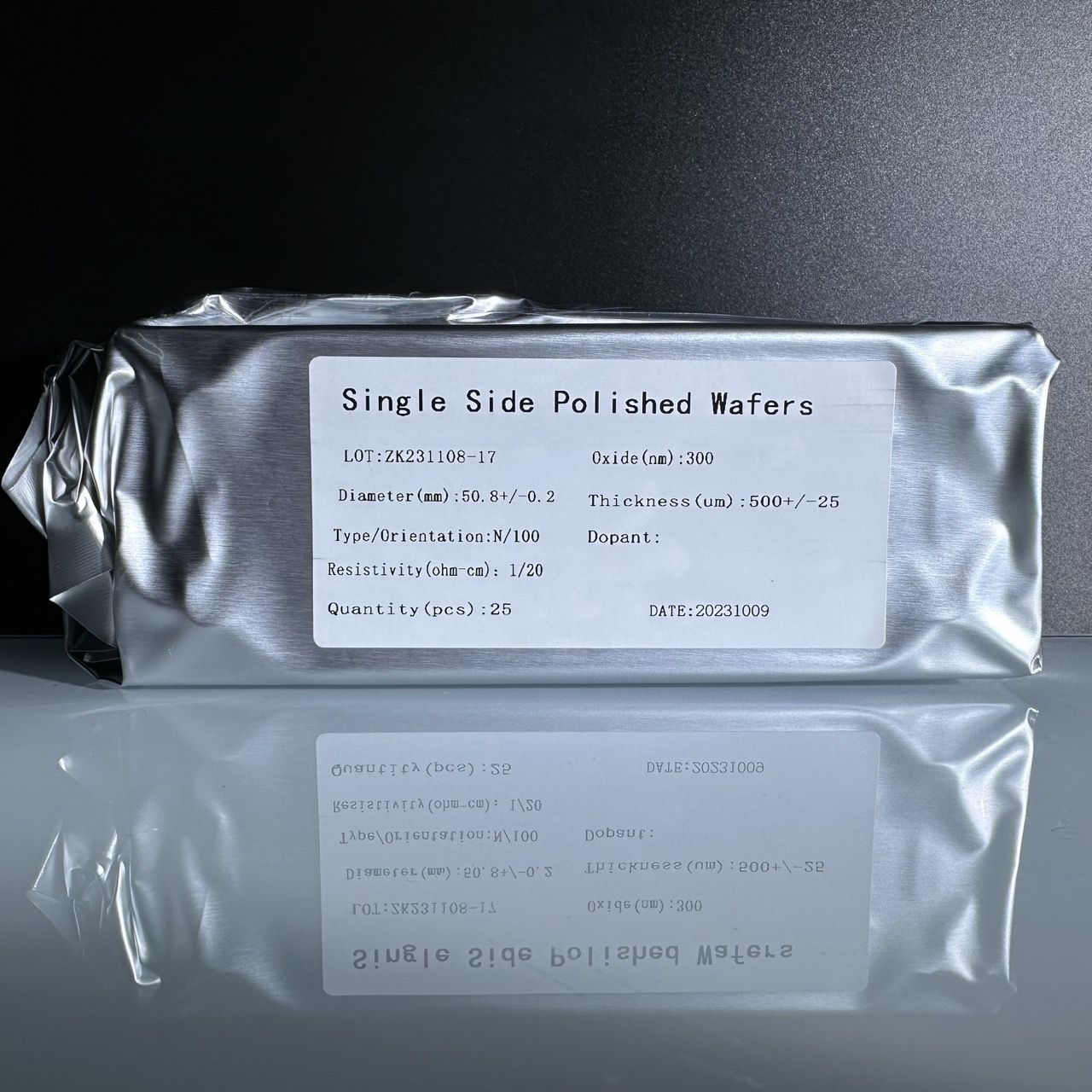

2 nti 50.8mm Silicon wafer FZ N-Hom SSP

Taw qhia ntawm wafer box

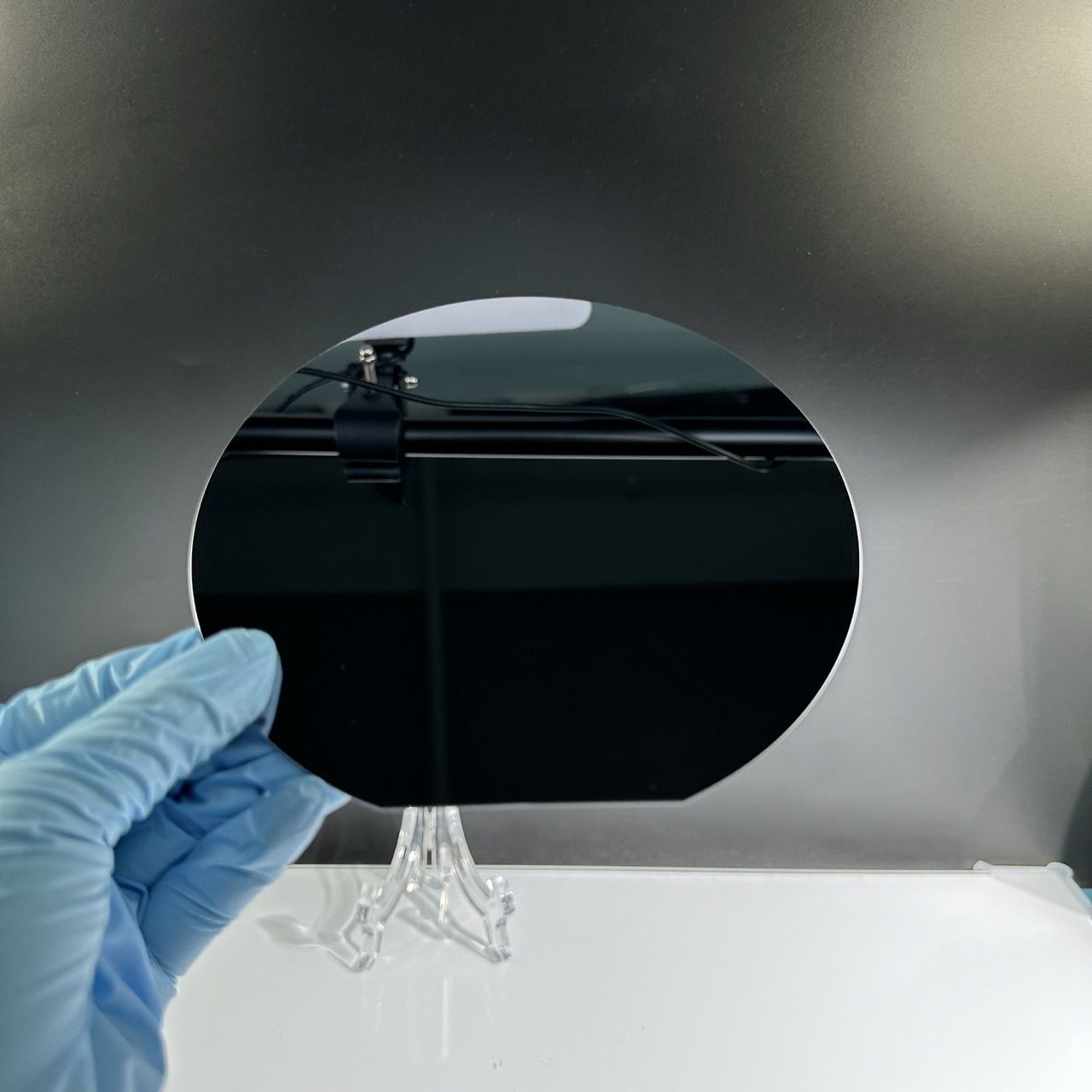

Lub 2-nti wafer yog ib qho me me silicon substrate uas feem ntau siv los ua cov khoom siv hluav taws xob xws li cov khoom siv hluav taws xob me me thiab cov khoom siv hluav taws xob. Nws siv suav nrog, tab sis tsis txwv rau, micro sensors, micro actuators, thiab micro mechanical devices. Vim nws qhov me me, kev lag luam pom zoo yuav yog nyob rau hauv kev lag luam microelectronics thiab hauv kev siv sensor. Tsis tas li ntawd, nrog kev txhim kho ntawm IoT, cov khoom siv hnav, thiab lwm yam kev lag luam, qhov kev thov rau cov khoom siv hluav taws xob me me thiab cov khoom siv hluav taws xob tsawg yuav nce ntxiv, uas tseem ua rau kev txhim kho kev lag luam rau 2-nti silicon wafers.

| Silicon Wafer Technology: Wafer Loj thiab Thickness | ||

| Thickness Ntau | Qhov zoo | Kev txiav txim siab |

