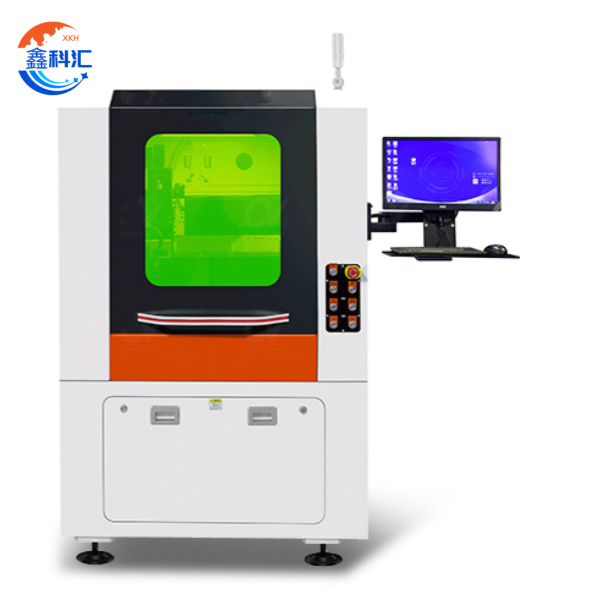

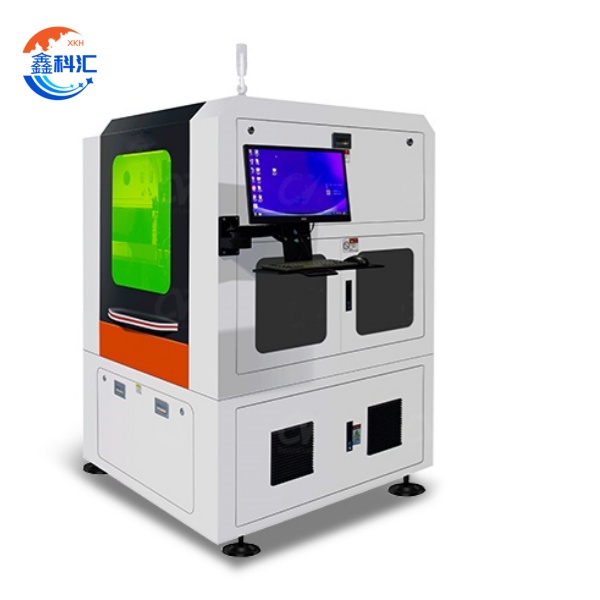

Lub rooj me me laser xuas nrig ntaus tshuab 1000W-6000W yam tsawg kawg nkaus aperture 0.1MM tuaj yeem siv rau cov khoom siv hlau iav ceramic

Cov ntaub ntawv siv tau

1. Cov ntaub ntawv hlau: xws li txhuas, tooj liab, titanium alloy, stainless hlau, thiab lwm yam.

2. Cov ntaub ntawv tsis yog xim hlau: xws li yas (xws li polyethylene PE, polypropylene PP, polyester PET thiab lwm yam yas zaj duab xis), iav (xws li iav zoo tib yam, iav tshwj xeeb xws li ultra-dawb iav, K9 iav, siab borosilicate iav, quartz iav, thiab lwm yam., tab sis tempered iav vim nws cov khoom tshwj xeeb ntawm lub cev), cov ntaub ntawv zoo li ceramics tsis yog li ntawd, tsis tsim nyog rau cov ntaub ntawv.

3. Cov khoom siv sib xyaw: muaj ob lossis ntau dua cov ntaub ntawv uas muaj cov khoom sib txawv los ntawm kev siv lub cev lossis tshuaj lom neeg, nrog rau cov khoom zoo heev.

4.Special cov ntaub ntawv: nyob rau hauv tej qhov chaw, laser xuas nrig ntaus tshuab kuj siv tau los ua tej yam khoom tshwj xeeb.

Specification tsis muaj

| Lub npe | Cov ntaub ntawv |

| Laser zog: | 1000W-6000W |

| Txiav precision: | ± 0.03 hli |

| Yam tsawg kawg nkaus-tus nqi aperture: | 0.1 hli |

| Length ntawm txiav: | 650mm × 800 hli |

| Positional raug: | ≤ ± 0.008MM |

| Rov ua qhov tseeb: | 0.008mm ib |

| Txiav Gas: | Cua |

| Cov qauv ruaj khov: | Pneumatic ntug clamping, kev txhawb nqa fixture |

| Tsav system: | Sib nqus suspension linear motor |

| Txiav thickness | 0.01MM-3MM |

Technical zoo

1.Efficient drilling: Kev siv lub zog loj laser beam rau kev ua haujlwm tsis sib cuag, nrawm, 1 thib ob kom ua tiav cov txheej txheem me me.

2.High precision: Los ntawm kev tswj hwm lub zog, mem tes zaus thiab tsom txoj haujlwm ntawm lub laser, kev ua haujlwm drilling nrog micron precision tuaj yeem ua tiav.

3. Muaj feem xyuam: tuaj yeem ua tau ntau yam nkig, nyuaj rau kev ua haujlwm thiab cov ntaub ntawv tshwj xeeb, xws li yas, roj hmab, hlau (stainless steel, aluminium, tooj liab, titanium alloy, thiab lwm yam), iav, ceramics thiab lwm yam.

4. Kev ua haujlwm ntse: Lub tshuab laser xuas nrig ntaus tau nruab nrog cov lej tswj hwm qib siab, uas yog qhov ntse heev thiab yooj yim rau kev koom ua ke nrog lub khoos phis tawj pab tsim thiab khoos phis tawj pabcuam kev tsim khoom kom paub txog kev ua haujlwm sai thiab kev ua kom zoo ntawm txoj kev nyuaj thiab kev ua haujlwm.

