Taw qhia rau silicon carbide

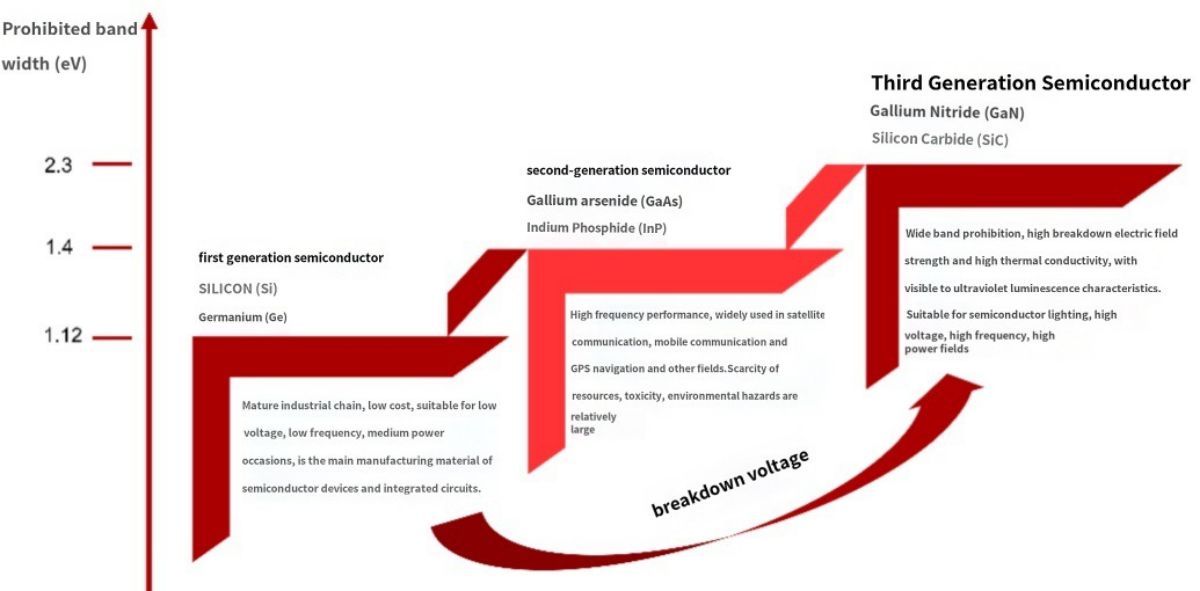

Silicon carbide (SiC) yog cov khoom siv semiconductor uas muaj cov pa roj carbon thiab silicon, uas yog ib qho ntawm cov khoom siv zoo tshaj plaws rau kev ua kom kub, siab zaus, siab zog thiab siab voltage.Piv nrog rau cov khoom siv silicon tsoos (Si), qhov sib txawv ntawm silicon carbide yog 3 npaug ntawm silicon.Lub thermal conductivity yog 4-5 npaug ntawm silicon;Lub zog tawg yog 8-10 npaug ntawm silicon;Cov hluav taws xob saturation drift tus nqi yog 2-3 npaug ntawm silicon, uas ua tau raws li cov kev xav tau ntawm kev lag luam niaj hnub rau lub zog siab, siab voltage thiab siab zaus.Nws yog tsuas yog siv rau kev tsim cov high-speed, high-frequency, high-power thiab lub teeb-emitting hluav taws xob Cheebtsam.Daim ntawv thov nram qab no suav nrog daim phiaj ntse, lub zog tshiab tsheb, photovoltaic cua zog, 5G kev sib txuas lus, thiab lwm yam. Silicon carbide diodes thiab MOSFETs tau ua lag luam.

Kub kub kuj.Qhov sib txawv band dav ntawm silicon carbide yog 2-3 npaug ntawm silicon, cov electrons tsis yooj yim rau kev hloov pauv ntawm qhov kub thiab txias, thiab tuaj yeem tiv taus qhov kub thiab txias, thiab thermal conductivity ntawm silicon carbide yog 4-5 npaug ntawm silicon, ua rau cov cuab yeej cua sov dissipation yooj yim dua thiab qhov txwv kev ua haujlwm kub siab dua.Kev kub siab ua haujlwm tuaj yeem ua kom muaj zog ceev ceev thaum txo cov kev xav tau ntawm cov cua txias, ua rau lub davhlau ya nyob twg sib dua thiab me dua.

