SiCOI wafer 4inch 6inch HPSI SiC SiO2 Si subatrate qauv

SiCOI wafer tus qauv

HPB (High-Performance Bonding) BIC (Bonded Integrated Circuit) thiab SOD (Silicon-on-Diamond lossis Silicon-on-Insulator-zoo li thev naus laus zis). Nws suav nrog:

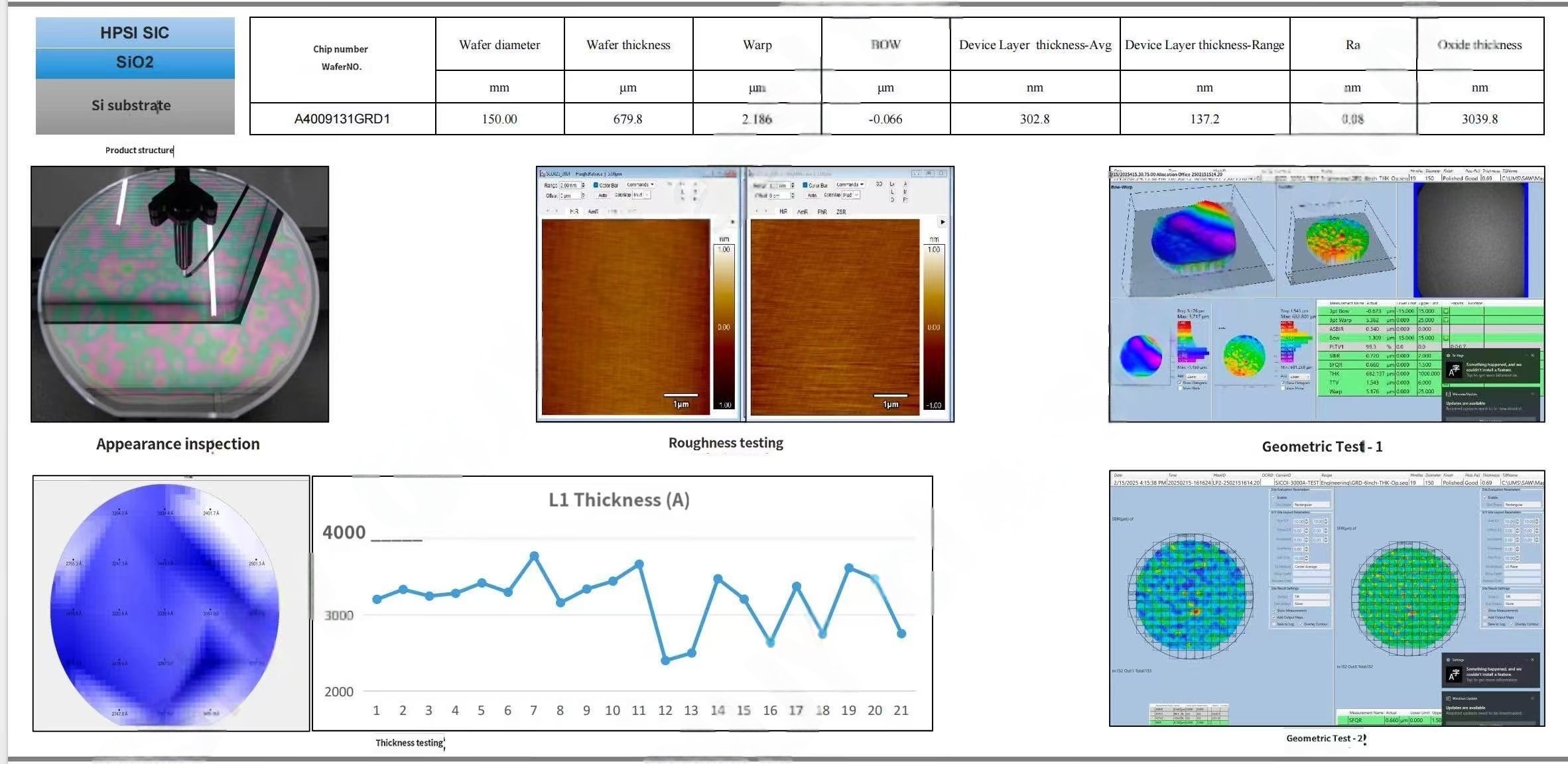

Performance Metrics:

Sau cov kev txwv xws li qhov tseeb, hom kev ua yuam kev (piv txwv li, "Tsis muaj qhov yuam kev," "Nqi nrug"), thiab ntsuas thickness (piv txwv li, "Direct-Layer thickness / kg").