Cov xwm txheej ua haujlwm

1.Diversity: tuaj yeem ua tau ntau yam kev ua haujlwm ntawm qhov nyuaj, xws li lub qhov puag ncig, lub qhov square, daim duab peb sab qhov thiab lwm qhov tshwj xeeb zoo li lub qhov.

2.High zoo: Lub qhov zoo yog qhov siab, lub ntug yog du, tsis muaj kev ntxhib los mos, thiab deformation me me.

3.Automation: Nws tuaj yeem ua tiav cov micro-qhov ua tiav nrog tib lub aperture loj thiab cov khoom faib tawm ib zaug, thiab txhawb pab pawg ua qhov tsis muaj kev cuam tshuam.

Khoom nta

■ Cov khoom siv me me, los daws qhov teeb meem ntawm qhov chaw nqaim.

■ High precision, qhov siab tshaj plaws tuaj yeem ncav cuag 0.005mm.

■ Cov cuab yeej siv tau yooj yim thiab siv tau yooj yim.

■ Lub teeb ci tuaj yeem hloov tau raws li cov khoom sib txawv, thiab kev sib haum xeeb muaj zog dua.

■ Cov cheeb tsam me me thaum tshav kub kub, tsis muaj oxidation nyob ib ncig ntawm lub qhov.

Daim ntawv thov teb

1. Electronics kev lag luam

●Printed Circuit Board (PCB) xuas nrig ntaus:

Microhole machining: Siv rau machining microholes nrog lub cheeb ntawm tsawg dua 0.1 hli ntawm PCBS kom tau raws li qhov xav tau ntawm high-density interconnect (HDI) boards.

Qhov muag tsis pom kev thiab faus qhov: Machining qhov muag tsis pom thiab faus qhov hauv ntau txheej PCBS los txhim kho kev ua haujlwm thiab kev sib koom ua ke ntawm pawg thawj coj saib.

● Semiconductor ntim:

Lead thav duab drilling: Precision qhov yog machined nyob rau hauv lub semiconductor txhuas ncej rau txuas lub nti mus rau sab nraud Circuit Court.

Kev pab txiav wafer: Punch qhov hauv lub wafer los pab hauv kev txiav thiab ntim tom ntej.

2. Precision machinery

●Micro qhov chaw ua:

Precision iav drilling: Machining high-precision qhov ntawm micro iav rau precision kis tshuab.

Sensor Cheebtsam drilling: Machining microholes ntawm lub sensor Cheebtsam los txhim kho lub rhiab heev thiab teb ceev ntawm lub sensor.

● Pwm Manufacturing:

Pwm txias qhov: Machining txias qhov ntawm txhaj tshuaj pwm los yog tuag casting pwm kom optimize lub tshav kub dissipation kev ua tau zoo ntawm pwm.

Vent processing: Machining me me vents ntawm pwm kom txo cov kev ua tsis xws luag.

3. Cov khoom siv kho mob

● Cov cuab yeej phais mob tsawg kawg nkaus:

Catheter perforation: Microholes yog ua tiav nyob rau hauv minimally invasive surgical catheters rau kev xa tshuaj los yog kua dej.

Endoscope Cheebtsam: Precision qhov yog machined nyob rau hauv lub lens los yog lub taub hau ntawm lub endoscope los txhim kho lub functionality ntawm lub ntsuas.

●Drug Delivery System:

Microneedle array drilling: Machining microholes ntawm cov tshuaj thaj chaw lossis microneedle array los tswj cov tshuaj tso tawm.

Biochip drilling: Microholes tau ua tiav ntawm biochips rau kab lis kev cai ntawm tes lossis kev tshawb pom.

4. Cov khoom siv kho qhov muag

● Fiber optic connector:

Kho qhov muag fiber qhov kawg qhov drilling: Machining microholes ntawm lub ntsej muag kawg ntawm optical connector los txhim kho qhov muag teeb liab kis tau tus mob.

Fiber array machining: Machining high-precision qhov ntawm lub phaj fiber ntau rau kev sib txuas lus kho qhov muag.

● Optical filter:

Filter drilling: Machining microholes ntawm lub qhov muag lim kom ua tiav cov kev xaiv ntawm cov wavelengths tshwj xeeb.

Diffractive element machining: Machining microholes ntawm diffractive optical ntsiab rau laser beam splitting los yog shaping.

5. Kev tsim tsheb

● Roj txhaj tshuaj system:

Txhaj tshuaj nozzle xuas nrig ntaus: Ua cov micro-qhov ntawm qhov txhaj tshuaj nozzle kom ua kom zoo dua cov roj atomization thiab txhim kho kev sib txuas ua haujlwm.

●Sensor manufacturing:

Siab sensor drilling: Machining microholes ntawm lub siab sensor diaphragm los txhim kho qhov rhiab heev thiab raug ntawm lub sensor.

● Lub zog roj teeb:

Roj teeb ncej nti drilling: Machining microholes ntawm lithium roj teeb ncej chips los txhim kho electrolyte infiltration thiab ion thauj.

XKH muaj ntau yam kev pabcuam ib-nres rau lub rooj me me laser perforators, suav nrog tab sis tsis txwv rau: Kev tshaj lij kev muag khoom, kev tsim qauv tsim, cov khoom siv zoo, kev teeb tsa zoo thiab kev ua haujlwm, kev qhia ua haujlwm ntxaws, kom ntseeg tau tias cov neeg siv khoom tau txais txiaj ntsig zoo tshaj plaws, raug thiab tsis muaj kev pabcuam hauv cov txheej txheem xuas nrig ntaus.

Daim duab qhia ntxaws