Nrog kev kub siab.Lub zog hluav taws xob tawg ntawm silicon carbide yog 10 npaug ntawm silicon, uas tuaj yeem tiv taus qhov hluav taws xob ntau dua thiab tsim nyog rau cov khoom siv hluav taws xob ntau.

High zaus kuj.Silicon carbide muaj ib tug saturated electron drift tus nqi ob zaug ntawm silicon, uas ua rau tsis muaj tam sim no tailing thaum lub sij hawm kaw, uas yuav ua tau zoo txhim kho lub zaus hloov ntawm lub ntaus ntawv thiab paub lub miniaturization ntawm lub ntaus ntawv.

Tsawg zog poob.Piv nrog rau cov khoom siv silicon, silicon carbide muaj qhov ua haujlwm tsis zoo thiab tsis tshua muaj kev poob.Nyob rau tib lub sij hawm, qhov siab band-nruab dav ntawm silicon carbide zoo heev txo cov xau tam sim no thiab lub zog poob.Tsis tas li ntawd, cov khoom siv silicon carbide tsis muaj qhov tshwm sim tam sim no thaum lub sijhawm kaw, thiab kev hloov pauv tsis tshua muaj.

Silicon carbide kev lag luam saw

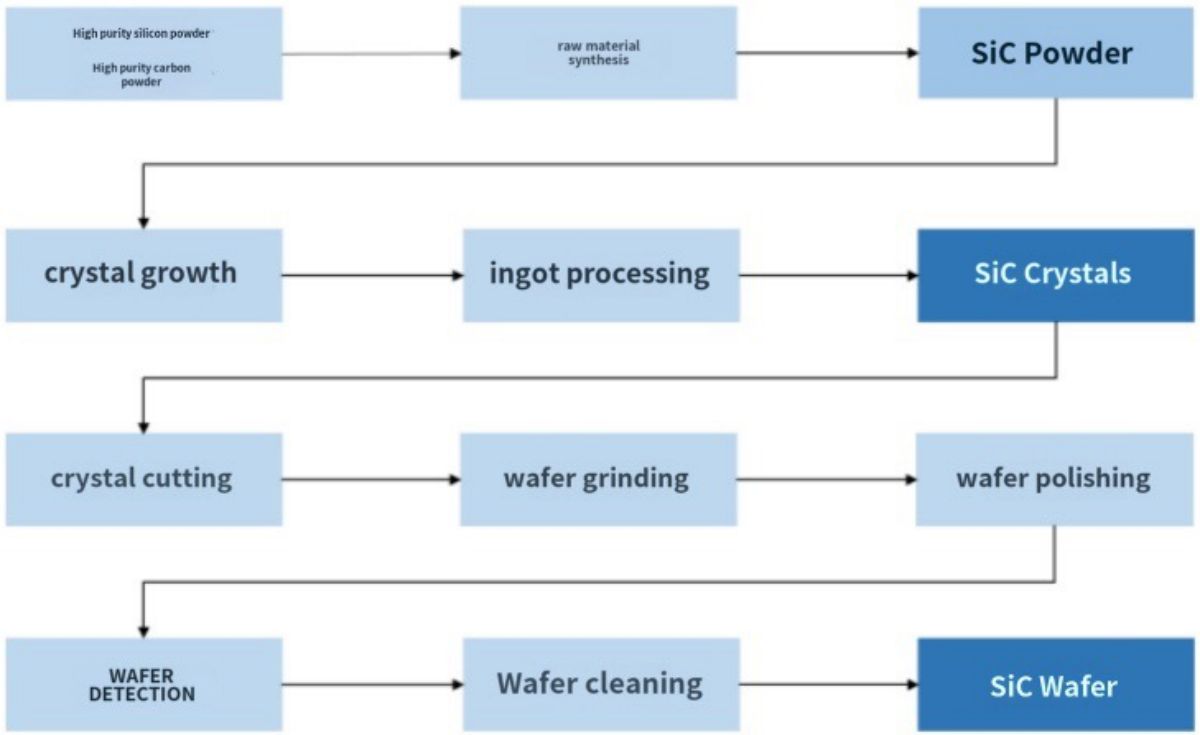

Nws feem ntau suav nrog substrate, epitaxy, ntaus ntawv tsim, tsim, sealing thiab lwm yam.Silicon carbide los ntawm cov khoom siv rau cov khoom siv hluav taws xob semiconductor yuav muaj kev loj hlob ib leeg siv lead ua, ingot slicing, epitaxial kev loj hlob, wafer tsim, tsim, ntim thiab lwm yam txheej txheem.Tom qab lub synthesis ntawm silicon carbide hmoov, silicon carbide ingot yog ua ntej, thiab ces cov silicon carbide substrate yog tau los ntawm slicing, sib tsoo thiab polishing, thiab daim ntawv epitaxial yog tau los ntawm epitaxial loj hlob.Lub epitaxial wafer yog ua los ntawm silicon carbide los ntawm lithography, etching, ion implantation, hlau passivation thiab lwm yam txheej txheem, lub wafer yog txiav mus rau hauv tuag, lub ntaus ntawv yog ntim, thiab cov cuab yeej muab tso rau hauv ib lub plhaub tshwj xeeb thiab sib sau ua ke rau hauv ib lub module.

