Raws li ib tug thib peb tiam semiconductor substrate khoom,silicon carbide (SiC)ib leeg siv lead ua muaj dav daim ntawv thov kev cia siab nyob rau hauv kev tsim cov high-frequency thiab high-power electronics. Kev siv thev naus laus zis ntawm SiC ua lub luag haujlwm txiav txim siab hauv kev tsim cov khoom siv zoo substrate. Tsab ntawv xov xwm no qhia txog lub xeev tam sim no ntawm kev tshawb fawb ntawm SiC ua cov thev naus laus zis hauv Suav teb thiab txawv teb chaws, tshuaj xyuas thiab sib piv cov txheej txheem ntawm kev txiav, sib tsoo, thiab polishing txheej txheem, nrog rau cov qauv ntawm wafer flatness thiab nto roughness. Nws kuj tau taw qhia txog cov teeb meem uas twb muaj lawm hauv SiC wafer ua thiab sib tham txog cov lus qhia kev txhim kho yav tom ntej.

Silicon carbide (SiC)wafers yog cov ntaub ntawv tseem ceeb rau cov khoom siv semiconductor thib peb thiab tuav qhov tseem ceeb thiab kev lag luam muaj peev xwm hauv kev lag luam xws li microelectronics, hluav taws xob hluav taws xob, thiab semiconductor teeb pom kev zoo. Vim qhov tsis tshua muaj siab hardness thiab tshuaj stability ntawmSiC ib leeg siv lead ua, tsoos semiconductor ua txoj kev tsis yog tag nrho haum rau lawv machining. Txawm hais tias ntau lub tuam txhab thoob ntiaj teb tau tshawb fawb ntau yam ntawm kev xav tau kev ua haujlwm ntawm SiC ib leeg siv lead ua, cov thev naus laus zis cuam tshuam tau khaws cia nruj me ntsis.

Nyob rau hauv xyoo tas los no, Tuam Tshoj tau nce kev siv zog hauv kev tsim SiC ib leeg siv lead ua cov ntaub ntawv thiab cov khoom siv. Txawm li cas los xij, kev nce qib ntawm SiC cov cuab yeej thev naus laus zis hauv lub tebchaws tam sim no raug txwv los ntawm kev txwv hauv kev ua cov thev naus laus zis thiab wafer zoo. Yog li ntawd, nws yog ib qho tseem ceeb rau Tuam Tshoj los txhim kho SiC kev muaj peev xwm los txhim kho qhov zoo ntawm SiC ib leeg siv lead ua substrates thiab ua tiav lawv cov kev siv tswv yim thiab ntau lawm.

Cov kauj ruam ua haujlwm tseem ceeb suav nrog: txiav → ntxhib sib tsoo → zoo sib tsoo → ntxhib polishing (mechanical polishing) → polishing zoo (tshuaj kho tshuab polishing, CMP) → tshuaj xyuas.

| Kauj ruam | SiC Wafer Processing | Tsob Ntoo Semiconductor Ib-Crystal Material Processing |

| Txiav | Siv ntau txoj hlua sawing tshuab los hlais SiC ingots rau hauv nyias wafers | Feem ntau siv cov txheej txheem sab hauv los yog sab nraud-inch hniav txiav |

| Sib tsoo | Muab faib rau hauv ntxhib thiab zoo sib tsoo kom tshem tawm cov cim pom thiab kev puas tsuaj los ntawm kev txiav | Txoj kev sib tsoo tej zaum yuav txawv, tab sis lub hom phiaj yog tib yam |

| Polishing | Xws li ntxhib thiab ultra-precision polishing siv txhua yam thiab tshuaj lom neeg polishing (CMP) | Feem ntau suav nrog tshuaj kho tshuab polishing (CMP), txawm tias cov kauj ruam tshwj xeeb yuav txawv |

Txiav ntawm SiC Ib Leeg Crystals

Hauv kev ua ntawmSiC ib leeg siv lead ua, txiav yog thawj zaug thiab cov kauj ruam tseem ceeb heev. Lub wafer lub hneev, warp, thiab tag nrho cov thickness variation (TTV) los ntawm cov txheej txheem txiav txiav txim siab qhov zoo thiab kev ua tau zoo ntawm kev sib tsoo thiab polishing tom ntej.

