Microjet Dej-Kev Taw Qhia Laser Txiav System rau Cov Khoom Siv Zoo

Qhov zoo tshaj plaws

1. Tsis muaj zog ua kom pom tseeb los ntawm kev taw qhia dej

Los ntawm kev siv lub dav hlau dej siab zoo ua lub laser waveguide, lub kaw lus tshem tawm huab cua cuam tshuam thiab ua kom pom tseeb tag nrho. Qhov tshwm sim yog ultra-nqaim txiav dav - me me li 20μm - nrog cov ntse ntse, huv si.

2. Tsawg kawg Thermal Footprint

Lub tshuab hluav taws xob hluav taws xob hauv lub sijhawm tiag tiag ua kom thaj chaw muaj kev kub ntxhov tsis dhau 5μm, tseem ceeb heev rau kev khaws cia cov khoom ua tau zoo thiab tsis txhob microcracks.

3. Wide Material Compatibility

Dual-wavelength tso zis (532nm / 1064nm) muab kev txhawb nqa kom zoo dua qub, ua rau lub tshuab hloov tau mus rau ntau yam substrates, los ntawm cov pob tshab pob tshab rau opaque ceramics.

4. High-Speed, High-Precision Motion Control

Nrog rau cov kev xaiv rau linear thiab ncaj-tsav motors, lub kaw lus txhawb siab-throughput xav tau yam tsis muaj kev cuam tshuam qhov tseeb. Tsib-axis tsab ntawv tsa suab ntxiv ua rau cov qauv tsim thiab ntau txoj kev txiav.

5. Modular thiab Scalable Design

Cov neeg siv tuaj yeem tsim kho cov txheej txheem kev teeb tsa raws li daim ntawv thov kev thov - los ntawm kev sim ua qauv rau kev tsim khoom siv-ua kom haum thoob plaws R&D thiab cov chaw lag luam.

Cov cheeb tsam thov

Third-Generation Semiconductors:

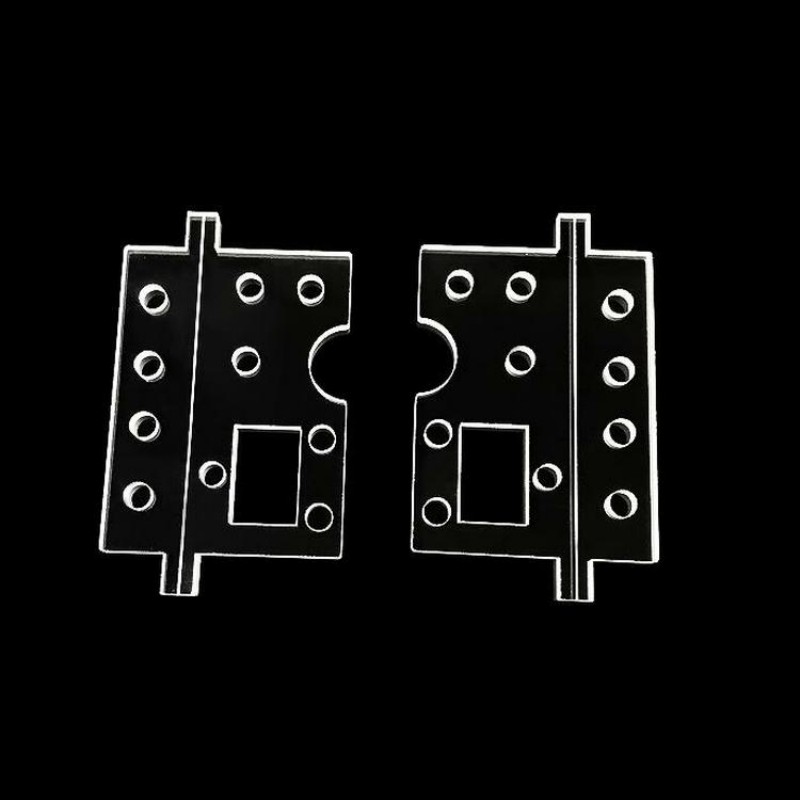

Zoo meej rau SiC thiab GaN wafers, lub kaw lus ua dicing, trenching, thiab slicing nrog tshwj xeeb ntug kev ncaj ncees.