Upstream ntawm kev lag luam saw 1: substrate - siv lead ua kev loj hlob yog cov txheej txheem tseem ceeb txuas

Silicon carbide substrate suav txog li 47% ntawm tus nqi ntawm cov khoom siv silicon carbide, kev tsim kev lag luam siab tshaj plaws, tus nqi loj tshaj plaws, yog lub hauv paus ntawm lub neej yav tom ntej loj-scale industrialization ntawm SiC.

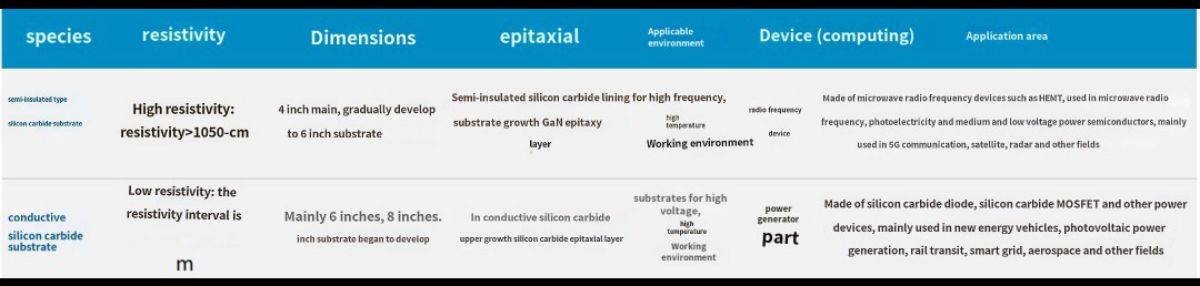

Los ntawm qhov kev xav ntawm cov khoom siv hluav taws xob sib txawv, cov khoom siv silicon carbide substrate tuaj yeem muab faib ua cov khoom siv hluav taws xob (resistivity cheeb tsam 15 ~ 30mΩ·cm) thiab semi-insulated substrates (resistivity siab dua 105Ω·cm).Ob hom substrates no yog siv los tsim cov khoom siv sib cais xws li cov khoom siv hluav taws xob thiab cov xov tooj cua zaus raws li kev loj hlob ntawm epitaxial.Ntawm lawv, semi-insulated silicon carbide substrate yog tsuas yog siv nyob rau hauv kev tsim cov gallium nitride RF li, photoelectric li thiab hais txog.Los ntawm kev loj hlob gan epitaxial txheej ntawm semi-insulated SIC substrate, sic epitaxial phaj yog npaj, uas tuaj yeem npaj ntxiv rau hauv HEMT gan iso-nitride RF li.Conductive silicon carbide substrate feem ntau yog siv los tsim cov khoom siv hluav taws xob.Sib txawv ntawm cov khoom siv hluav taws xob silicon cov txheej txheem tsim khoom, cov khoom siv hluav taws xob silicon carbide tsis tuaj yeem ua ncaj qha rau ntawm silicon carbide substrate, silicon carbide epitaxial txheej yuav tsum tau cog rau ntawm cov khoom siv hluav taws xob kom tau txais cov ntawv silicon carbide epitaxial, thiab cov epitaxial. txheej yog tsim los ntawm Schottky diode, MOSFET, IGBT thiab lwm yam khoom siv fais fab.