Ib lub rooj nrog tus lej muaj nuj nqis (tejzaum nws yog qhov kev sim lossis cov txheej txheem tsis ua haujlwm) nyob rau hauv nqe lus xws li "ADDR/SYGBDT," "10/0," thiab lwm yam.

Txheej Thickness Cov ntaub ntawv:

Cov ntawv sau rov ua dua uas sau tias "L1 Thickness (A)" rau "L270 Thickness (A)" (zoo li hauv Ångströms, 1 Å = 0.1 nm).

Qhia txog cov txheej txheem ntau txheej nrog cov tuab tuab tswj rau txhua txheej, feem ntau hauv cov khoom siv semiconductor wafers.

SiCOI Wafer Structure

SiCOI (Silicon Carbide ntawm Insulator) yog ib qho tshwj xeeb wafer qauv combining silicon carbide (SiC) nrog ib txheej insulating, zoo ib yam li SOI (Silicon-on-Insulator) tab sis optimized rau high-power / high-temperature daim ntaub ntawv. Cov yam ntxwv tseem ceeb:

Txheej Txheej:

Sab saum toj Txheej: Ib leeg-crystal Silicon Carbide (SiC) rau siab electron txav thiab thermal stability.

faus Insulator: Feem ntau SiO₂ (oxide) lossis pob zeb diamond (hauv SOD) kom txo tau cov kab mob parasitic capacitance thiab txhim kho kev sib cais.

Base Substrate: Silicon lossis polycrystalline SiC rau kev txhawb nqa tshuab

SiCOI wafer cov khoom

Cov khoom hluav taws xob Wide Bandgap (3.2 eV rau 4H-SiC): Ua kom muaj zog tawg siab (> 10 × siab dua silicon).

High Electron Mobility:~ 900 cm²/V·s (4H-SiC) vs. ~ 1,400 cm²/V·s (Si), tab sis zoo dua kev ua haujlwm siab.

Tsawg On-Resistance:SiCOI-raws li transistors (piv txwv li, MOSFETs) pom kev poob qis dua.

Insulation zoo heev:Lub faus oxide (SiO₂) los yog pob zeb diamond txheej txo cov kab mob parasitic capacitance thiab crosstalk.

- Thermal PropertiesHigh Thermal Conductivity: SiC (~ 490 W / m·K rau 4H-SiC) vs Si (~ 150 W / m·K). Pob zeb (yog siv los ua insulator) tuaj yeem tshaj 2,000 W / m·K, txhim kho cov cua sov.

Thermal stability:Ua haujlwm ruaj khov ntawm> 300 ° C (vs. ~ 150 ° C rau silicon).

3. Mechanical & Chemical PropertiesHardness heev (~ 9.5 Mohs): Tiv thaiv hnav, ua SiCOI ruaj khov rau qhov chaw hnyav.

Chemical Inertness:Resistant oxidation thiab corrosion, txawm nyob rau hauv acidic / alkaline tej yam kev mob.

Tsawg Thermal Expansion:Ua tau zoo nrog lwm cov ntaub ntawv kub (piv txwv li, GaN).

4. Cov qauv zoo (vs. Bulk SiC lossis SOI)

Txo Substrate Losses:Insulating txheej tiv thaiv tam sim no ntws mus rau hauv lub substrate.

Txhim kho RF Performance:Cov kab mob qis qis ua rau muaj kev hloov pauv sai dua (pab tau rau 5G / mmWave li).

Flexible Design:Nyias SiC sab saum toj txheej tso cai rau cov cuab yeej ua kom zoo tshaj plaws (piv txwv li, ultra-thin channels hauv transistors).

