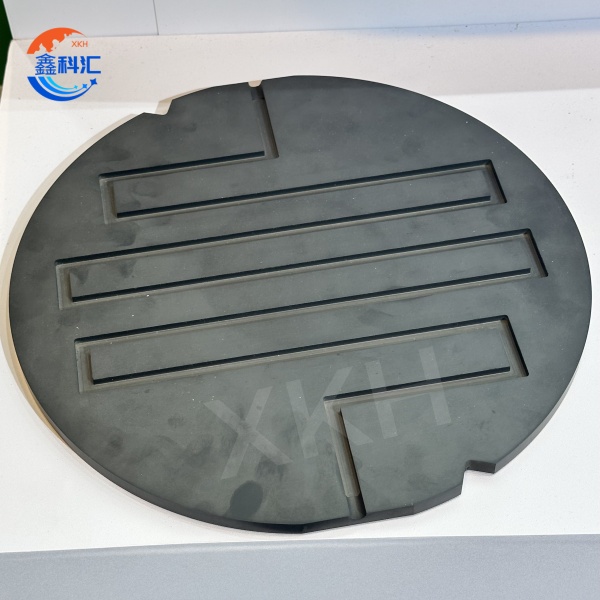

Silicon carbide ceramic tais sucker Silicon carbide ceramic raj muab kub sintering kev cai ua

Cov yam ntxwv tseem ceeb:

1. Silicon carbide ceramic tais

- High hardness thiab hnav tsis kam: lub hardness yog ze rau pob zeb diamond, thiab tuaj yeem tiv taus cov khoom siv hauv kev ua haujlwm ntev ntev.

- High thermal conductivity thiab qis thermal expansion coefficient: ceev kub dissipation thiab seem stability, tsis txhob deformation los ntawm thermal stress.

- High flatness thiab deg tiav: Qhov chaw tiaj tus yog mus txog qib micron, ua kom muaj kev sib cuag tag nrho ntawm wafer thiab disk, txo cov kab mob thiab kev puas tsuaj.

Chemical stability: Muaj zog corrosion kuj, haum rau ntub tu thiab etching txheej txheem nyob rau hauv semiconductor manufacturing.

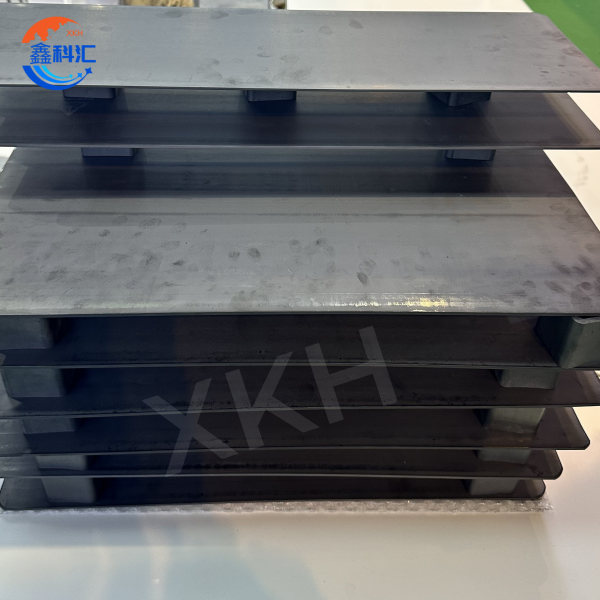

2. Silicon carbide ceramic raj

- Kev kub siab ua haujlwm: Nws tuaj yeem ua haujlwm nyob rau hauv qhov chaw kub siab tshaj 1600 ° C rau lub sijhawm ntev, haum rau cov txheej txheem kub ntawm semiconductor.

Zoo heev corrosion kuj: resistant rau acids, alkalis thiab ntau yam tshuaj solvents, haum rau hnyav txheej txheem ib puag ncig.

- High hardness thiab hnav tsis kam: tiv taus particle yaig thiab mechanical hnav, ncua kev pab cuam lub neej.