Silicon carbide hmoov tau tsim los ntawm siab purity carbon hmoov thiab siab purity silicon hmoov, thiab ntau qhov sib txawv ntawm silicon carbide ingot tau loj hlob nyob rau hauv tshwj xeeb kub teb, thiab ces silicon carbide substrate yog tsim los ntawm ntau yam txheej txheem.Cov txheej txheem tseem ceeb suav nrog:

Raw khoom synthesis: Lub siab-purity silicon hmoov + toner yog tov raws li tus qauv, thiab cov tshuaj tiv thaiv yog nqa tawm nyob rau hauv cov tshuaj tiv thaiv chamber nyob rau hauv lub kub kub saum toj no 2000 ° C los ua ke cov silicon carbide hais nrog tej yam siv lead ua thiab particle. qhov loj.Tom qab ntawd los ntawm crushing, tshuaj ntsuam, tu thiab lwm yam txheej txheem, kom tau raws li qhov yuav tsum tau ntawm siab purity silicon carbide hmoov raw cov ntaub ntawv.

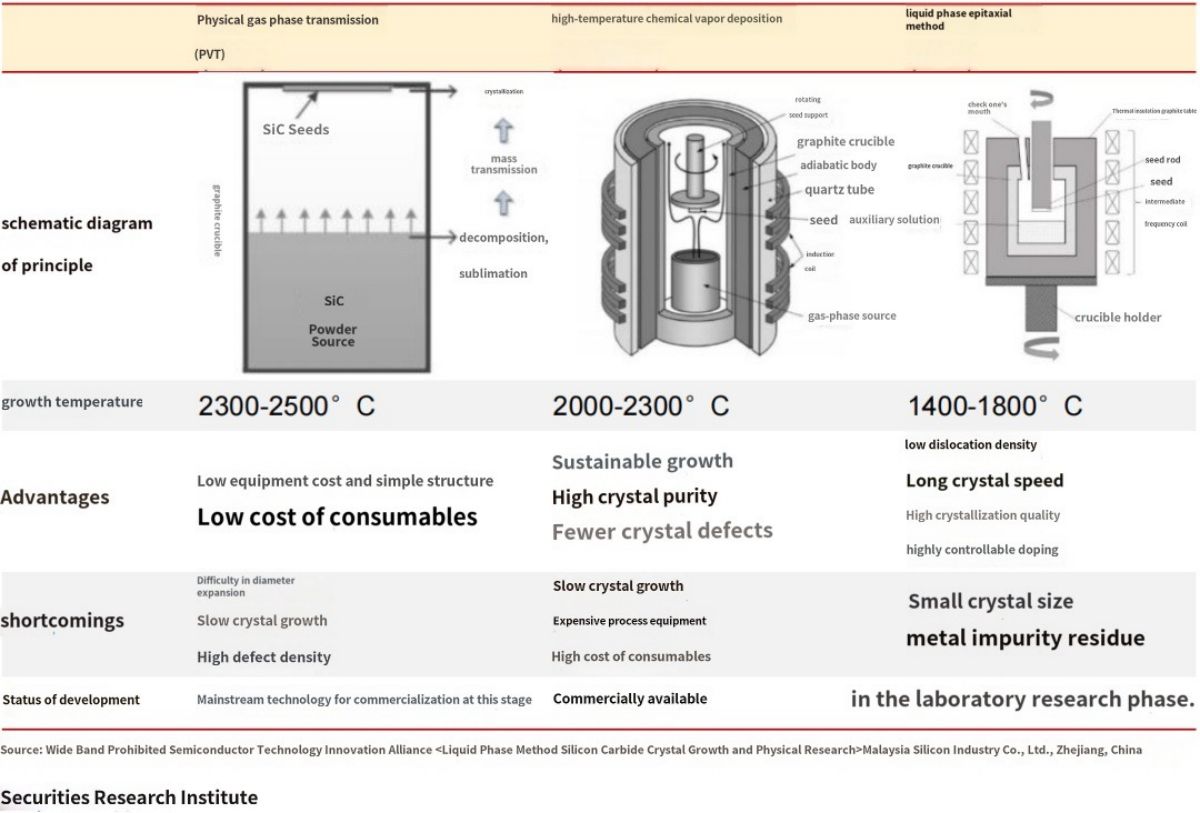

Crystal kev loj hlob yog cov txheej txheem tseem ceeb ntawm silicon carbide substrate manufacturing, uas txiav txim siab cov khoom hluav taws xob ntawm silicon carbide substrate.Tam sim no, cov txheej txheem tseem ceeb rau kev loj hlob siv lead ua yog lub cev vapor hloov pauv (PVT), kub kub tshuaj vapor deposition (HT-CVD) thiab kua theem epitaxy (LPE).Ntawm lawv, PVT txoj kev yog txoj hauv kev tseem ceeb rau kev lag luam kev loj hlob ntawm SiC substrate tam sim no, nrog rau kev ua haujlwm siab tshaj plaws thiab siv dav hauv engineering.

