Silicon Carbide SiC Ceramic Fork Caj Npab / Tes rau Cov Txheej Txheem Tseem Ceeb

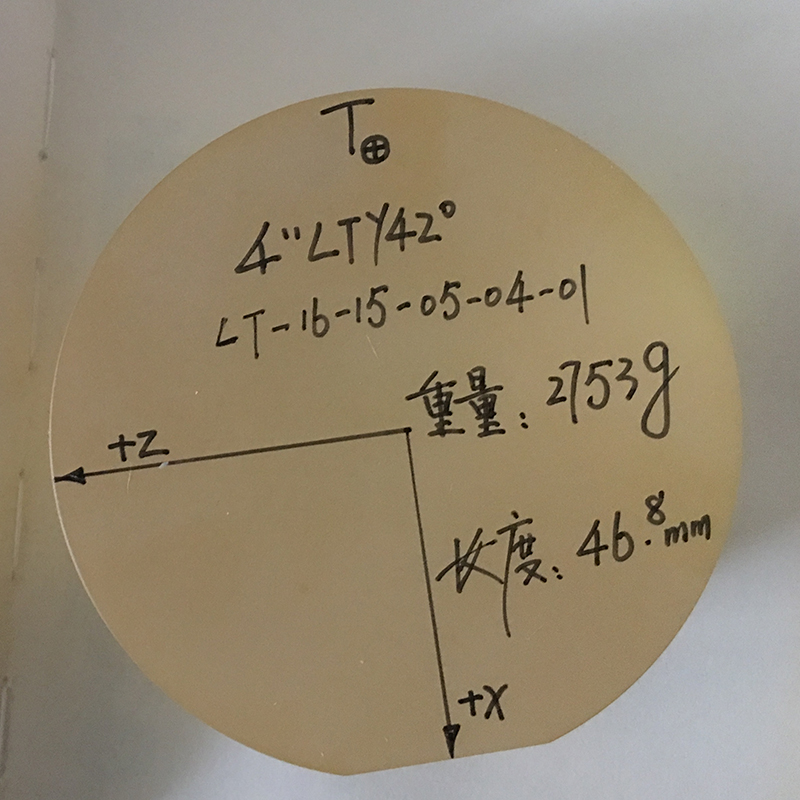

Daim duab qhia ntxaws

Taw qhia ntawm Silicon Carbide Ceramic Fork Arm / Tes

CovSilicon Carbide Ceramic Fork Arm / Tesyog ib qho kev txiav-ntug tsim rau kev lag luam siab heev automation, semiconductor ua, thiab ultra-huv ib puag ncig. Nws qhov tshwj xeeb forked architecture thiab ultra-pav ca ceramic nto ua rau nws zoo tagnrho rau kev tuav cov substrates, suav nrog silicon wafers, iav panels, thiab cov khoom siv kho qhov muag. Engineered nrog precision thiab tsim los ntawm ultra-ntshiab silicon carbide, lubSilicon Carbide Ceramic Fork Arm / Tesmuab cov khoom siv tsis sib haum xeeb, kev ntseeg siab ntawm thermal, thiab kev tswj kev sib kis.

Tsis zoo li cov pa hlau lossis yas caj npab, lubSilicon Carbide Ceramic Fork Arm / Tesmuab kev ua haujlwm ruaj khov hauv huab cua kub, tshuaj lom neeg, thiab lub tshuab nqus tsev. Txawm hais tias ua haujlwm hauv Chav Kawm 1 huv lossis hauv lub tshuab nqus tsev plasma, cov khoom no ua kom muaj kev nyab xeeb, ua haujlwm tau zoo, thiab tsis muaj cov khoom seem ntawm cov khoom muaj nqis.

Nrog cov qauv tsim rau cov caj npab robotic, wafer handlers, thiab automated hloov cuab yeej, lubSilicon Carbide Ceramic Fork Arm / Tesyog kev txawj ntse txawj tej yam ntxiv rau tej high-precision system.

Kev tsim cov txheej txheem ntawm Silicon Carbide Ceramic Fork Arm / Tes

Crafting ib tug high-kev ua tau zooSilicon Carbide Ceramic Fork Arm / Tessuav nrog kev tswj xyuas nruj heev ntawm ceramic engineering workflow uas ua kom rov ua tau dua, kev ntseeg tau, thiab qis qis qis qis.