Pob zeb diamond thiab Oxide Semiconductor Machining:

Siv rau kev txiav thiab drilling cov ntaub ntawv hardness zoo li ib lub pob zeb diamond thiab Ga₂O₃, tsis muaj carbonization lossis thermal deformation.

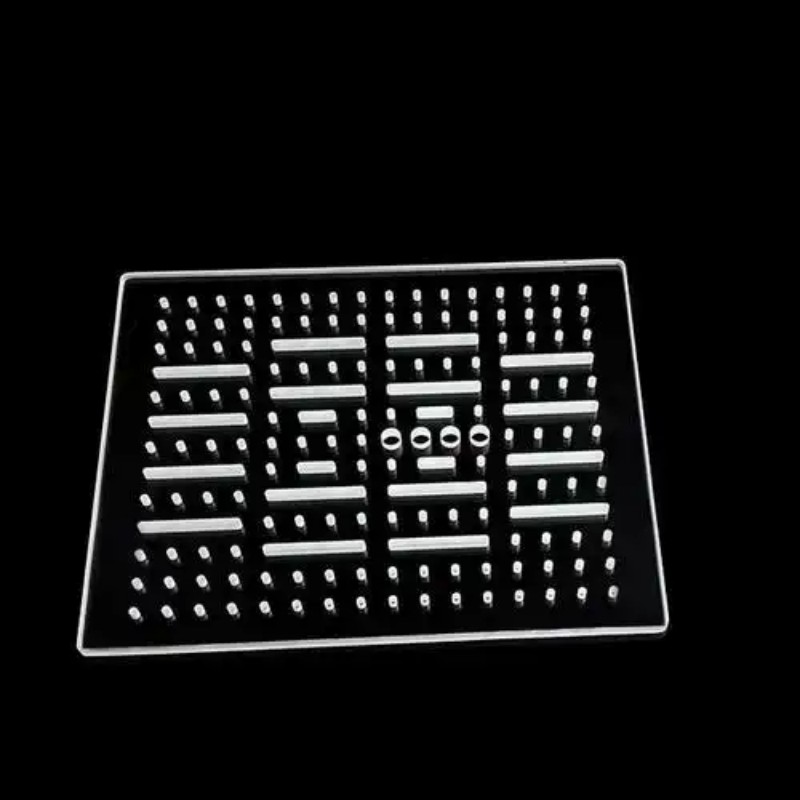

Advanced Aerospace Cheebtsam:

Txhawb cov qauv tsim ntawm high-tensile ceramic composites thiab superalloys rau dav hlau cav thiab satellite Cheebtsam.