Kev npaj ntawm SiC substrate yog qhov nyuaj, ua rau nws tus nqi siab

Kev tswj qhov kub thiab txias yog qhov nyuaj: Si siv lead ua qws loj hlob tsuas yog xav tau 1500 ℃, thaum SiC siv lead ua pas nrig yuav tsum tau loj hlob ntawm qhov kub siab tshaj 2000 ℃, thiab muaj ntau tshaj 250 SiC isomers, tab sis lub ntsiab 4H-SiC ib leeg siv lead ua qauv rau kev tsim cov khoom siv hluav taws xob, yog tias tsis muaj kev tswj xyuas meej, yuav tau txais lwm cov qauv siv lead ua.Tsis tas li ntawd, qhov kub gradient nyob rau hauv lub crucible txiav txim siab tus nqi ntawm SiC sublimation hloov mus rau qhov chaw thiab kev loj hlob hom ntawm gaseous atoms ntawm lub crystal interface, uas cuam tshuam rau cov siv lead ua kev loj hlob tus nqi thiab siv lead ua zoo, yog li nws yog tsim nyog los tsim ib tug systematic kub teb. tswj technology.Piv nrog rau Si cov ntaub ntawv, qhov sib txawv ntawm SiC ntau lawm kuj yog nyob rau hauv cov txheej txheem kub xws li kub ion implantation, kub oxidation, kub ua kom kub, thiab cov txheej txheem nyuaj daim npog qhov ncauj yuav tsum tau los ntawm cov txheej txheem kub.

Kev loj hlob qeeb qeeb: qhov kev loj hlob ntawm Si siv lead ua pas nrig tuaj yeem ncav cuag 30 ~ 150mm / h, thiab cov khoom ntawm 1-3m silicon siv lead ua pas nrig tsuas yog siv li 1 hnub;SiC siv lead ua pas nrig nrog PVT txoj kev ua piv txwv, qhov kev loj hlob yog li ntawm 0.2-0.4mm / h, 7 hnub kom loj hlob tsawg dua 3-6cm, qhov kev loj hlob tsawg dua 1% ntawm cov khoom siv silicon, lub peev xwm ntau lawm yog qhov tsis tshua muaj siab. txwv.

Cov khoom lag luam siab tsis zoo thiab tsis tshua muaj txiaj ntsig: cov ntsiab lus tseem ceeb ntawm SiC substrate suav nrog microtubule ntom ntom, dislocation ceev, resistivity, warpage, nto roughness, thiab lwm yam. thaum tswj parameter indexes.

Cov khoom muaj siab hardness, siab brittleness, ntev txiav lub sij hawm thiab siab hnav: SiC Mohs hardness ntawm 9.25 yog thib ob xwb pob zeb diamond, uas ua rau ib tug tseem ceeb nce nyob rau hauv qhov nyuaj ntawm txiav, sib tsoo thiab polishing, thiab nws yuav siv sij hawm li ntawm 120 teev mus Txiav 35-40 pieces ntawm 3 cm tuab ingot.Tsis tas li ntawd, vim lub siab brittleness ntawm SiC, wafer ua hnav yuav ntau dua, thiab cov zis piv tsuas yog kwv yees li 60%.

Txoj kev loj hlob: Loj nce + nqi txo

Lub ntiaj teb SiC kev ua lag luam 6-nti ntim cov kab ntau lawm yog maturing, thiab cov tuam txhab ua lag luam tau nkag mus rau 8-nti ua lag luam.Kev txhim kho hauv tsev yog qhov tseem ceeb ntawm 6 ntiv tes.Tam sim no, txawm hais tias feem ntau cov tuam txhab lag luam tseem tab tom ua raws li 4-nti cov kab ntau lawm, tab sis kev lag luam tau maj mam nthuav mus rau 6-nti, nrog rau kev loj hlob ntawm 6-nti cov cuab yeej txhawb nqa technology, domestic SiC substrate technology kuj maj mam txhim kho kev lag luam ntawm nplai ntawm cov kab loj loj yuav raug cuam tshuam, thiab tam sim no domestic 6-nti loj ntau lawm lub sij hawm sib txawv tau nqaim mus rau 7 xyoo.Qhov loj wafer loj tuaj yeem ua rau muaj qhov nce ntawm cov chips ib leeg, txhim kho cov txiaj ntsig ntawm cov khoom lag luam, thiab txo qhov feem ntawm ntug chips, thiab cov nqi ntawm kev tshawb fawb thiab kev loj hlob thiab cov txiaj ntsig poob yuav raug tswj xyuas ntawm li 7%, yog li txhim kho wafer. kev siv.