1. Material Engineering

Tsuas yog ultra-high-purity silicon carbide hmoov yog siv nyob rau hauv fabrication ntawm lubSilicon Carbide Ceramic Fork Arm / Tes, kom ntseeg tau tias tsis muaj ionic paug thiab lub zog loj. Cov hmoov yog precisely blended nrog sintering additives thiab binders kom ua tau zoo densification.

2. Kev tsim cov qauv hauv paus

Lub hauv paus geometry ntawm lubdiav npab / tesyog tsim los siv txias isostatic nias los yog txhaj tshuaj molding, uas ua kom muaj kev nyab xeeb siab ntsuab thiab tsis sib xws kev ntxhov siab. U-shape configuration yog optimized rau nruj-rau-qhov hnyav piv thiab dynamic teb.

3. Sintering txheej txheem

Lub cev ntsuab ntawm lubSilicon Carbide Ceramic Fork Arm / Tesyog sintered nyob rau hauv high-kub, inert roj rauv ntawm tshaj 2000 ° C. Cov kauj ruam no ua kom ze ze-theoretical tuab, tsim ib qho kev tiv thaiv uas tiv taus kev tawg, kev sib txawv, thiab kev sib txawv hauv ntiaj teb thermal loads.

4. Precision Sib tsoo thiab Machining

Advanced CNC pob zeb diamond tooling yog siv los tsim qhov kawg qhov ntev ntawm lubSilicon Carbide Ceramic Fork Arm / Tes. Tight tolerances (± 0.01 mm) thiab daim iav-theem deg tiav txo qhov tso tawm thiab cov neeg kho tshuab kev ntxhov siab.

5. Kev kho qhov chaw saum npoo thiab ntxuav

Qhov kawg nto xov muaj xws li tshuaj polishing thiab ultrasonic tu los npaj covdiav npab / tesrau kev sib koom ua ke ncaj qha hauv ultra-huv tshuab. Cov txheej txheej xaiv tau (CVD-SiC, cov khaubncaws sab nraud povtseg) kuj muaj.

Cov txheej txheem meticulous no lav tias txhua tusSilicon Carbide Ceramic Fork Arm / Tesua tau raws li cov qauv kev lag luam nruj tshaj plaws, suav nrog SEMI thiab ISO cov cai huv huv.

Paramete ntawm Silicon Carbide Ceramic Fork Arm / Tes

| Yam khoom | Kev Xeem | Cov ntaub ntawv | Chav tsev |

| Cov ntsiab lus ntawm Silicon Carbide | / | > 99.5 | % |

| Nruab Nrab Loj Loj | / | 4-10 | micron |

| Qhov ntom | / | > 3.14 | g/cm3 |

| Pom tseeb Porosity | / | <0.5 | Vol % |

| Vickers Hardness | HV 0.5 | 2800 | Kg / hli 2 |

| Modulus Ntawm Repture (3 Points) | Test bar loj: 3 x 4 x 40 mm | 450 | MPa |

| Compression zog | 20 ° C | 3900 ib | MPa |

| Modulus ntawm Elasticity | 20 ° C | 420 | GPa |

| Fracture Toughness | / | 3.5 | MPa/m1/2 |

| Thermal conductivity | 20 ° C | 160 | W / (mK) |

| Hluav taws xob Resistivity | 20 ° C | 106-108 | Ω cm |

| Coefficient ntawm Thermal Expansion | 20 ° C-800 ° C | 4.3 | K-110-6 |

| Max. Daim ntawv thov kub | Oxide Atmosphere | 1600 | °C |

| Max. Daim ntawv thov kub | Inert Atmosphere | Xyoo 1950 | °C |

Daim ntawv thov ntawm Silicon Carbide Ceramic Fork Arm / Tes

CovSilicon Carbide Ceramic Fork Arm / Tesyog tsim los siv rau hauv high-precision, high-risk, thiab contamination-sensitive daim ntaub ntawv. Nws ua kom txhim khu kev qha tuav, hloov mus, lossis kev txhawb nqa ntawm cov khoom tseem ceeb uas tsis muaj kev cuam tshuam.

➤ Kev Lag Luam Semiconductor

-

Siv raws li rab rawg neeg hlau hauv pem hauv ntej-kawg wafer hloov chaw thiab FOUP chaw nres tsheb.