| Me Thickness | Txhim kho thermal conductivity Txo warpage Compaction thiab miniaturization | Txo cov neeg kho tshuab lub zog Susceptibility rau breakage |

| Loj Thickness | Txhim kho mechanical kev ncaj ncees Tsawg qhov tsis zoo rau kev ntxhov siab vim muaj qhov tsis xws luag | Tsawg thermal conductivity Nce warpage muaj peev xwm |

| 300 mm diam | Kev lag luam-tus qauv Zoo tagnrho tsim khoom thiab nqi | Nruab nrab susceptibility rau defect |

| 450 mm diam | Ntau dua nti ntom nti rau wafer Ua kom cov khoom tsim tau thiab cov nqi ua tau zoo | Nce susceptibility rau defect Kev nqis peev tseem ceeb yog xav tau rau cov cuab yeej siv thiab kev tsim kho vaj tse kom tau txais txiaj ntsig ntau dua |

Txawm hais tias muaj ntau ntau cov ntaub ntawv siv los tsim cov khoom siv hluav taws xob, silicon yog nyob deb tshaj plaws. Silicon tsis yog tsuas yog yooj yim rau kev ua haujlwm nrog, tab sis nws kuj tseem muaj ntau heev uas nws nthuav tawm qhov kev xaiv zoo tshaj plaws.

