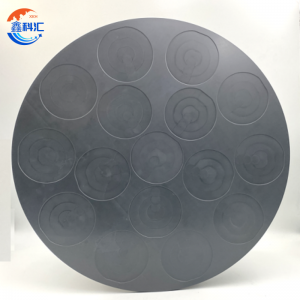

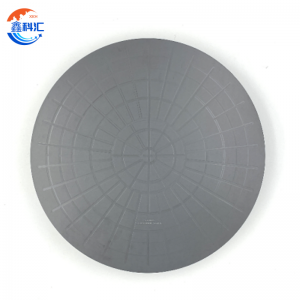

Silicon Carbide Ceramic Tray - Durable, High-Performance Tais rau Thermal and Chemical Applications

Daim duab qhia ntxaws

Khoom Taw Qhia

Silicon carbide (SiC) ceramic tais yog cov khoom siv ua haujlwm siab dav siv nyob rau hauv high-temperature, high-load, thiab chemically hnyav kev lag luam ib puag ncig. Tsim los ntawm cov khoom siv silicon carbide ceramics siab heev, cov tais no yog tsim los xa cov khoom siv zog tshwj xeeb, kev ua haujlwm zoo thermal, thiab zoo heev tiv thaiv thermal shock, oxidation, thiab corrosion. Lawv lub zog muaj zog ua rau lawv tsim nyog rau ntau yam kev lag luam xws li kev tsim khoom semiconductor, kev ua haujlwm photovoltaic, sintering ntawm hmoov metallurgy qhov chaw, thiab lwm yam.

Silicon carbide trays ua cov khoom tseem ceeb los yog kev txhawb nqa thaum lub sij hawm kho cua sov txheej txheem uas qhov tseeb qhov tseeb, kev ua haujlwm ruaj khov, thiab tshuaj tiv thaiv yog qhov tseem ceeb. Piv nrog rau cov khoom siv ceramic ib txwm muaj xws li alumina lossis mullite, SiC cov tais muaj kev ua tau zoo dua, tshwj xeeb tshaj yog nyob rau hauv cov xwm txheej uas muaj kev rov ua dua thermal cycling thiab aggressive atmospheres.

Txheej txheem tsim khoom & Cov khoom sib xyaw

Kev tsim cov khoom siv sic ceramic cuam tshuam yog precision sintering technologies kom ntseeg tau tias siab ntom ntom, cov teeb tsa micrived, thiab kev ua tau zoo ib yam nkaus xwb. Cov kauj ruam dav dav suav nrog:

-

Kev xaiv raw khoom

High-purity silicon carbide hmoov (≥99%) raug xaiv, feem ntau nrog cov particle loj tswj thiab tsawg impurities los lav siab txhua yam thiab thermal zog. -

Txoj kev tsim

Raws li cov kev qhia tshwj xeeb ntawm lub tais, cov txheej txheem sib txawv yog ua haujlwm:-

Txias Isostatic Pressing (CIP) rau high-density, uniform compacts

-

Extrusion los yog plam casting rau complex duab

-

Txhaj tshuaj molding rau meej, cov ncauj lus kom ntxaws geometry

-

-

Cov txheej txheem sintering

Lub cev ntsuab yog sintered ntawm ultra-siab kub, feem ntau nyob rau hauv thaj tsam ntawm 2000 ° C, nyob rau hauv inert los yog lub tshuab nqus tsev cua. Cov txheej txheem sintering muaj xws li:-

Cov tshuaj tiv thaiv Bonded SiC (RB-SiC)

-

Pressureless Sintered SiC (SiC)

-

Recrystallized SiC (RBSiC)

Txhua txoj kev ua rau cov khoom sib txawv me ntsis, xws li porosity, lub zog, thiab thermal conductivity.

-

-

Precision Machining

Tom qab sintering, cov tais yog machined kom ua tau kom nruj me ntsis kam rau ua, du nto tiav, thiab flatness. Kev kho deg xws li lapping, sib tsoo, thiab polishing tuaj yeem siv raws li cov neeg siv khoom xav tau.

