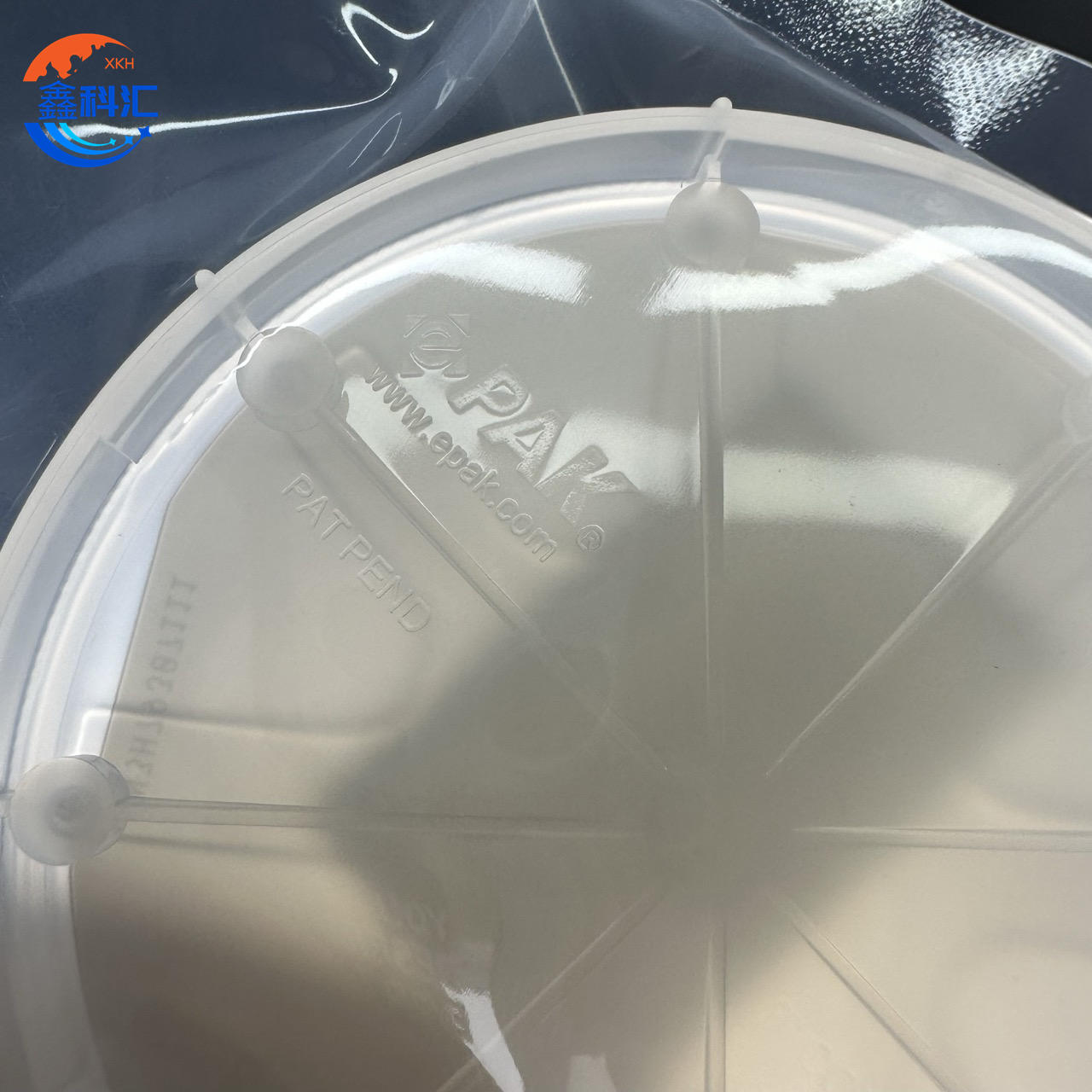

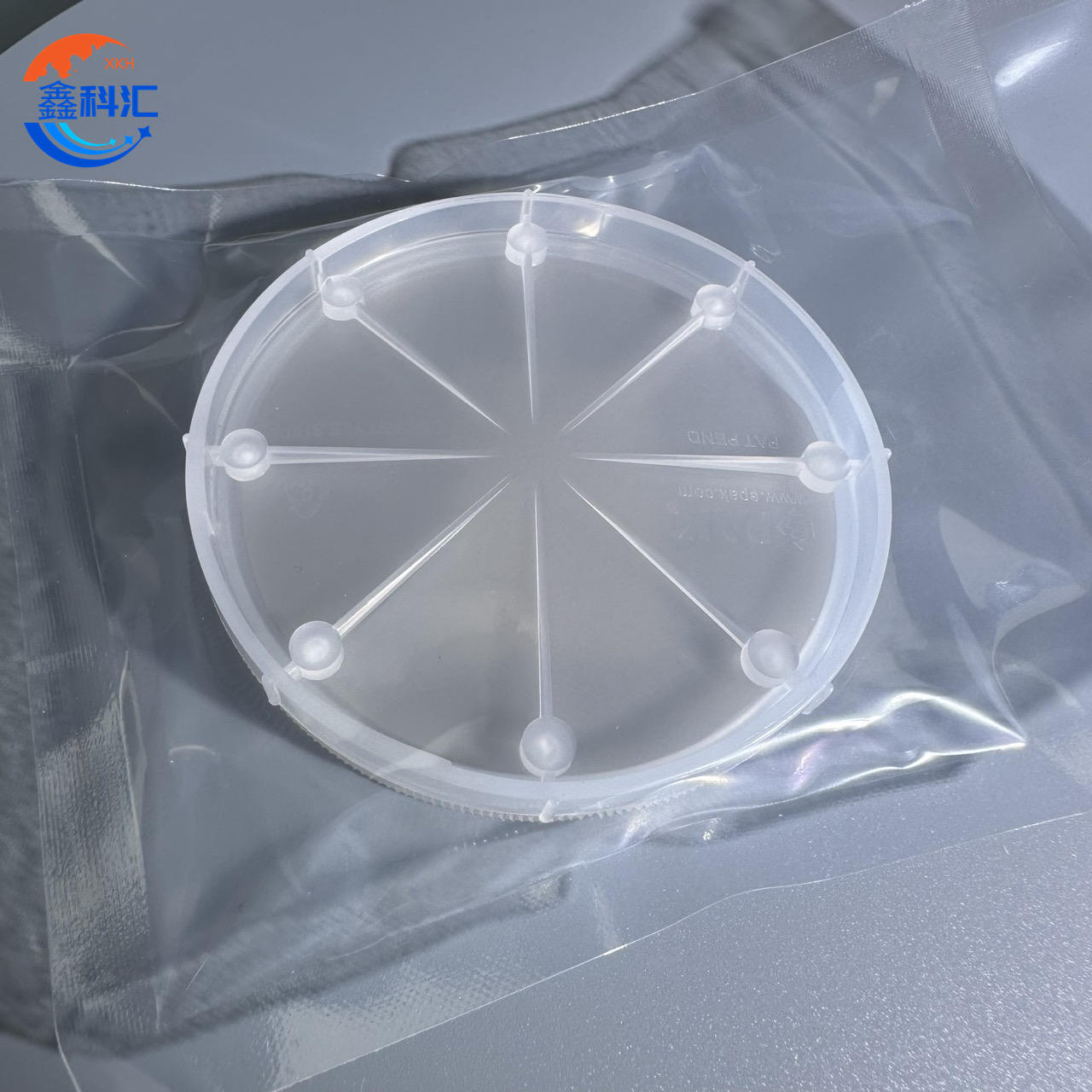

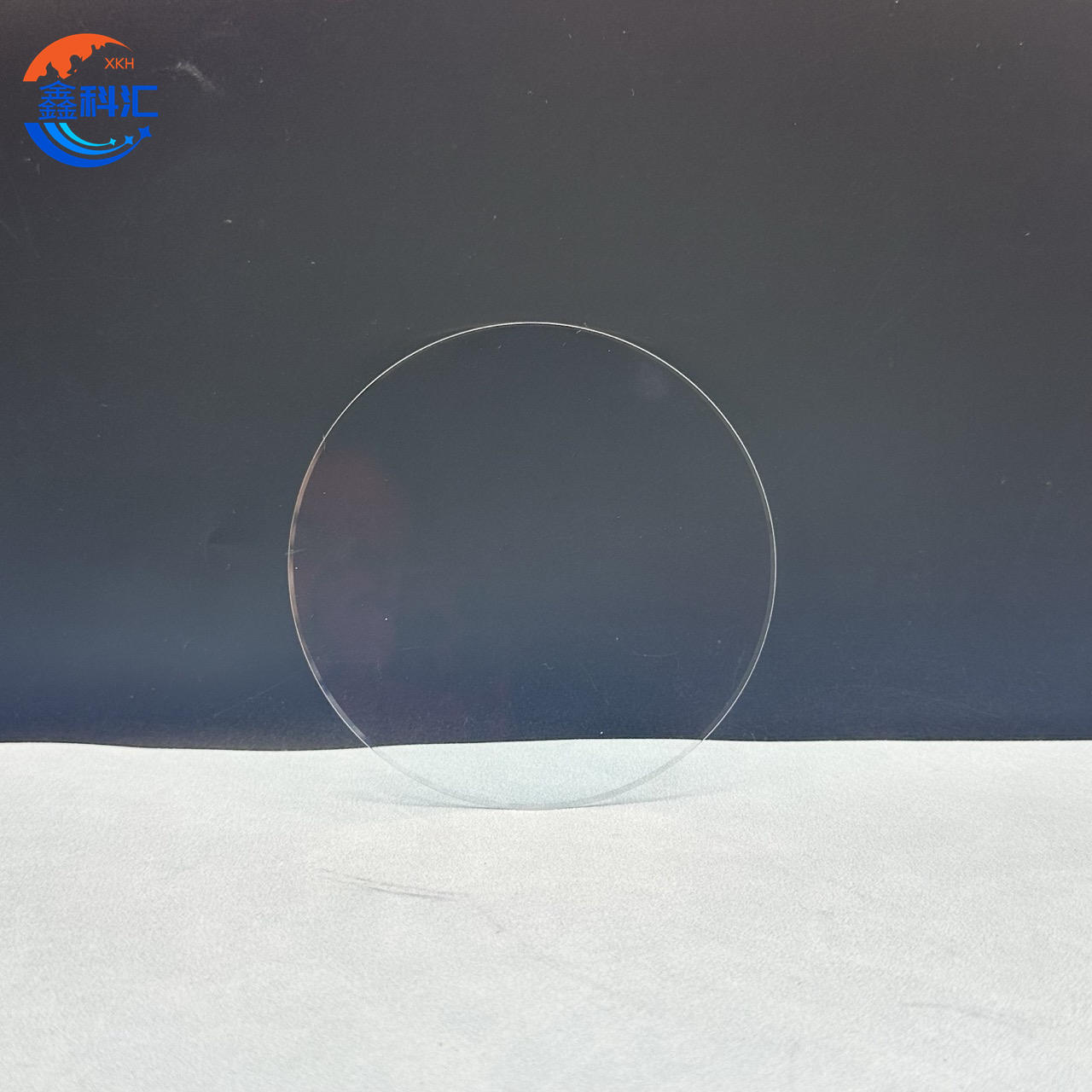

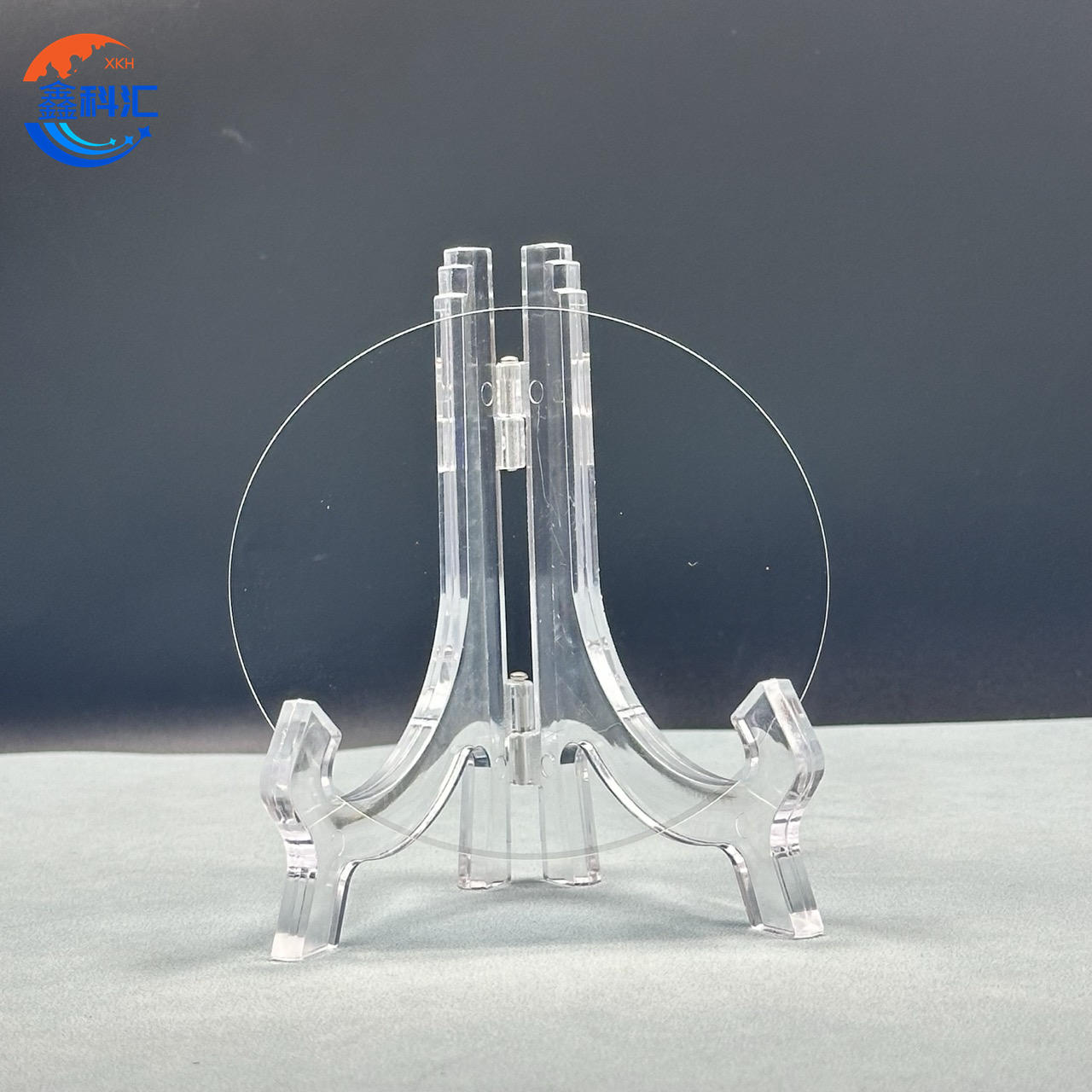