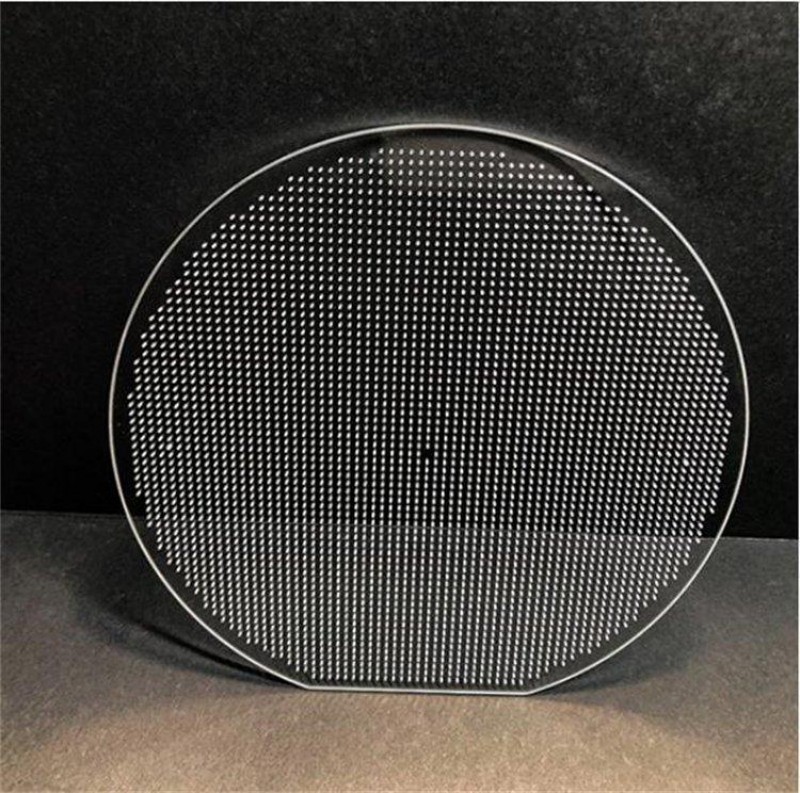

Photovoltaic thiab ceramic substrates:

Pab kom tsis pub muaj burr-free txiav ntawm nyias wafers thiab LTCC substrates, nrog rau los ntawm-qhov thiab qhov milling rau interconnects.

Sintillators thiab Optical Cheebtsam:

Ua kom lub ntsej muag du thiab sib kis hauv cov khoom siv kho qhov muag tsis zoo xws li Ce: YAG, LSO, thiab lwm yam.

Specification

| Feature | Specification |

| Laser Source | DPSS Nd:YAG |

| Kev xaiv Wavelength | 532nm / 1064nm |

| Hwj chim theem | 50/100/200 W |

| Precision | ± 5 hli |

| Txiav dav | Raws li nqaim li 20μm |

| Thaum tshav kub kub cuam tshuam | ≤ 5μm |

| Motion Type | Linear / Direct Drive |

| Cov ntaub ntawv txhawb nqa | SiC, GaN, Pob zeb diamond, Ga₂O₃, thiab lwm yam. |

Vim li cas thiaj xaiv Qhov System?

● Tshem tawm cov teeb meem laser machining xws li thermal cracking thiab ntug chipping

● Txhim kho cov txiaj ntsig thiab kev sib xws rau cov khoom siv uas raug nqi siab

● Adaptable rau ob qho tib si pilot-scale thiab industrial siv

● Yav tom ntej-pov thawj platform rau evolving ntaub ntawv science

Q&A

Q1: Cov ntaub ntawv dab tsi tuaj yeem ua qhov txheej txheem no?

A: Lub kaw lus tshwj xeeb yog tsim los rau cov khoom siv tawv thiab nkig siab. Nws tuaj yeem ua haujlwm zoo silicon carbide (SiC), gallium nitride (GaN), pob zeb diamond, gallium oxide (Ga₂O₃), LTCC substrates, aerospace composites, photovoltaic wafers, thiab scintillator crystals xws li Ce:YAG lossis LSO.

