Nto ua txoj kev ntawm titanium-doped sapphire siv lead ua laser rods

Taw qhia ntawm Ti: sapphire / ruby

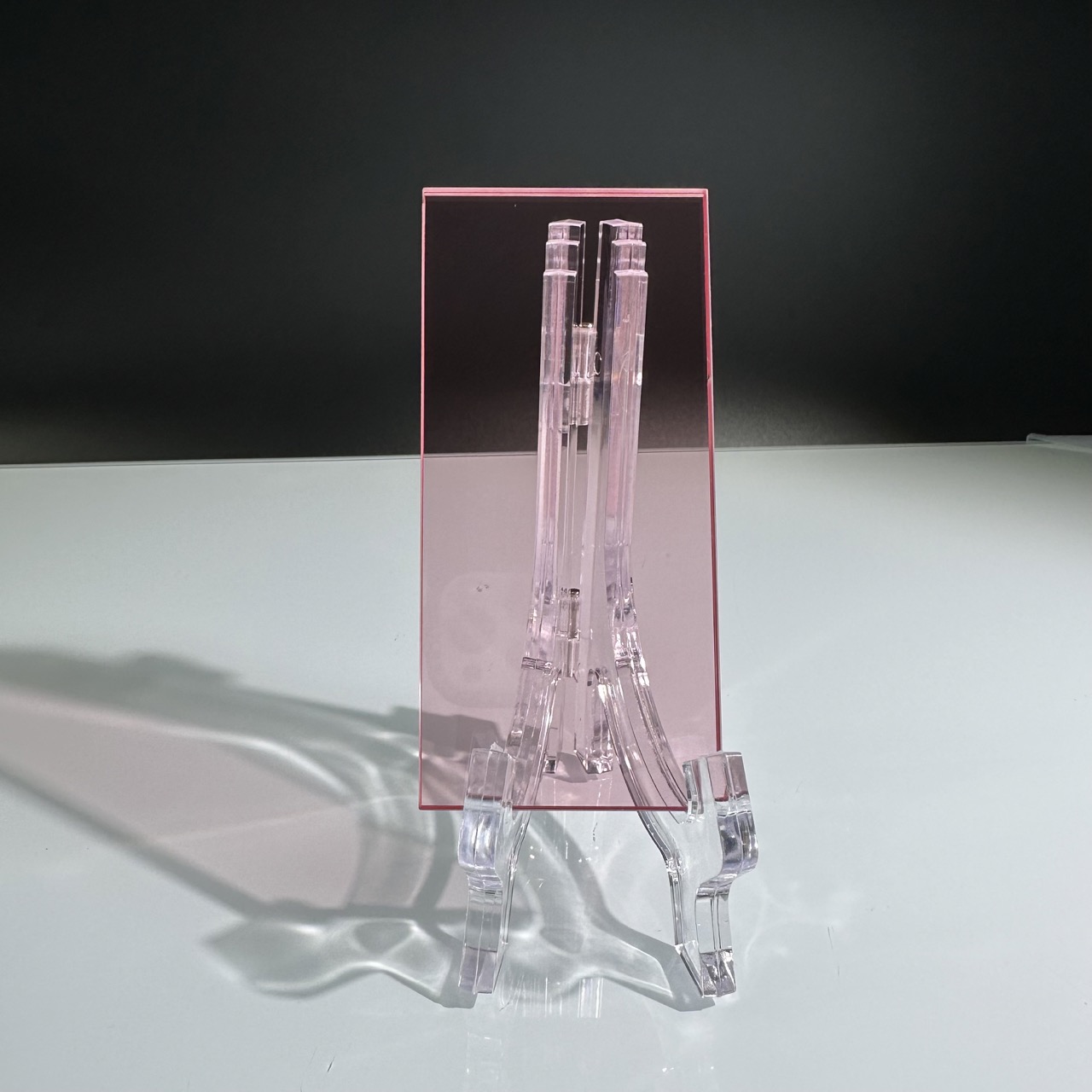

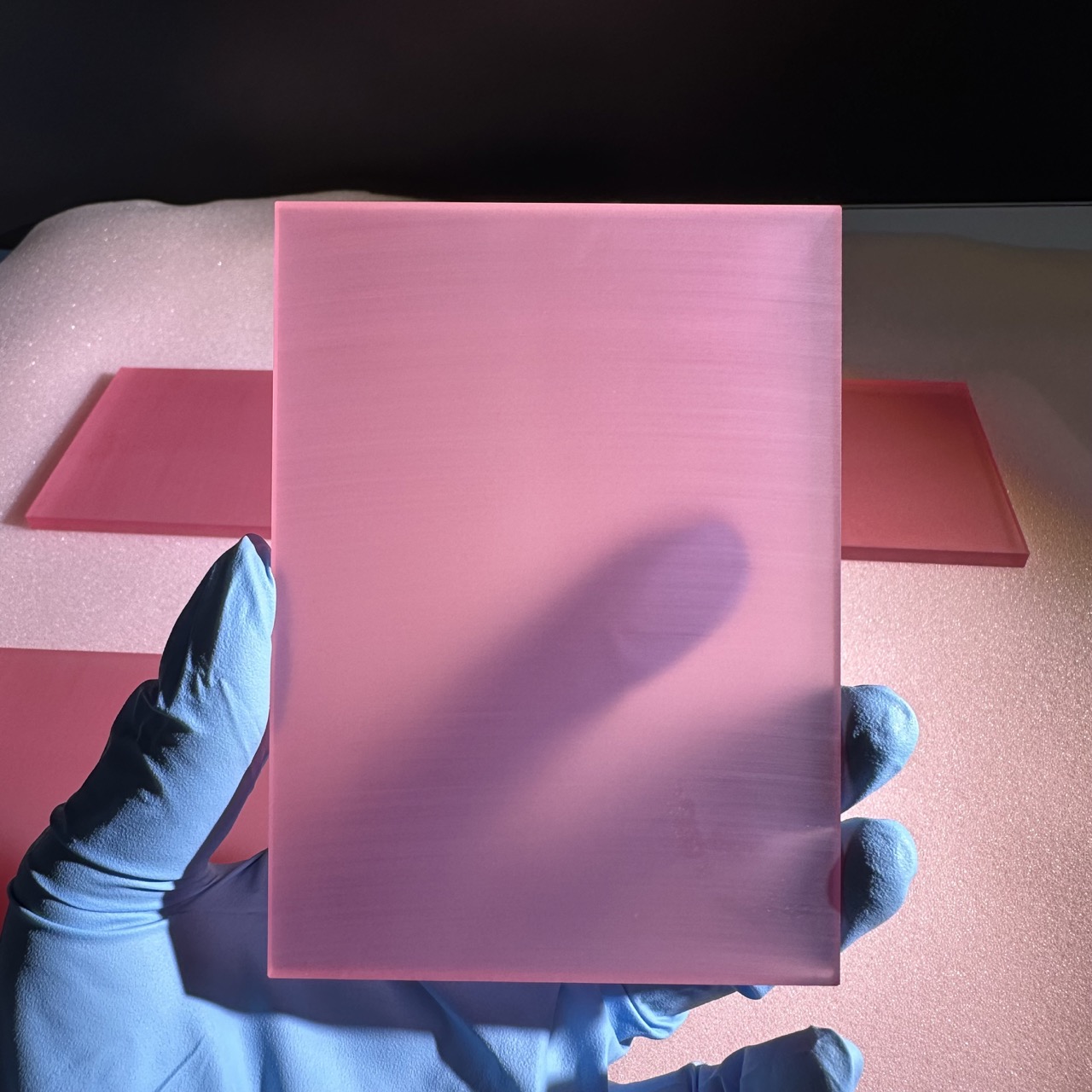

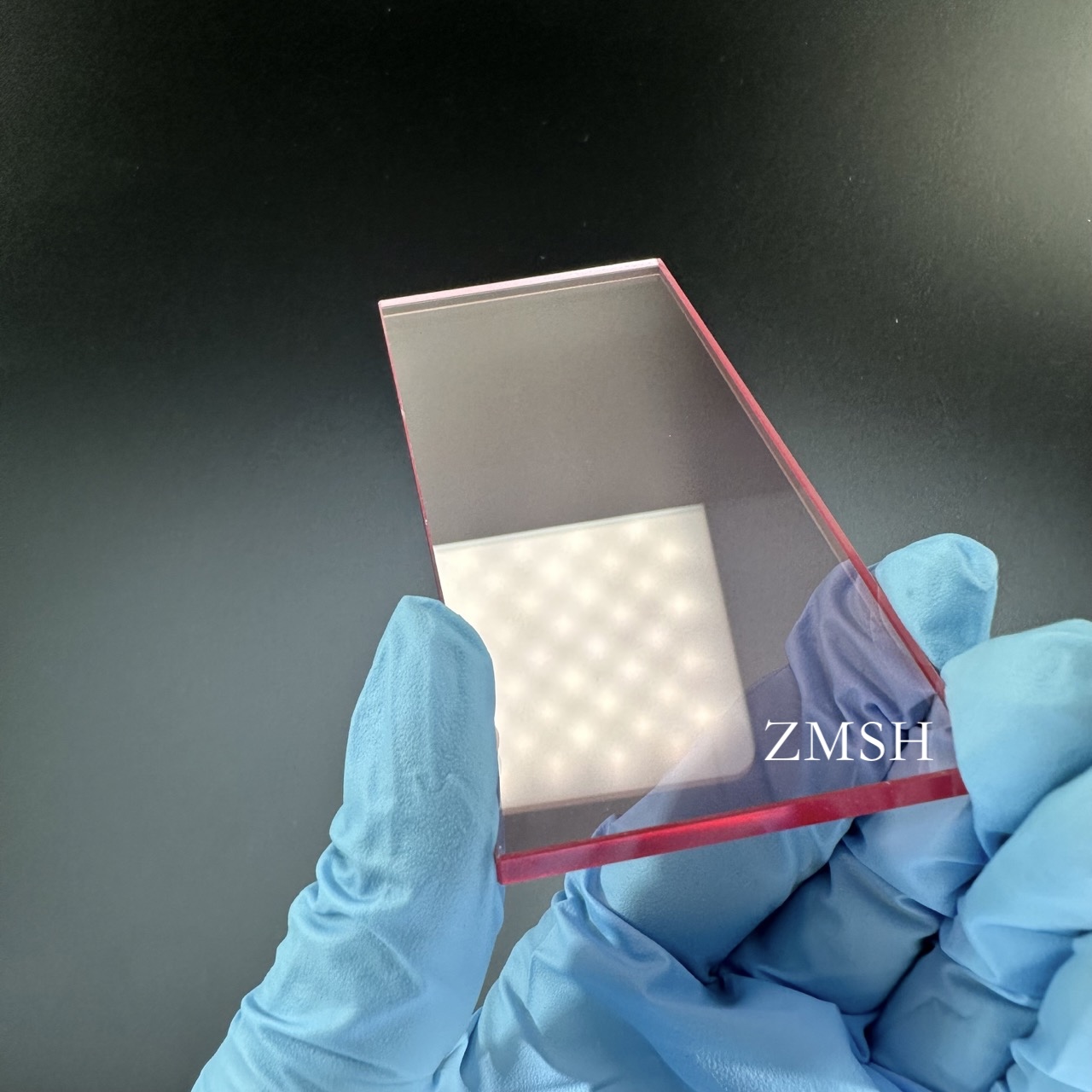

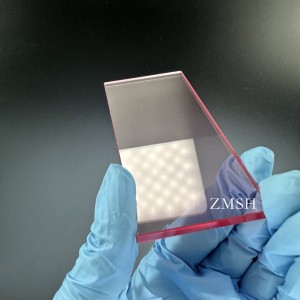

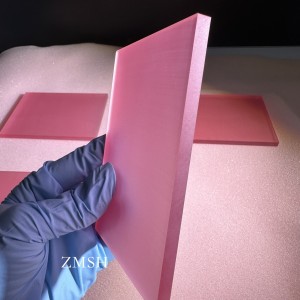

Titanium gemstone crystals Ti: Al2O3 (doping concentration 0.35 wt% Ti2O3), cov siv lead ua blanks uas yog raws li cov txheej txheem ntws daim duab ntawm cov txheej txheem saum npoo ntawm titanium gemstone siv lead ua laser pas nrig ntawm qhov tam sim no invention yog qhia nyob rau hauv daim duab 1. Cov kev npaj cov kauj ruam ntawm lub nto txheej txheem ntawm lub titanium siv lead ua rod yog raws li nram no.