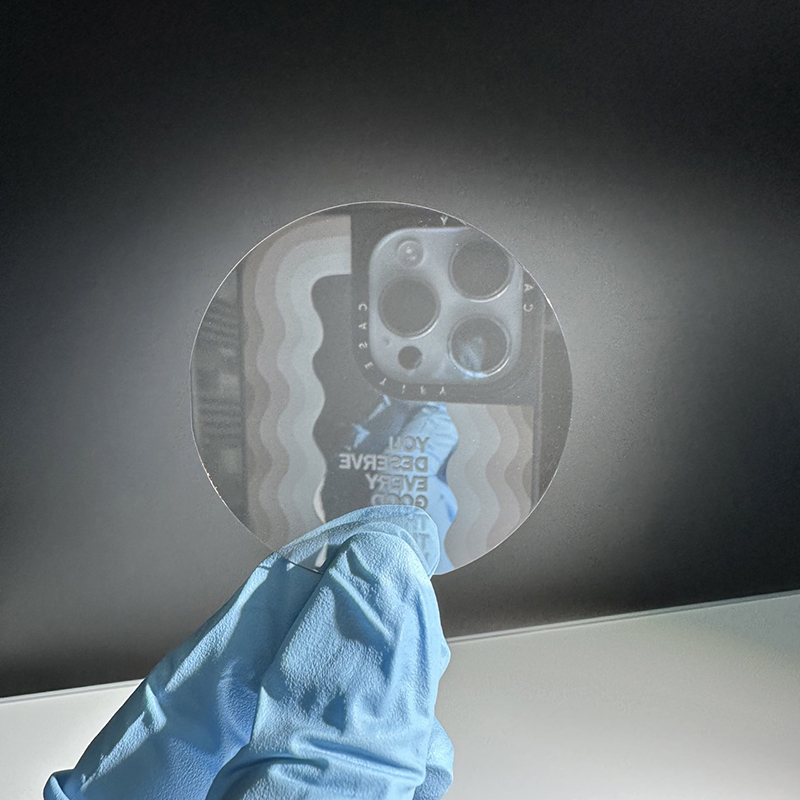

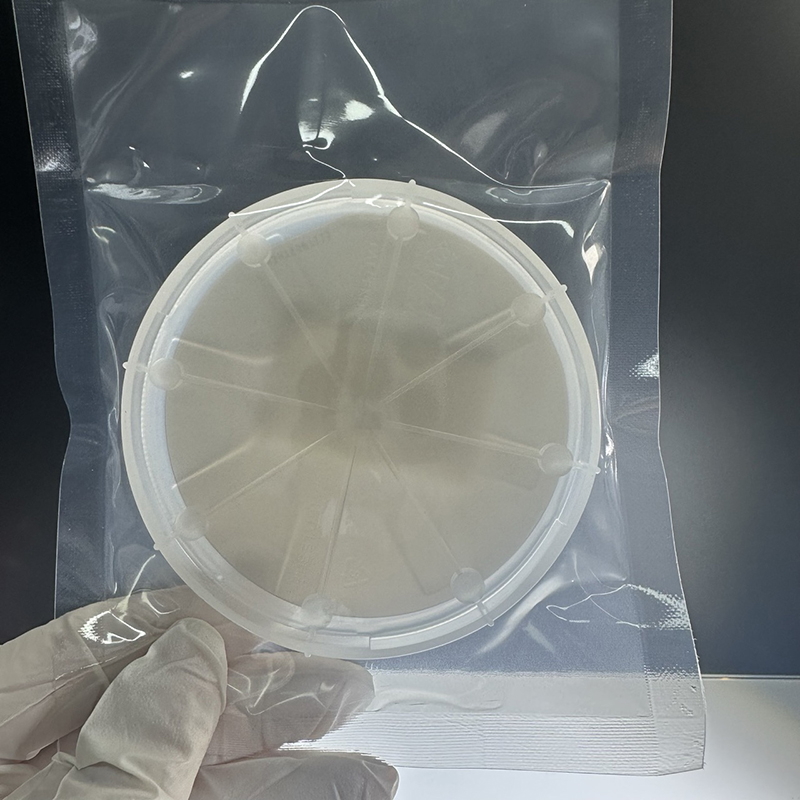

3 nti High Purity (Undoped) Silicon Carbide Wafers semi-Insulating Sic Substrates (HPSl)

Cov khoom

1. Lub cev thiab lub cev muaj zog

● Khoom siv: High Purity (Undoped) Silicon Carbide (SiC)

● Dia: 3 nti (76.2 mm)

●Thickness: 0.33-0.5 hli, customizable raws li daim ntawv thov.

●Crystal Structure: 4H-SiC polytype nrog hexagonal lattice, paub txog kev ua haujlwm siab electron thiab thermal stability.

● Kev taw qhia:

oStandard: [0001] (C-plane), haum rau ntau yam kev siv.

oOptional: Off-axis (4 ° lossis 8 ° qaij) rau kev txhim kho epitaxial kev loj hlob ntawm cov txheej txheem.