Tseem muaj ntau yam teeb meem hauv kev tsim khoom siv

Kev lag luam ntawm SiC diode tau maj mam txhim kho, tam sim no, ntau lub tuam txhab tsim khoom hauv tsev tau tsim SiC SBD cov khoom lag luam, nruab nrab thiab siab voltage SiC SBD cov khoom muaj kev ruaj ntseg zoo, hauv tsheb OBC, kev siv SiC SBD + SI IGBT kom ua tiav ruaj khov. tam sim no ceev.Tam sim no, tsis muaj teeb meem hauv kev tsim patent ntawm SiC SBD cov khoom hauv Suav teb, thiab qhov sib txawv nrog cov teb chaws txawv teb chaws yog me me.

SiC MOS tseem muaj ntau yam teeb meem, tseem muaj qhov sib txawv ntawm SiC MOS thiab cov chaw tsim khoom txawv teb chaws, thiab cov chaw tsim khoom lag luam tseem tab tom tsim.Tam sim no, ST, Infineon, Rohm thiab lwm yam 600-1700V SiC MOS tau ua tiav ntau lawm thiab kos npe thiab xa nrog ntau qhov kev lag luam, thaum tam sim no domestic SiC MOS tsim tau ua tiav, ntau tus tsim tsim ua haujlwm nrog fabs ntawm wafer ntws theem, thiab tom qab ntawd cov neeg siv khoom pov thawj tseem xav tau qee lub sijhawm, yog li tseem muaj sijhawm ntev los ntawm kev lag luam loj.

Tam sim no, cov qauv kev npaj yog qhov kev xaiv tseem ceeb, thiab hom trench yog dav siv nyob rau hauv high-pressure teb yav tom ntej.Planar qauv SiC MOS cov tuam txhab muaj ntau, cov qauv qauv tsis yooj yim los tsim cov teeb meem kev puas tsuaj hauv zos piv nrog cov zawj, cuam tshuam rau kev ruaj ntseg ntawm kev ua haujlwm, hauv kev ua lag luam hauv qab 1200V muaj ntau yam ntawm daim ntawv thov tus nqi, thiab cov qauv qauv kuj tseem muaj. yooj yim nyob rau hauv manufacturing kawg, kom tau raws li manufacturability thiab tus nqi tswj ob yam.Cov cuab yeej zawv zawg muaj qhov zoo ntawm qhov tsis tshua muaj kab mob parasitic inductance, hloov pauv ceev ceev, poob qis thiab kev ua haujlwm siab.

2--SiC wafer xov xwm

Silicon carbide kev lag luam ntau lawm thiab kev muag khoom loj hlob, xyuam xim rau cov qauv kev tsis sib xws ntawm cov khoom siv thiab kev thov

Nrog rau kev loj hlob sai ntawm kev lag luam kev xav tau rau cov khoom siv hluav taws xob ntau zaus thiab lub zog hluav taws xob siab, lub cev txwv lub cev ntawm cov khoom siv silicon-based semiconductor tau maj mam ua qhov tseem ceeb, thiab cov khoom siv semiconductor thib peb uas sawv cev los ntawm silicon carbide (SiC) tau maj mam. ua industrialized.Los ntawm cov ntaub ntawv kev ua tau zoo ntawm qhov pom, silicon carbide muaj 3 npaug ntawm qhov sib txawv ntawm cov khoom siv silicon, 10 npaug ntawm qhov tseem ceeb ntawm lub zog hluav taws xob, 3 npaug ntawm thermal conductivity, yog li silicon carbide fais fab khoom siv yog tsim rau kev siv ntau zaus, kev kub siab, qhov kub thiab txias thiab lwm yam kev siv, pab txhim kho kev ua tau zoo thiab lub zog ntom ntom ntawm lub zog hluav taws xob.