Tej kev siv

Silicon carbide ceramic tais yog siv nyob rau hauv ntau yam kev lag luam vim lawv versatility thiab resilience. Cov ntawv thov uas muaj xws li:

-

Kev lag luam semiconductor

SiC cov tais yog siv los ua cov nqa khoom thaum lub sij hawm wafer annealing, diffusion, oxidation, epitaxy, thiab implantation txheej txheem. Lawv qhov ruaj khov ua kom muaj qhov sib txawv ntawm qhov kub thiab txias thiab muaj kev sib kis tsawg. -

Photovoltaic (PV) kev lag luam

Hauv kev tsim hluav taws xob hnub ci, SiC cov tais txhawb nqa silicon ingots lossis wafers thaum kub kub diffusion thiab sintering cov kauj ruam. -

Hmoov Metallurgy thiab Ceramics

Siv los txhawb cov khoom siv thaum sintering ntawm cov hmoov hlau, ceramics, thiab cov ntaub ntawv sib xyaw. -

Iav thiab Display Panels

Siv ua cov tais ci los yog lub platform rau kev tsim cov tsom iav tshwj xeeb, LCD substrates, lossis lwm yam khoom siv kho qhov muag. -

Chemical Processing thiab Thermal Furnaces

Ua haujlwm raws li cov neeg nqa khoom tiv thaiv corrosion hauv cov tshuaj reactors lossis ua cov khoom siv hluav taws xob hauv lub tshuab nqus tsev thiab tswj cov cua sov.

Cov yam ntxwv tseem ceeb

-

✅Tshwj xeeb Thermal Stability

Withstands siv tas li nyob rau hauv qhov kub txog li 1600-2000 ° C yam tsis muaj warping lossis degradation. -

✅Siab Mechanical Strength

Muab lub zog flexural siab (feem ntau> 350 MPa), kom ntseeg tau lub sijhawm ntev txawm tias nyob rau hauv cov xwm txheej siab. -

✅Thermal Shock Resistance

Kev ua tau zoo nyob rau hauv ib puag ncig nrog kev hloov pauv kub ceev, txo qhov kev pheej hmoo ntawm kev tawg. -

✅Corrosion thiab Oxidation Resistance

Chemically ruaj khov nyob rau hauv feem ntau acids, alkalis, thiab oxidizing / txo gases, haum rau hnyav txheej txheem. -

✅Dimensional Accuracy thiab Flatness

Machined rau high precision, kom ntseeg tau tias cov txheej txheem sib xws thiab kev sib raug zoo nrog cov tshuab ua haujlwm. -

✅Ntev Lifespan & Nqi-Efficiency

Kev hloov pauv qis dua thiab txo cov nqi kho mob ua rau nws muaj txiaj ntsig zoo rau lub sijhawm.

Technical Specifications

| Parameter | Tus nqi |

|---|---|

| Khoom siv | Reaction Bonded SiC / Sintered SiC |

| Max. Ua haujlwm kub | 1600-2000 ° C |

| Flexural zog | ≥350 MPa |

| Qhov ntom | ≥3.0g / cm³ |

| Thermal conductivity | 120-180 W/m·K |

| Nto Flatness | ≤ 0.1 hli |

| Thickness | 5-20 hli (Customizable) |

| Qhov ntev | Txheem: 200 × 200 mm, 300 × 300 mm, thiab lwm yam. |

| Nto tiav | Machined, polished (raws li thov) |

Cov lus nug nquag nug (FAQ)

Q1: Puas tuaj yeem siv silicon carbide tais hauv lub tshuab nqus tsev?

A:Yog lawm, SiC cov tais yog qhov zoo tagnrho rau qhov chaw nqus tsev vim lawv qhov qis qis, tshuaj lom neeg ruaj khov, thiab kub-resistant.

Q2: Puas yog cov duab kev cai lossis cov qhov qhib muaj?

A:kiag li. Peb muab cov kev pabcuam customization nrog rau lub tais loj, cov duab, cov yam ntxwv saum npoo (xws li, zawj, qhov), thiab polishing nto kom tau raws li cov neeg siv khoom tshwj xeeb.

Q3: SiC piv nrog alumina lossis quartz tais li cas?

A:SiC muaj zog dua, zoo thermal conductivity, thiab superior tiv thaiv thermal shock thiab tshuaj corrosion. Thaum alumina muaj txiaj ntsig zoo dua, SiC ua tau zoo dua hauv qhov xav tau ib puag ncig.

Q4: Puas muaj tus qauv tuab rau cov tais no?

A:Thickness feem ntau yog nyob rau hauv thaj tsam ntawm 5-20 hli, tab sis peb tuaj yeem kho nws raws li koj daim ntawv thov thiab cov kev cai thauj khoom.

Q5: Lub sij hawm coj mus kuaj rau SiC cov tais yog dab tsi?

A:Lub sij hawm txhuas sib txawv nyob ntawm qhov nyuaj thiab ntau tab sis feem ntau yog li ntawm 2 txog 4 lub lis piam rau kev txiav txim.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.