● Flatness: Tag nrho cov thickness variation (TTV) ●Surface Quality:

oPolished rau oLow-defect ntom (<10/cm² micropipe ntom). 2. Cov Khoom Siv Hluav Taws Xob ●Resistivity:> 109^99 Ω·cm, tswj los ntawm kev tshem tawm ntawm txhob txwm dopants.

● Dielectric Strength: High voltage endurance nrog tsawg dielectric poob, zoo tagnrho rau high-power daim ntaub ntawv.

●Thermal Conductivity: 3.5-4.9 W / cm·K, ua kom muaj cua sov zoo hauv cov khoom siv ua haujlwm siab.

3. Thermal thiab Mechanical Properties

●Wide Bandgap: 3.26 eV, txhawb kev lag luam nyob rau hauv high voltage, high kub, thiab high radiation tej yam kev mob.

● Hardness: Mohs nplai 9, kom ntseeg tau tias muaj zog tiv thaiv kev siv tshuab thaum ua haujlwm.

●Thermal Expansion Coefficient: 4.2 × 10−6 / K4.2 \times 10^{-6}/\text{K}4.2 × 10−6/K, kom ntseeg tau qhov seem stability nyob rau hauv kub variations.

| Parameter | Qib ntau lawm | Qib tshawb fawb | Dummy Qib | Chav tsev |

| Qib | Qib ntau lawm | Qib tshawb fawb | Dummy Qib | |

| Txoj kab uas hla | 76.2 ± 0.5 | 76.2 ± 0.5 | 76.2 ± 0.5 | mm |

| Thickness | 500 ± 25 | 500 ± 25 | 500 ± 25 | µm |

| Wafer Orientation | On-axis: <0001> ± 0.5° | On-axis: <0001> ± 2.0° | On-axis: <0001> ± 2.0° | degree |

| Micropipe Density (MPD) | ≤ 1 | ≤ 5 | ≤ 10 | cm-2^-2-2 |

| Hluav taws xob Resistivity | ≥1E10 | ≥1E5 | ≥1E5 | Ω·cm |

| Dopant | Undoped | Undoped | Undoped | |

| Thawj Txoj Kev Ncaj Ncees | {1-100} ± 5.0° | {1-100} ± 5.0° | {1-100} ± 5.0° | degree |

| Qhov Loj Loj Loj | 32.5 ± 3.0 | 32.5 ± 3.0 | 32.5 ± 3.0 | mm |

| Secondary Flat Length | 18.0 ± 2.0 | 18.0 ± 2.0 | 18.0 ± 2.0 | mm |

| Secondary Flat Orientation | 90 ° CW los ntawm thawj lub tiaj tus ± 5.0 ° | 90 ° CW los ntawm thawj lub tiaj tus ± 5.0 ° | 90 ° CW los ntawm thawj lub tiaj tus ± 5.0 ° | degree |

| Ntug Exclusion | 3 | 3 | 3 | mm |

| LTV/TTV/Bow/Warp | 3 / 10 / ± 30 / 40 | 3 / 10 / ± 30 / 40 | 5 / 15 / ± 40 / 45 | µm |

| Nto Roughness | Lub ntsej muag: CMP, C-lub ntsej muag: Polished | Lub ntsej muag: CMP, C-lub ntsej muag: Polished | Lub ntsej muag: CMP, C-lub ntsej muag: Polished | |

| Cracks (High-Intensity Light) | Tsis muaj | Tsis muaj | Tsis muaj | |

| Hex Phaj (High-Intensity Light) | Tsis muaj | Tsis muaj | Thaj tsam 10% | % |

| Polytype Areas (High-Intensity Light) | Thaj tsam 5% | Cov cheeb tsam 20% | Thaj tsam 30% | % |

| Scratches (High-Intensity Light) | ≤ 5 khawb, cumulative ntev ≤ 150 | ≤ 10 khawb, cumulative ntev ≤ 200 | ≤ 10 khawb, cumulative ntev ≤ 200 | mm |

| Ntug Chiping | Tsis muaj ≥ 0.5 mm dav / qhov tob | 2 tso cai ≤ 1 hli dav / qhov tob | 5 pub ≤ 5 mm dav / qhov tob | mm |

| Nto Cov Kab Mob | Tsis muaj | Tsis muaj | Tsis muaj |

Daim ntawv thov

1. Fais fab Electronics

Qhov dav bandgap thiab siab thermal conductivity ntawm HPSI SiC substrates ua rau lawv zoo tagnrho rau cov khoom siv hluav taws xob ua haujlwm hauv huab cua, xws li:

●High-Voltage Devices: suav nrog MOSFETs, IGBTs, thiab Schottky Barrier Diodes (SBDs) rau kev hloov hluav taws xob zoo.

