TGV iav substrates 12inch wafer iav punching

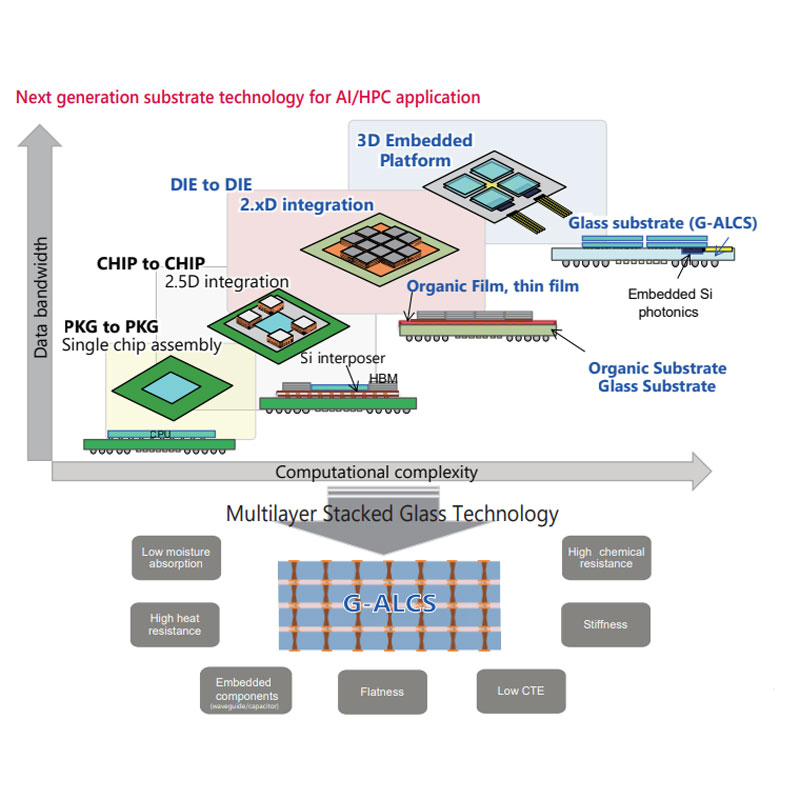

Cov iav substrates ua tau zoo dua ntawm cov khoom siv thermal, lub cev ruaj khov, thiab muaj cua sov ntau dua thiab tsis tshua muaj teeb meem rau warping lossis deformation vim qhov kub thiab txias;

Tsis tas li ntawd, cov khoom siv hluav taws xob tshwj xeeb ntawm cov iav tub ntxhais tso cai rau qis dielectric poob, tso cai kom pom tseeb dua thiab lub zog xa mus. Yog li ntawd, lub zog poob thaum lub teeb liab kis tau tus mob yog txo thiab tag nrho efficiency ntawm lub nti yog lawm boosted. Lub thickness ntawm cov iav core substrate tuaj yeem raug txo los ntawm ib nrab piv rau ABF yas, thiab cov thinning txhim kho cov teeb liab kis ceev thiab lub zog ua haujlwm.

Qhov txheej txheem ntawm TGV:

Laser induced etching txoj kev yog siv los induce nruam denaturation cheeb tsam los ntawm pulsed laser, thiab ces lub laser kho iav yog muab tso rau hauv hydrofluoric acid tov rau etching. Qhov etching tus nqi ntawm denaturation cheeb tsam iav hauv hydrofluoric acid yog sai dua li cov iav undenaturated los ntawm qhov.

TGV sau:

Ua ntej, TGV qhov muag tsis pom qhov yog ua. Qhov thib ob, cov noob txheej tau muab tso rau hauv TGV qhov muag tsis pom los ntawm lub cev vapor deposition (PVD). Thib peb, hauv qab-up electroplating ua tiav seamless filling ntawm TGV; Thaum kawg, los ntawm kev sib tsoo ib ntus, rov qab sib tsoo, tshuaj lom neeg polishing (CMP) tooj liab raug, unbonding, tsim TGV hlau-filled hloov phaj.

Daim duab qhia ntxaws