Cov cuab yeej txiav tuaj yeem muab faib los ntawm cov duab rau hauv pob zeb diamond puab txoj kab uas hla (ID) saws, txheej kab (OD) saws, band saws, thiab hlau saws. Hlau saws, nyob rau hauv lem, muaj peev xwm muab cais los ntawm lawv cov lus tsa suab rau hauv reciprocating thiab voj (kawg) hlau tshuab. Raws li kev txiav cov txheej txheem ntawm abrasive, hlau pom slicing cov tswv yim tuaj yeem muab faib ua ob hom: dawb abrasive hlau sawing thiab ruaj abrasive pob zeb diamond hlau sawing.

1.1 Txoj kev txiav tsoos

Kev txiav qhov tob ntawm sab nraud (OD) saws yog txwv los ntawm txoj kab uas hla ntawm cov hniav. Thaum lub sij hawm txiav cov txheej txheem, cov hniav tuaj yeem ua rau kev vibration thiab sib txawv, ua rau muaj suab nrov thiab tsis zoo. Sab hauv txoj kab uas hla (ID) saws siv pob zeb diamond abrasives ntawm lub puab ncig ntawm cov hniav raws li cov txiav ntug. Cov hniav no tuaj yeem ua nyias li 0.2 hli. Thaum lub sij hawm slicing, tus ID hniav rotates ntawm kev kub ceev thaum cov khoom yuav tsum tau txiav txav radially txheeb ze rau cov hniav qhov chaw, ua tiav slicing los ntawm no txheeb ze tsab ntawv tsa suab.

Pob zeb diamond band saws yuav tsum tau nres thiab thim rov qab, thiab kev txiav ceev yog tsawg heev - feem ntau tsis tshaj 2 m / s. Lawv kuj raug kev txom nyem los ntawm cov khoom siv tseem ceeb thiab cov nqi kho mob siab. Vim qhov dav ntawm cov saw hniav, lub vojvoog txiav tsis tuaj yeem me me dhau, thiab txiav txiav ntau yam tsis tuaj yeem ua tau. Cov cuab yeej sawing tsoos no raug txwv los ntawm kev nruj ntawm lub hauv paus thiab tsis tuaj yeem ua kom nkhaus txiav los yog muaj kev txwv tsis pub tig radii. Lawv tsuas muaj peev xwm ntawm kev txiav ncaj, tsim cov kerfs dav, muaj tus nqi qis, thiab yog li tsis tsim nyog rau kev txiav.SiC siv lead ua.

1.2 Dawb Abrasive Hlau Pom Ntau Hlau Txiav

Cov txheej txheem dawb abrasive hlau pom slicing siv cov kev txav ceev ntawm cov hlau los nqa slurry rau hauv kerf, ua kom tshem tawm cov khoom. Nws feem ntau siv cov qauv reciprocating thiab tam sim no yog ib txoj kev paub tab thiab siv dav rau kev ua tau zoo ntawm ntau lub wafer txiav ntawm ib leeg-crystal silicon. Txawm li cas los xij, nws daim ntawv thov hauv SiC txiav tau raug kawm tsawg dua.

Dawb abrasive hlau saws tuaj yeem ua cov wafers nrog thicknesses tsawg dua 300 μm. Lawv muab qis kerf poob, tsis tshua ua rau chipping, thiab ua rau qhov zoo ntawm qhov chaw zoo. Txawm li cas los xij, vim yog cov khoom siv tshem tawm-raws li dov thiab indentation ntawm abrasives-lub wafer nto yuav tsim kev ntxhov siab tseem ceeb, microcracks, thiab kev puas tsuaj tob. Qhov no ua rau wafer warping, ua rau nws nyuaj rau kev tswj xyuas qhov tseeb ntawm qhov profile, thiab ua rau kom cov load ntawm cov kauj ruam tom ntej.