●Renewable Energy Systems: Xws li hnub ci inverters thiab cua turbine controllers.

●Electric Tsheb (EVs): Siv nyob rau hauv inverters, chargers, thiab powertrain systems los txhim kho efficiency thiab txo qhov luaj li cas.

2. Kev siv RF thiab Microwave

Lub siab resistivity thiab tsis tshua muaj dielectric poob ntawm HPSI wafers yog qhov tseem ceeb rau xov tooj cua zaus (RF) thiab microwave systems, suav nrog:

●Telecommunication Infrastructure: Base chaw nres tsheb rau 5G tes hauj lwm thiab satellite kev sib txuas lus.

●Aerospace thiab Defense: Radar systems, phased-array antennas, thiab avionics Cheebtsam.

3. Optoelectronics

Lub pob tshab thiab dav bandgap ntawm 4H-SiC pab kom nws siv hauv optoelectronic li, xws li:

●UV Photodetectors: Rau ib puag ncig saib xyuas thiab kuaj mob.

●High-Power LEDs: Txhawb cov teeb pom kev zoo hauv lub xeev.

● Laser Diodes: Rau kev lag luam thiab kev siv kho mob.

4. Kev Tshawb Fawb thiab Kev Txhim Kho

HPSI SiC substrates tau dav siv hauv kev kawm thiab kev lag luam R & D labs rau kev tshawb nrhiav cov khoom siv qib siab thiab kev tsim khoom, suav nrog:

●Epitaxial Layer Loj hlob: Kev tshawb fawb txog kev txo qis thiab kev ua kom zoo dua txheej txheej.

●Carrier Mobility Studies: Kev tshawb xyuas ntawm cov khoom siv hluav taws xob thiab qhov chaw thauj khoom hauv cov khoom siv purity siab.

●Prototyping: Kev tsim kho thawj zaug ntawm cov khoom siv tshiab thiab cov khoom siv hluav taws xob.

Qhov zoo

Superior Quality:

High purity thiab tsawg defect ntom muab ib tug txhim khu kev qha platform rau advanced daim ntawv thov.

Thermal stability:

Cov khoom siv hluav taws xob zoo heev tso cai rau cov cuab yeej ua haujlwm tau zoo nyob rau hauv lub zog siab thiab kub.

Broad Compatibility:

Muaj kev taw qhia thiab kev cai thickness xaiv kom haum rau ntau yam khoom yuav tsum tau ua.

Durability:

Exceptional hardness thiab structural stability txo qhov hnav thiab deformation thaum ua thiab ua haujlwm.

Versatility:

Haum rau ntau yam kev lag luam, los ntawm lub zog tauj dua tshiab mus rau aerospace thiab kev sib txuas lus.

Xaus

Lub 3-nti High Purity Semi-Insulating Silicon Carbide wafer sawv cev rau lub pinnacle ntawm substrate technology rau high-power, high-frequency, thiab optoelectronic li. Nws ua ke ntawm cov thermal zoo, hluav taws xob, thiab cov khoom siv kho tshuab ua kom ntseeg tau tias kev ua tau zoo hauv qhov chaw nyuaj. Los ntawm lub zog hluav taws xob hluav taws xob thiab RF tshuab rau optoelectronics thiab R&D siab heev, cov HPSI substrates muab lub hauv paus rau tag kis kev tsim kho tshiab.

Yog xav paub ntxiv los yog muab qhov kev txiav txim, thov hu rau peb. Peb pab neeg ua haujlwm muaj peev xwm muab kev taw qhia thiab kev xaiv kho kom haum raws li koj xav tau.

Daim duab qhia ntxaws