Tam sim no, SiC diodes thiab SiC MOSFETs tau maj mam txav mus rau hauv kev ua lag luam, thiab muaj cov khoom lag luam paub tab ntau dua, ntawm cov SiC diodes tau siv dav siv los ntawm silicon-based diodes hauv qee qhov chaw vim tias lawv tsis muaj qhov zoo ntawm cov nqi rov qab;SiC MOSFET tseem maj mam siv hauv tsheb, lub zog cia, them pawg, photovoltaic thiab lwm yam haujlwm;Hauv kev ua haujlwm ntawm kev siv tsheb, cov qauv ntawm kev hloov pauv tau dhau los ua qhov tseem ceeb, qhov kev ua tau zoo ntawm SiC yuav tsum tau vam khom cov txheej txheem ntim khoom kom ua tiav, technically nrog cov laus laus lub plhaub sealing raws li lub ntsiab, lub neej yav tom ntej lossis rau kev tsim cov yas sealing. , nws qhov kev tsim kho tus yam ntxwv yog tsim nyog rau SiC modules.

Silicon carbide tus nqi poob qis lossis dhau qhov kev xav

Daim ntawv thov ntawm silicon carbide cov cuab yeej tsuas yog txwv los ntawm tus nqi siab, tus nqi ntawm SiC MOSFET nyob rau hauv tib theem yog 4 npaug siab dua li ntawm Si raws li IGBT, qhov no yog vim cov txheej txheem ntawm silicon carbide yog complex, nyob rau hauv uas txoj kev loj hlob ib leeg siv lead ua thiab epitaxial tsis yog tsuas yog hnyav rau ntawm ib puag ncig, tab sis kuj yog qhov kev loj hlob qeeb, thiab ib qho siv lead ua ua rau hauv cov substrate yuav tsum dhau los ntawm kev txiav thiab polishing.Raws li nws tus kheej cov yam ntxwv ntawm cov khoom siv thiab cov cuab yeej ua tsis tiav, cov txiaj ntsig ntawm cov khoom siv hauv tsev yog tsawg dua 50%, thiab ntau yam ua rau cov khoom siv hluav taws xob siab thiab cov nqi epitaxial.

Txawm li cas los xij, tus nqi ntawm cov khoom siv silicon carbide thiab cov khoom siv silicon yog diametrically opposite, substrate thiab epitaxial nqi ntawm cov channel pem hauv ntej account rau 47% thiab 23% ntawm tag nrho cov cuab yeej feem, tag nrho txog 70%, cov cuab yeej tsim, tsim. thiab kev sib txuas ntawm cov channel rov qab rau tsuas yog 30%, tus nqi tsim khoom ntawm silicon-raws li cov khoom siv feem ntau yog tsom rau hauv kev tsim cov wafer ntawm cov channel rov qab txog 50%, thiab cov nqi substrate tsuas yog 7%.Qhov tshwm sim ntawm tus nqi ntawm silicon carbide kev lag luam saw upside down txhais tau hais tias upstream substrate epitaxy manufacturers muaj cov tub ntxhais txoj cai hais lus, uas yog tus yuam sij rau lub layout ntawm domestic thiab txawv teb chaws lag luam.

Los ntawm qhov kev xav tau ntawm kev ua lag luam, txo tus nqi ntawm silicon carbide, ntxiv rau kev txhim kho cov silicon carbide ntev siv lead ua thiab slicing txheej txheem, yog kom nthuav dav wafer loj, uas kuj yog txoj kev loj hlob ntawm semiconductor txoj kev loj hlob yav dhau los, Wolfspeed cov ntaub ntawv qhia tias cov silicon carbide substrate upgrade ntawm 6 ntiv mus rau 8 ntiv tes, tsim nyog nti ntau lawm tuaj yeem nce 80% -90%, thiab pab txhim kho cov txiaj ntsig.tuaj yeem txo cov nqi sib xyaw ua ke los ntawm 50%.

2023 yog lub npe hu ua "8-nti SiC thawj xyoo", xyoo no, cov tuam txhab lag luam hauv tsev thiab txawv teb chaws silicon carbide tau nrawm cov txheej txheem ntawm 8-nti silicon carbide, xws li Wolfspeed vwm peev ntawm 14.55 billion US dollars rau silicon carbide ntau lawm expansion, ib qho tseem ceeb ntawm uas yog kev tsim kho ntawm 8-nti SiC substrate manufacturing cog, Kom paub meej cov khoom siv yav tom ntej ntawm 200 mm SiC liab qab rau ntau lub tuam txhab;Hauv Tianyue Advanced thiab Tianke Heda kuj tau kos npe rau daim ntawv cog lus ntev nrog Infineon los muab 8-nti silicon carbide substrates rau yav tom ntej.