-

Muab tso rau hauv lub tshuab nqus tsev rau plasma etching thiab PVD / CVD txheej txheem.

-

Kev ua haujlwm raws li tus nqa caj npab hauv metrology thiab wafer alignment cov cuab yeej.

CovSilicon Carbide Ceramic Fork Arm / Testshem tawm electrostatic paug (ESD) txaus ntshai, txhawb nqa qhov ntev precision, thiab tiv thaiv cov ntshav plasma corrosion.

➤ Photonics thiab Optics

-

Txhawb nqa cov lo ntsiab muag muag, laser muaju, thiab sensors thaum tsim los yog tshuaj xyuas.

Nws lub siab tawv tiv thaiv kev vibration, thaum lub cev ceramic tiv thaiv kev sib kis ntawm qhov chaw kho qhov muag.

➤ Zaub thiab Vaj Huam Sib Luag Ntau Lawm

-

Kov nyias iav, OLED modules, thiab LCD substrates thaum thauj lossis tshuaj xyuas.

Lub tiaj thiab chemically inertSilicon Carbide Ceramic Fork Arm / Testiv thaiv khawb los yog tshuaj etching.

➤ Aerospace thiab Scientific Instruments

-

Siv nyob rau hauv satellite optics sib dhos, lub tshuab nqus tsev neeg hlau, thiab synchrotron beamline teeb.

Ua tsis tau zoo nyob rau hauv chav tsev huv si thiab cov chaw muaj hluav taws xob zoo.

Nyob rau hauv txhua qhov chaw, lubSilicon Carbide Ceramic Fork Arm / Testxhim khu kev ua haujlwm ntawm lub cev, txo qhov tsis ua haujlwm, thiab txo qis sijhawm.

FAQ - Cov lus nug nquag nug ntawm Silicon Carbide Ceramic Fork Arm / Tes

Q1: Dab tsi ua rau Silicon Carbide Ceramic Fork Arm / Tes zoo dua li lwm cov hlau?

CovSilicon Carbide Ceramic Fork Arm / Tesmuaj superior hardness, tsawg ntom, zoo tshuaj tiv thaiv, thiab ho thermal expansion ntau dua li hlau. Nws tseem yog chav huv huv-tshaj thiab tsis muaj corrosion los yog particle tiam.

Q2: Kuv puas tuaj yeem thov kev cai qhov ntev rau kuv Silicon Carbide Ceramic Fork Arm / Tes?

Yog lawm. Peb muab tag nrho customization, nrog rau rab rawg dav, thickness, mounting qhov, cutouts, thiab nto kho. Seb rau 6 ", 8", lossis 12 "wafers, kojdiav npab / testuaj yeem kho kom haum.

Q3: Ntev npaum li cas Silicon Carbide Ceramic Fork Arm / Tes nyob hauv qab ntshav lossis lub tshuab nqus tsev?

Ua tsaug rau cov khoom siv high-density SiC thiab inert xwm, lubdiav npab / testseem ua haujlwm txawm tias tom qab ntau txhiab tus txheej txheem. Nws qhia tau hais tias hnav tsawg heev hauv cov ntshav plasma lossis lub tshuab nqus tsev kub.

Q4: Cov khoom puas tsim nyog rau ISO Class 1 cleanrooms?

kiag li. CovSilicon Carbide Ceramic Fork Arm / Tesyog tsim thiab ntim rau hauv cov chaw huv huv uas tau lees paub, nrog cov qib particle zoo hauv qab ISO Class 1 qhov yuav tsum tau ua.

Q5: Dab tsi yog qhov siab tshaj plaws ua haujlwm kub rau lub diav rawg / tes?

CovSilicon Carbide Ceramic Fork Arm / Testuaj yeem ua haujlwm tsis tu ncua ntawm mus txog 1500 ° C, ua rau nws tsim nyog rau kev siv ncaj qha rau hauv cov txheej txheem kub kub thiab lub tshuab nqus tsev thermal.

Cov FAQs no muaj kev cuam tshuam txog kev txhawj xeeb tshaj plaws los ntawm engineers, lab tus thawj coj, thiab cov neeg koom ua ke siv covSilicon Carbide Ceramic Fork Arm / Tes.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.