Qhov kev ua tau zoo yog cuam tshuam los ntawm slurry; Nws yog ib qho tsim nyog los tswj xyuas qhov ntse ntawm cov abrasives thiab qhov concentration ntawm slurry. Kev kho slurry thiab rov ua dua yog kim. Thaum txiav cov ingots loj, cov abrasives nyuaj nkag mus tob thiab ntev kerfs. Nyob rau hauv tib lub abrasive grain loj, lub kerf poob yog ntau dua li ntawm tsau-abrasive hlau saws.

1.3 Tsau Abrasive Pob Zeb Diamond Hlau Pom Ntau Hlau Txiav

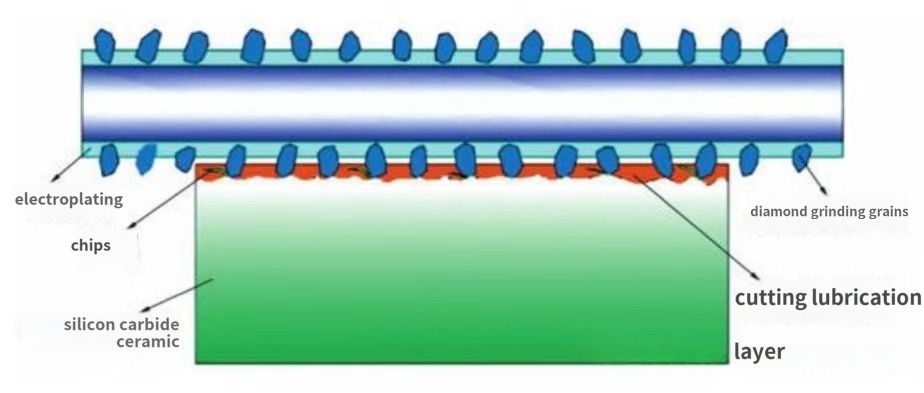

Tsau abrasive pob zeb diamond hlau saws feem ntau yog ua los ntawm embedding pob zeb diamond hais mus rau ib tug hlau hlau substrate los ntawm electroplating, sintering, los yog resin bonding txoj kev. Electroplated pob zeb diamond hlau saws muaj qhov zoo xws li cov pob zeb nqaim, cov hlais zoo dua, kev ua haujlwm siab dua, qis qis, thiab muaj peev xwm txiav cov ntaub ntawv hardness siab.

Lub reciprocating electroplated pob zeb diamond hlau pom yog tam sim no feem ntau siv txoj kev txiav SiC. Daim duab 1 (tsis muaj nyob ntawm no) qhia txog qhov flatness ntawm SiC wafers txiav siv cov txheej txheem no. Raws li kev txiav ua tiav, wafer warpage nce. Qhov no yog vim qhov chaw sib cuag ntawm cov hlau thiab cov khoom siv nce ntxiv thaum cov xaim txav mus rau hauv qab, ua rau muaj kev tiv thaiv thiab xaim kev co. Thaum cov hlau ncav cuag lub wafer lub siab tshaj plaws txoj kab uas hla, lub vibration yog nyob rau hauv nws lub ncov, ua rau lub siab tshaj plaws warpage.

Nyob rau theem tom ntej ntawm kev txiav, vim yog cov xaim ua kom nrawm, ruaj khov-ceev txav, deceleration, nres, thiab thim rov qab, nrog rau cov teeb meem hauv kev tshem cov khib nyiab nrog lub coolant, qhov zoo ntawm lub wafer deteriorates. Hlau thim rov qab thiab ceev hloov pauv, nrog rau cov pob zeb diamond loj ntawm cov xaim, yog thawj qhov ua rau khawb qhov chaw.

1.4 Cold Separation Technology

Kev sib cais txias ntawm SiC ib leeg muaju yog cov txheej txheem tshiab hauv kev ua cov khoom siv semiconductor thib peb. Nyob rau hauv xyoo tas los no, nws tau nyiam cov xim tseem ceeb vim nws cov txiaj ntsig tseem ceeb hauv kev txhim kho cov txiaj ntsig thiab txo cov khoom poob. Cov thev naus laus zis tuaj yeem txheeb xyuas los ntawm peb yam: kev ua haujlwm hauv paus ntsiab lus, cov txheej txheem ntws, thiab cov txiaj ntsig tseem ceeb.

