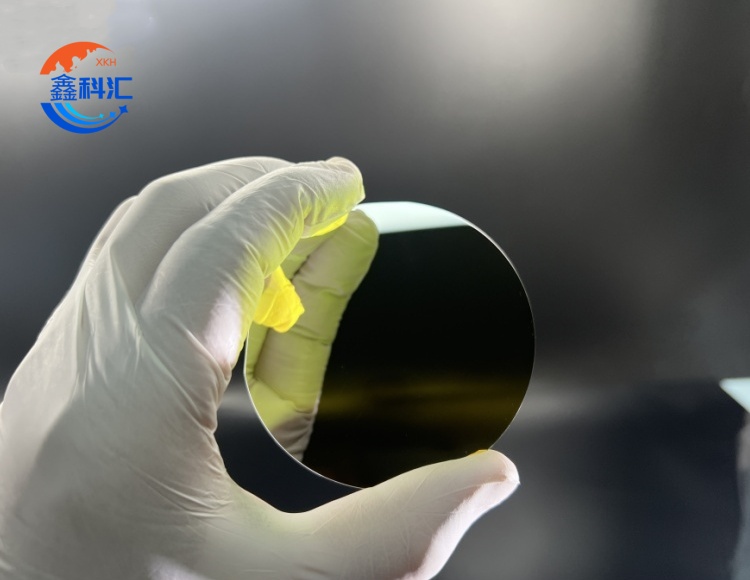

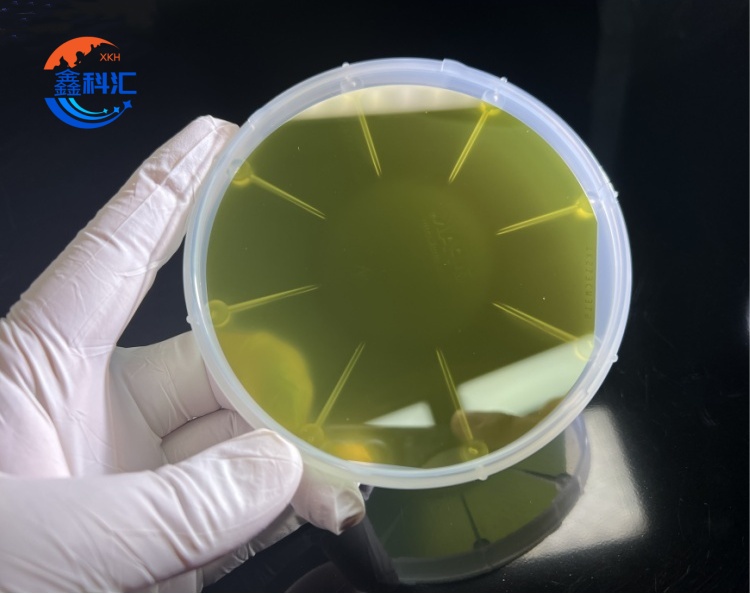

Sic Substrate Silicon Carbide Wafer 4H-N Hom Siab Hardness Corrosion Resistance Prime Qib Polishing

Cov hauv qab no yog cov yam ntxwv ntawm silicon carbide wafer

1. Cov thermal conductivity ntau dua: Cov thermal conductivity ntawm SIC wafers yog ntau dua li ntawm silicon, uas txhais tau hais tias SIC wafers tuaj yeem ua kom sov tau zoo thiab tsim nyog rau kev ua haujlwm hauv qhov kub thiab txias.

2. Cov khoom siv hluav taws xob ntau dua: SIC wafers muaj cov khoom siv hluav taws xob ntau dua li silicon, tso cai rau SIC cov cuab yeej ua haujlwm ntawm qhov nrawm dua.

3. Cov khoom siv hluav taws xob ntau dua: SIC wafer cov khoom siv hluav taws xob ntau dua, ua rau nws tsim nyog rau kev tsim cov khoom siv hluav taws xob semiconductor.

4. Kev ruaj ntseg tshuaj lom neeg ntau dua: SIC wafers muaj cov tshuaj tiv thaiv corrosion, uas pab txhim kho kev ntseeg tau thiab ua haujlwm ntev ntawm lub cuab yeej.

5. Qhov sib txawv ntawm qhov dav dav: SIC wafers muaj qhov sib txawv ntawm qhov dav dua li silicon, ua rau SIC cov cuab yeej zoo dua thiab ruaj khov ntawm qhov kub thiab txias.

Silicon carbide wafer muaj ntau daim ntawv thov

1.Mechanical teb: txiav cov cuab yeej thiab cov khoom sib tsoo; Hnav-resistant qhov chaw thiab bushings; Industrial valves thiab seals; Bearings thiab pob

2.Electronic fais fab teb: fais fab semiconductor li; High zaus microwave caij; High voltage thiab kub kub fais fab hluav taws xob; Cov khoom siv thermal tswj

3.Chemical kev lag luam: tshuaj reactor thiab khoom siv; Corrosion-resistant kav thiab cia tank; Kev them nyiaj yug tshuaj catalyst

4.Energy sector: roj turbine thiab turbocharger Cheebtsam; Nuclear fais fab core thiab structural Cheebtsam siab kub roj cell Cheebtsam

5.Aerospace: thermal tiv thaiv systems rau missiles thiab chaw tsheb; Dav hlau cav turbine hniav; Advanced composite

6.Lwm qhov chaw: Kub sensors thiab thermopiles; Tuag thiab cov cuab yeej rau sintering txheej txheem; Sib tsoo thiab polishing thiab txiav teb

ZMKJ tuaj yeem muab cov khoom siv zoo ib leeg siv lead ua SiC wafer (Silicon Carbide) rau kev lag luam hluav taws xob thiab optoelectronic. SiC wafer yog cov khoom siv semiconductor tiam tom ntej, nrog cov khoom siv hluav taws xob tshwj xeeb thiab cov khoom siv hluav taws xob zoo heev, piv rau silicon wafer thiab GaAs wafer, SiC wafer yog qhov tsim nyog rau kev kub siab thiab kev siv hluav taws xob siab. SiC wafer tuaj yeem muab rau hauv txoj kab uas hla 2-6 nti, ob qho tib si 4H thiab 6H SiC, N-hom, Nitrogen doped, thiab semi-insulating hom muaj. Thov hu rau peb kom paub ntau ntxiv txog cov khoom.

Peb lub Hoobkas muaj cov cuab yeej tsim khoom siab heev thiab pab pawg ua haujlwm, uas tuaj yeem hloov kho ntau yam tshwj xeeb, tuab thiab cov duab ntawm SiC wafer raws li cov neeg siv khoom tshwj xeeb.

Daim duab qhia ntxaws