- High thermal conductivity thiab qis coefficient ntawm thermal expansion: ceev ceev ntawm tshav kub thiab seem stability, txo deformation los yog tawg los ntawm thermal stress.

Khoom Parameter:

Silicon carbide ceramic tais parameter:

| (Material khoom) | (Unit) | (ssic) | |

| (SiC cov ntsiab lus) | (Wt)% | > 99 | |

| (Average grain size) | micron | 4-10 | |

| (Density) | kg/dm 3 | > 3.14 | |

| (Tshooj porosity) | Vo 1% | <0.5 | |

| (Vickers hardness) | HV 0.5 | GPa | 28 |

| *() Flexural zog * (peb ntsiab lus) | 20ºC tso | MPa | 450 |

| (Compressive zog) | 20ºC tso | MPa | 3900 ib |

| (Elastic Modulus) | 20ºC tso | GPa | 420 |

| (Fracture toughness) | MPa / m '% | 3.5 | |

| (Thermal conductivity) | 20°C kub | W / (m * K) | 160 |

| (Resistivity) | 20°C kub | Aw.cm | 106-108 : kuv |

(Thermal expansion coefficient) | ib (RT**...80ºC) | K-1 * 10-6 | 4.3 |

(Qhov siab tshaj plaws ua haujlwm kub) | oºC ua | 1700 | |

Silicon carbide ceramic raj parameter:

| Cov khoom | Index |

| α-SIB | 99% min |

| Pom tseeb Porosity | 16% max |

| Kev ceev ceev | 2.7g / cm3 min |

| Khoov zog ntawm qhov kub thiab txias | 100 Mpa min |

| Coefficient ntawm Thermal Expansion | K-1 4.7x10 -6 |

| Coefficient ntawm Thermal Conductivity (1400ºC) | 24 W/mk |

| Max. Ua haujlwm kub | 1650ºC |

Cov ntawv thov tseem ceeb:

1. Silicon carbide ceramic phaj

- Wafer txiav thiab polishing: ua haujlwm raws li cov kabmob ua haujlwm kom ntseeg tau siab thiab ruaj khov thaum txiav thiab polishing.

- Cov txheej txheem lithography: Lub wafer tau tsau rau hauv lub tshuab lithography kom ntseeg tau tias qhov chaw siab tshaj thaum raug.

- Tshuaj Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txhuam Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej Txheej

2. Silicon carbide ceramic raj

- Kub kub rauv tube: siv rau cov khoom kub kub xws li diffusion rauv thiab oxidation rauv kom nqa wafers rau cov txheej txheem kub kub.

- CVD / PVD txheej txheem: Raws li cov kabmob hauv cov tshuaj tiv thaiv chamber, resistant rau kub kub thiab corrosive gases.

- Cov khoom siv semiconductor: rau cov khoom siv hluav taws xob, cov kav dej, thiab lwm yam, txhawm rau txhim kho thermal tswj kev ua haujlwm ntawm cov khoom siv.

XKH muaj ntau yam kev pabcuam kev cai rau silicon carbide ceramic tais, suction khob thiab silicon carbide ceramic raj. Silicon carbide ceramic tais thiab suction khob, XKH tuaj yeem kho raws li cov neeg siv khoom xav tau ntawm ntau qhov sib txawv, cov duab thiab qhov roughness, thiab txhawb kev kho tshwj xeeb, txhim khu kev hnav thiab corrosion kuj; Rau silicon carbide ceramic raj, XKH tuaj yeem hloov kho ntau yam ntawm txoj kab uas hla, sab nraud, qhov ntev thiab cov qauv (xws li lub raj zoo li lub raj lossis lub raj ntxeem tau), thiab muab polishing, anti-oxidation txheej thiab lwm yam txheej txheem kho deg. XKH ua kom ntseeg tau tias cov neeg siv khoom tuaj yeem siv tag nrho cov txiaj ntsig ntawm kev ua tau zoo ntawm silicon carbide ceramic khoom kom tau raws li qhov xav tau ntawm high-end manufacturing teb xws li semiconductors, leds thiab photovoltaics.

Daim duab qhia ntxaws