Sib piv nrog SOI & Bulk SiC

| Khoom | SiCOI | SOI (Si/SiO₂/Si) | Bulk SiC |

| Bandgap | 3.2 eV (SiC) | 1.1 eV (Si) | 3.2 eV (SiC) |

| Thermal conductivity | Siab (SiC + pob zeb diamond) | Tsawg (SiO₂ txwv cov cua sov ntws) | Siab (SiC nkaus xwb) |

| Kev tawg Voltage | Siab heev | Nruab nrab | Siab heev |

| Nqi | Siab dua | qis | Siab tshaj (Ntshiab SiC) |

SiCOI wafer daim ntawv thov

Fais fab Electronics

SiCOI wafers tau siv dav hauv high-voltage thiab high-power semiconductor li xws li MOSFETs, Schottky diodes, thiab fais fab hloov. Qhov dav bandgap thiab siab tawg voltage ntawm SiC ua kom muaj zog hloov pauv nrog txo qhov poob thiab txhim kho kev ua haujlwm thermal.

Xov tooj cua zaus (RF) Devices

Cov txheej insulating nyob rau hauv SiCOI wafers txo cov kab mob parasitic capacitance, ua rau lawv haum rau high-frequency transistors thiab amplifiers siv nyob rau hauv kev sib txuas lus, radar, thiab 5G technologies.

Microelectromechanical Systems (MEMS)

SiCOI wafers muab lub platform muaj zog rau fabricating MEMS sensors thiab actuators uas khiav lag luam ntseeg siab nyob rau hauv hnyav ib puag ncig vim SiC cov tshuaj inertness thiab mechanical zog.

Cov Khoom Siv Hluav Taws Xob Kub Kub

SiCOI tso cai rau cov khoom siv hluav taws xob uas tswj kev ua haujlwm thiab kev ntseeg siab ntawm qhov kub siab, muaj txiaj ntsig rau tsheb, aerospace, thiab kev lag luam kev lag luam uas cov khoom siv silicon ua tsis tau.

Photonic thiab Optoelectronic Devices

Kev sib xyaw ua ke ntawm SiC cov khoom siv kho qhov muag thiab cov txheej txheej insulating pab txhawb kev sib koom ua ke ntawm photonic circuits nrog kev txhim kho thermal tswj.

Radiation-Hardened Electronics

Vim tias muaj hluav taws xob ua tau zoo ntawm SiC, SiCOI wafers yog qhov zoo tshaj plaws rau qhov chaw thiab cov ntawv siv hluav taws xob uas xav tau cov khoom siv uas tiv taus qhov chaw muaj hluav taws xob ntau.

SiCOI wafer's Q&A

Q1: SiCOI wafer yog dab tsi?

A: SiCOI sawv cev rau Silicon Carbide-on-Insulator. Nws yog ib tug semiconductor wafer qauv uas nyias txheej ntawm silicon carbide (SiC) yog sib koom ua ke rau ib txheej insulating (feem ntau silicon dioxide, SiO₂), uas yog txhawb los ntawm silicon substrate. Cov qauv no sib xyaw ua ke SiC cov khoom zoo heev nrog kev sib cais hluav taws xob los ntawm cov insulator.

Q2: Dab tsi yog qhov zoo ntawm SiCOI wafers?

A: Cov txiaj ntsig tseem ceeb suav nrog cov hluav taws xob tawg siab, dav bandgap, zoo thermal conductivity, superior mechanical hardness, thiab txo cov cab capacitance ua tsaug rau txheej insulating. Qhov no ua rau kev txhim kho cov cuab yeej ua haujlwm, kev ua tau zoo, thiab kev ntseeg tau.

Q3: Dab tsi yog daim ntawv thov ntawm SiCOI wafers?

A: Lawv yog siv rau hauv hluav taws xob hluav taws xob, cov khoom siv hluav taws xob siab RF, MEMS sensors, hluav taws xob kub kub, cov khoom siv hluav taws xob, thiab hluav taws xob hluav taws xob.

Daim duab qhia ntxaws