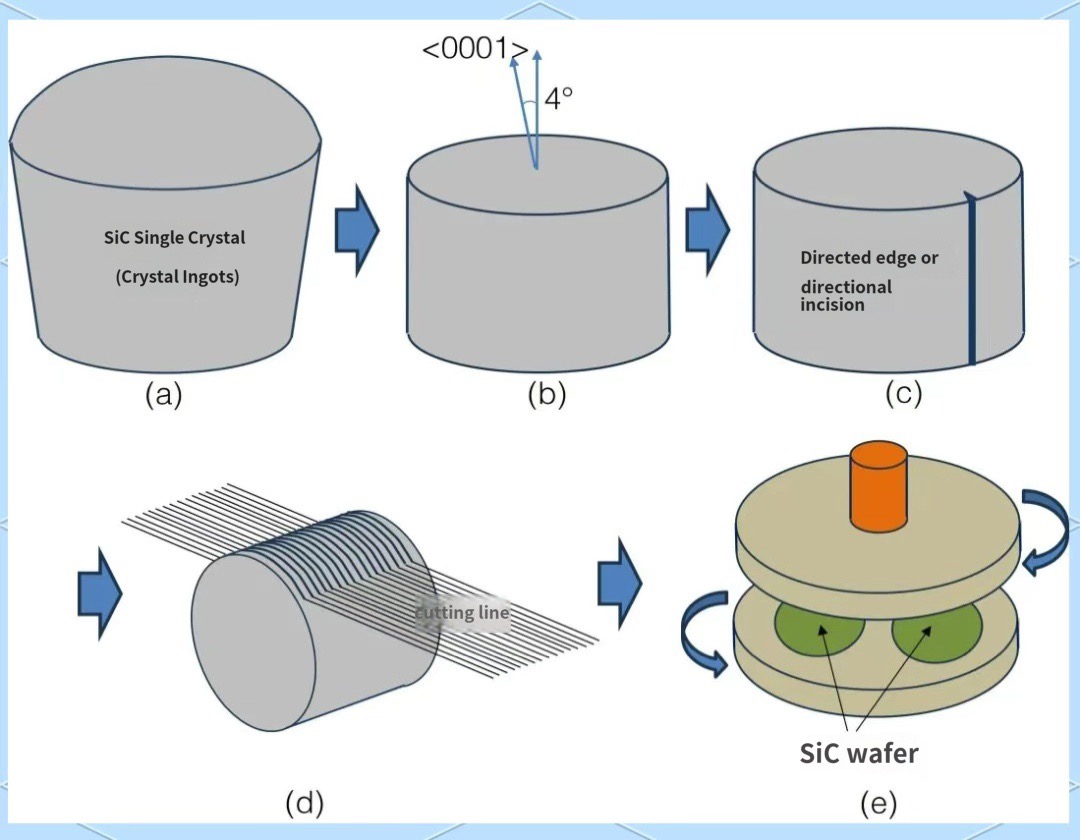

Crystal Orientation Determination thiab Outer Diameter Sib Tsoo: Ua ntej ua tiav, siv lead ua orientation ntawm SiC ingot yuav tsum tau txiav txim siab. Lub ingot yog tom qab ntawd zoo li tus qauv cylindrical (feem ntau hu ua SiC puck) ntawm sab nraud sib tsoo. Cov kauj ruam no nteg lub hauv paus rau kev taw qhia tom ntej txiav thiab txiav.

Multi-Wire Cutting: Txoj kev no siv cov khoom abrasive ua ke nrog txiav cov xov hlau los txiav cov cylindrical ingot. Txawm li cas los xij, nws raug kev txom nyem los ntawm qhov tseem ceeb ntawm kerf poob thiab teeb meem ntawm qhov tsis sib xws.