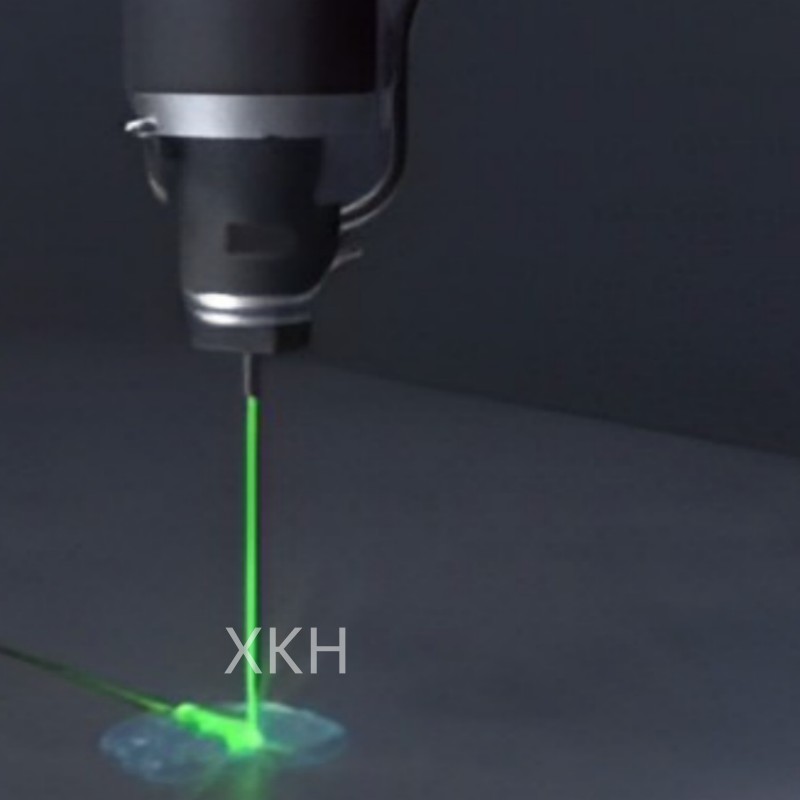

Q2: Ua li cas dej-coj laser tshuab ua haujlwm?

A: Nws siv lub tshuab hluav taws xob siab microjet dej los coj lub teeb ci laser ntawm tag nrho cov kev xav sab hauv, ua haujlwm zoo ntawm lub zog laser nrog cov tawg me me. Qhov no ua kom pom tseeb ultra-nplua, tsis tshua muaj thermal load, thiab precision txiav nrog kab dav mus txog 20μm.

Q3: Dab tsi yog qhov muaj zog laser teeb tsa?

A: Cov neeg siv khoom tuaj yeem xaiv los ntawm 50W, 100W, thiab 200W laser fais fab kev xaiv nyob ntawm lawv cov kev ua haujlwm ceev thiab kev daws teeb meem xav tau. Tag nrho cov kev xaiv ua kom muaj siab beam stability thiab repeatability.

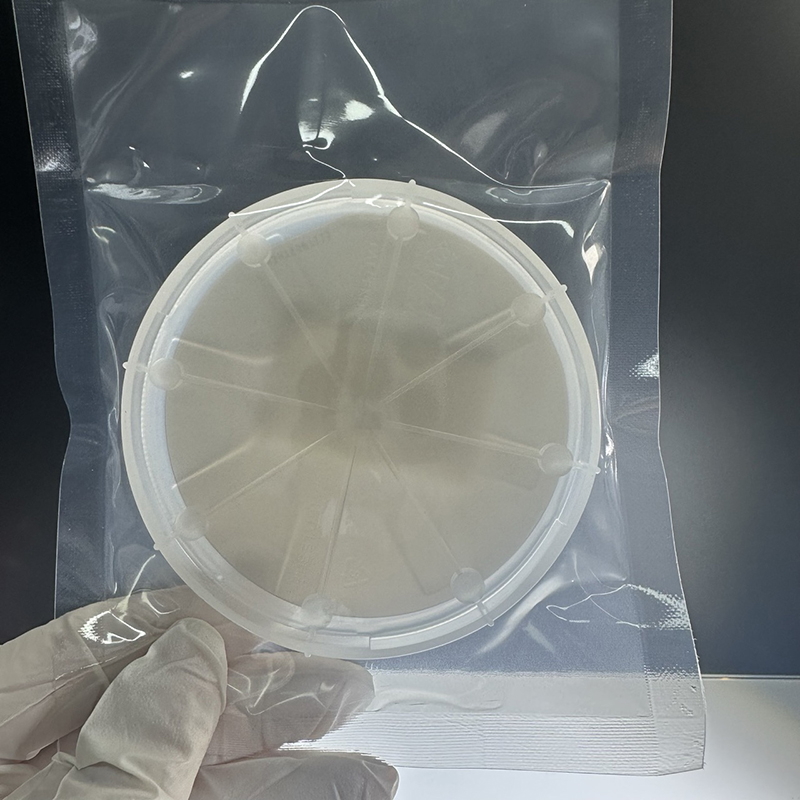

Daim duab qhia ntxaws