Pib los ntawm lub xyoo no, silicon carbide yuav nrawm ntawm 6 ntiv mus rau 8 ntiv tes, Wolfspeed cia siab tias los ntawm 2024, cov nqi nti ntawm 8 nti substrate piv rau cov nqi nti ntawm 6 nti substrate hauv 2022 yuav raug txo los ntawm ntau dua 60%. , thiab tus nqi poob yuav ntxiv qhib daim ntawv thov kev lag luam, Ji Bond Consulting cov ntaub ntawv tshawb fawb tau taw qhia.Kev lag luam tam sim no ntawm 8-nti cov khoom lag luam tsawg dua 2%, thiab kev lag luam sib faib yuav tsum loj hlob mus txog 15% los ntawm 2026.

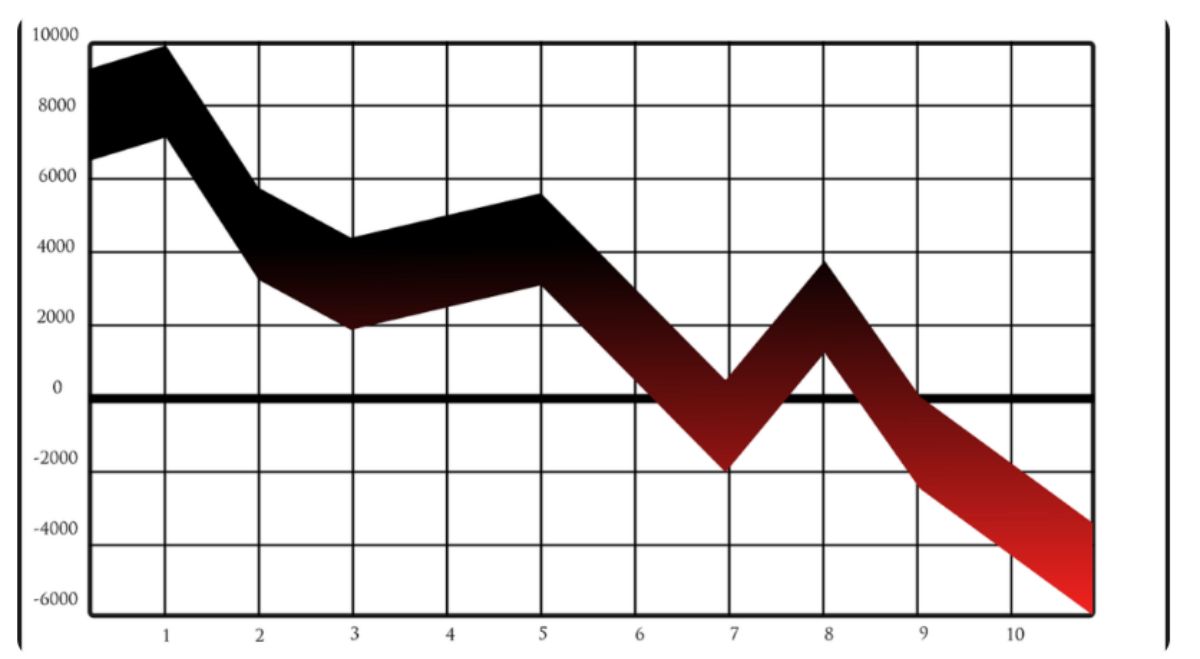

Qhov tseeb, tus nqi poob qis ntawm tus nqi ntawm silicon carbide substrate yuav dhau ntau tus neeg txoj kev xav, kev lag luam tam sim no ntawm 6-nti substrate yog 4000-5000 yuan / thooj, piv nrog rau thaum pib ntawm lub xyoo tau poob ntau, yog cia siab tias yuav poob qis dua 4000 yuan rau xyoo tom ntej, nws yog ib qho tsim nyog sau cia tias qee cov tuam txhab lag luam txhawm rau kom tau txais thawj lub lag luam, tau txo tus nqi muag khoom rau cov nqi hauv qab no, Qhib cov qauv ntawm cov nqi tsov rog, feem ntau yog concentrated hauv silicon carbide substrate. cov khoom lag luam tau txais txiaj ntsig zoo nyob rau hauv qhov tsis tshua muaj hluav taws xob, cov tuam txhab tsim khoom hauv tsev thiab txawv teb chaws tau nthuav dav ntau lawm, lossis cia cov silicon carbide substrate oversupply theem ua ntej tshaj li qhov xav tau.

Post lub sij hawm: Jan-19-2024