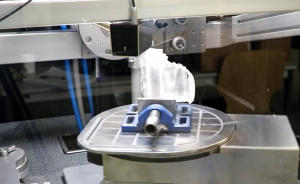

Wafer Orientation System rau Crystal Orientation Measurement

Khoom Taw Qhia

Wafer orientation instruments yog cov cuab yeej precision raws li X-ray diffraction (XRD) cov hauv paus ntsiab lus, feem ntau yog siv hauv kev tsim khoom semiconductor, cov khoom siv kho qhov muag, ceramics, thiab lwm yam khoom siv crystalline industries.

Cov cuab yeej no txiav txim siab siv lead ua lattice orientation thiab qhia meej txiav lossis polishing txheej txheem. Cov yam ntxwv tseem ceeb muaj xws li:

- High-precision ntsuas:Muaj peev xwm daws tau cov dav hlau crystallographic nrog angular kev daws teeb meem mus rau 0.001 ° .

- Cov qauv loj compatibility:Txhawb nqa wafers mus txog 450 mm inch thiab hnyav 30 kg, haum rau cov ntaub ntawv xws li silicon carbide (SiC), sapphire, thiab silicon (Si).

- Modular tsim:Expandable functionalities muaj xws li rocking nkhaus tsom, 3D nto defect mapping, thiab stacking pab kiag li lawm rau ntau tus qauv ua.

Ntsiab Technical Parameters

| Qeb Parameter | Yam Khoom Muaj nqis/Configuration |

| X-ray Source | Cu-Kα (0.4 × 1 hli focal chaw), 30 kV accelerating voltage, 0-5 mA adjustable raj tam sim no |

| Angular Range | θ: -10 ° rau + 50 °; 2θ: -10 ° rau + 100 ° |

| Qhov tseeb | Tilt lub kaum sab xis daws teeb meem: 0.001 °, deg defect detection: ± 30 arcseconds (pob zeb nkhaus) |

| Scanning Ceev | Omega scan ua tiav kev taw qhia lattice hauv 5 vib nas this; Theta scan siv sijhawm ~ 1 feeb |

| Qauv Theem | V-groove, pneumatic suction, ntau lub kaum sab xis tig, sib xws nrog 2-8-nti wafers |

| Expandable Functions | Rocking nkhaus tsom xam, 3D mapping, stacking ntaus ntawv, kho qhov muag tsis pom kev (scratches, GBs) |

Txoj Cai Ua Haujlwm

1. X-ray Diffraction Foundation

- X-rays cuam tshuam nrog atomic nuclei thiab electrons nyob rau hauv siv lead ua lattice, tsim cov qauv diffraction. Bragg Txoj Cai (nλ = 2d sinθ) tswj kev sib raug zoo ntawm lub kaum sab xis (θ) thiab lattice spacing (d).

Cov neeg ntes ntes cov qauv no, uas tau txheeb xyuas kom rov tsim kho cov qauv crystallographic.

2. Omega Scanning Technology

- Cov siv lead ua rotates tsis tu ncua nyob ib ncig ntawm lub axis ruaj thaum X-rays teeb nws.

- Cov neeg ntes tau sau cov cim diffraction hla ntau lub dav hlau crystallographic, ua rau kev txiav txim siab tag nrho cov lattice orientation hauv 5 vib nas this.

3. Rocking Curve Analysis

- Tsau lub kaum sab xis nrog qhov sib txawv ntawm X-ray qhov xwm txheej los ntsuas qhov dav dav (FWHM), ntsuas qhov tsis xws ntawm lattice thiab strain.

4. Automated tswj

- PLC thiab touchscreen interfaces pab kom preset txiav cov ces kaum, lub sij hawm tawm tswv yim, thiab kev koom ua ke nrog cov cav tov rau kaw-voj tswj.

Qhov zoo thiab nta

1. Precision thiab Efficiency

- Angular qhov tseeb ± 0.001 °, kev daws teeb meem tsis txaus ntseeg <30 arcseconds.

- Omega scan ceev yog 200 × sai dua li cov tshuaj Theta ib txwm muaj.

2. Modularity thiab Scalability

- Expandable rau cov ntawv tshwj xeeb (xws li, SiC wafers, turbine hniav).

- Kev koom ua ke nrog MES systems rau kev soj ntsuam kev tsim khoom hauv lub sijhawm.

3. Compatibility thiab Stability

- Ua raws li cov qauv zoo li qub (piv txwv li, tawg sapphire ingots).

- Cua txias tsim kom txo tau cov kev tu ncua.

4. Kev ua haujlwm ntse

- Ib-nias calibration thiab ua haujlwm ntau.

- Nws pib-calibration nrog siv lead ua kom txo qis tib neeg kev ua yuam kev.

Daim ntawv thov

1. Semiconductor Manufacturing

- Wafer dicing orientation: Txiav txim Si, SiC, GaN wafer orientations rau optimized txiav efficiency.

- Daim ntawv qhia qhov tsis xws luag: txheeb xyuas qhov chaw khawb los yog dislocations los txhim kho nti tawm.

2. Cov khoom siv kho qhov muag

- Nonlinear crystals (piv txwv li, LBO, BBO) rau cov khoom siv laser.

- Sapphire wafer siv nto cim rau LED substrates.

3. Ceramics thiab Composites

- Txheeb xyuas cov kab lis kev cai hauv Si3N4 thiab ZrO2 rau cov ntawv thov kub.

4. Kev Tshawb Fawb thiab Kev Tswj Xyuas Zoo

- Cov tsev kawm ntawv qib siab/labs rau kev txhim kho cov khoom tshiab (xws li, high-entropy alloys).

- Muaj QC los xyuas kom meej cov khoom sib xws.

XKH's Services

XKH muaj kev txhawb nqa thoob ntiaj teb kev txhawb nqa rau wafer orientation instruments, suav nrog kev teeb tsa, txheej txheem parameter optimization, rocking curve analysis, thiab 3D defect mapping. Cov kev daws teeb meem (piv txwv li, ingot stacking thev naus laus zis) yog muab los txhim kho cov khoom siv hluav taws xob thiab cov khoom siv kho qhov muag ntau dua 30%. Pab neeg mob siab rau ua qhov kev cob qhia ntawm qhov chaw, thaum 24/7 cov chaw taws teeb txhawb nqa thiab hloov cov khoom seem sai kom ntseeg tau cov khoom siv.