Txij li thaum silicon wafers muaj ntau yam kev siv tseem ceeb thiab kev siv hauv lub neej txhua hnub, categorizing qhov tseem ceeb tshaj plaws tuaj yeem ua haujlwm txaus ntshai. Txij li thaum silicon wafers tau siv dav thiab muaj ntau daim ntawv thov, nws yuav tsis ncaj ncees rau kev tsom mus rau tsuas yog ib qho ntawm nws daim ntawv thov. Ntawm no, peb yuav tsom mus rau cov ntawv thov thiab kev siv cov silicon wafers hauv kev siv cov khoom siv hluav taws xob. Yog tias koj xav kawm ntxiv txog qhov tseem ceeb ntawm silicon wafers hauv lub neej txhua hnub, nyeem rau.

Cov semiconductor nrov tshaj plaws yog silicon vim nws qhov kub thiab txias thiab kev txav mus los ntawm chav tsev kub, txawm hais tias lwm cov neeg siv khoom sib txawv siv hauv cov ntawv thov tshwj xeeb. Hauv cov khoom siv hluav taws xob, nws yog qhov kev xaiv zoo tshaj plaws vim tias tam sim no dhau los ntawm silicon semiconductors sai dua li cov neeg siv feem ntau.

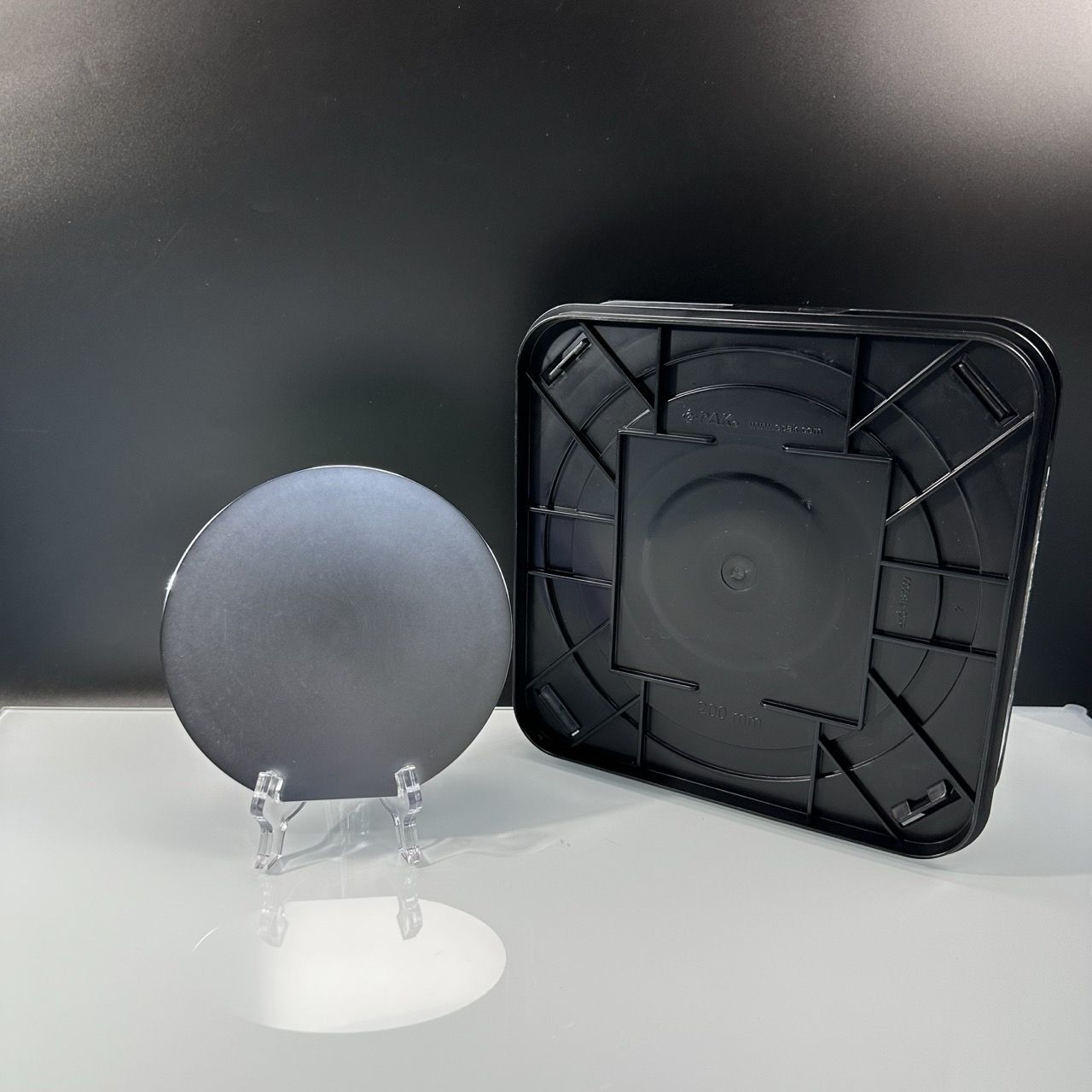

Daim duab qhia ntxaws