<1> Orientation txiav: titanium gemstone siv lead ua yog thawj taw qhia, thiab tom qab ntawd txiav mus rau hauv tetragonal kem-zoo li tus dawb paug los ntawm kev tawm ntawm kev ua haujlwm ntawm kwv yees li 0.4 mus rau 0.6 hli raws li qhov loj ntawm qhov ua tiav laser pas nrig.

<2>Kem ntxhib thiab zoo sib tsoo: Cov kem dawb yog hauv av rau hauv tetragonal lossis cylindrical cross-section nrog 120 ~ 180# silicon carbide lossis boron carbide abrasives ntawm lub tshuab sib tsoo ntxhib, nrog lub taper thiab tawm-ntawm-roundness yuam kev ntawm ± 0.01mm.

<3> Xaus ntsej muag ua tiav: titanium gemstone laser bar ob lub ntsej muag kawg ua tiav nrog W40, W20, W10 boron carbide sib tsoo lub ntsej muag kawg ntawm cov hlau disc. Hauv kev sib tsoo, kev saib xyuas yuav tsum tau them rau kev ntsuas qhov ntsug ntawm lub ntsej muag kawg.

<4> Tshuaj-mechanical polishing: tshuaj-mechanical polishing yog cov txheej txheem ntawm polishing crystals ntawm polishing ncoo nrog tee ntawm pre-formulated tshuaj etching tov. Polishing workpiece thiab polishing ncoo rau cov txheeb ze thiab kev sib txhuam, thaum nyob rau hauv kev tshawb fawb slurry muaj tshuaj etching tus neeg saib xyuas (hu ua polishing kua) kom tiav polishing nrog kev pab los ntawm.

<5> Acid etching: Cov titanium gemstone pas nrig tom qab polishing raws li tau piav qhia saum toj no yog muab tso rau hauv ib qho sib xyaw ntawm H2SO4: H3PO4 = 3: 1 (v / v), ntawm qhov kub ntawm 100-400 ° C, thiab acid-etched rau 5-30 feeb. Lub hom phiaj yog tshem tawm cov txheej txheem polishing ntawm qhov chaw ntawm lub laser bar uas tsim los ntawm cov neeg kho tshuab sub-nto puas tsuaj, thiab tshem tawm ntau yam staining, thiaj li tau txais cov qib atomic ntawm du thiab tiaj tus, lattice kev ncaj ncees ntawm qhov huv si.

<6> Kev Kho Hniav Hniav: Txhawm rau txhawm rau tshem tawm qhov kev ntxhov siab thiab khawb qhov tsim los ntawm cov txheej txheem ua ntej thiab tau txais ib qho chaw tiaj tus ntawm qib atomic, titanium gemstone pas nrig tom qab cov kua qaub etching tau muab yaug nrog dej deionised rau 5 feeb, thiab titanium gemstone pas nrig ntawm 0 ° C ntawm 1 0 ° C. ntawm 1 mus rau 3 teev nyob rau hauv ib qho chaw hydrogen, thiab raug kev kho cua sov saum npoo.

Daim duab qhia ntxaws