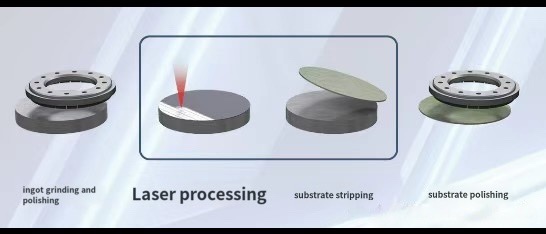

Laser Txiav Technology: Lub laser yog siv los tsim cov txheej txheem hloov hauv cov siv lead ua, los ntawm cov hlais nyias tuaj yeem raug tshem tawm. Txoj hauv kev no txo cov khoom poob thiab txhim kho kev ua tau zoo, ua rau nws muaj kev cog lus tshiab rau SiC wafer txiav.

Txiav txheej txheem optimization

Tsau Abrasive Multi-Wire Cutting: Qhov no yog tam sim no cov thev naus laus zis thev naus laus zis, zoo tsim nyog rau cov yam ntxwv siab tawv ntawm SiC.

Electrical Discharge Machining (EDM) thiab Cold Separation Technology: Cov txheej txheem no muab ntau txoj kev daws teeb meem raws li cov cai tshwj xeeb.

Polishing txheej txheem: Nws yog ib qho tseem ceeb kom sib npaug ntawm cov khoom tshem tawm tus nqi thiab kev puas tsuaj saum npoo. Chemical Mechanical Polishing (CMP) yog ua haujlwm los txhim kho qhov sib xws.

Kev Saib Xyuas Lub Sijhawm Tiag: Cov thev naus laus zis tshuaj xyuas online tau qhia los saib xyuas qhov roughness ntawm lub sijhawm.

Laser Slicing: Cov txheej txheem no txo qis kerf poob thiab ua kom luv luv, txawm hais tias thaj chaw thermal cuam tshuam tseem yog qhov nyuaj.

Hybrid Processing Technologies: Kev sib xyaw ua ke ntawm cov tshuab thiab tshuaj lom neeg ua kom muaj kev ua haujlwm zoo.

Cov tshuab no twb tau ua tiav daim ntawv thov kev lag luam. Infineon, piv txwv li, tau txais SILTECTRA thiab tam sim no tuav cov patents tseem ceeb txhawb nqa ntau lawm ntawm 8-nti wafers. Hauv Suav teb, cov tuam txhab xws li Delong Laser tau ua tiav cov txiaj ntsig ntawm 30 wafers ib qho khoom siv rau 6-nti wafer ua, sawv cev rau 40% kev txhim kho ntawm cov txheej txheem ib txwm muaj.

Raws li kev tsim khoom siv hauv tsev nrawm dua, cov thev naus laus zis no xav kom dhau los ua cov kev daws teeb meem tseem ceeb rau SiC substrate ua. Nrog rau txoj kab uas hla ntawm cov khoom siv semiconductor, cov kev txiav tsoos tau dhau los lawm. Ntawm cov kev xaiv tam sim no, reciprocating pob zeb diamond hlau pom thev naus laus zis qhia tau hais tias feem ntau cov ntawv thov kev cia siab. Laser txiav, raws li cov txheej txheem tawm tshiab, muaj qhov zoo tseem ceeb thiab cia siab tias yuav dhau los ua thawj txoj kev txiav yav tom ntej.

2,SiC Ib Leeg Sib Tsoo

Raws li tus neeg sawv cev ntawm tiam thib peb semiconductors, silicon carbide (SiC) muaj txiaj ntsig zoo vim nws qhov dav bandgap, siab tawg hluav taws xob teb, siab saturation electron drift tshaj tawm, thiab thermal conductivity zoo heev. Cov khoom no ua rau SiC tshwj xeeb tshaj yog muaj txiaj ntsig zoo hauv kev siv hluav taws xob siab (xws li, 1200V ib puag ncig). Kev siv thev naus laus zis rau SiC substrates yog qhov tseem ceeb ntawm kev tsim khoom siv. Qhov saum npoo zoo thiab qhov tseeb ntawm lub substrate ncaj qha cuam tshuam rau qhov zoo ntawm cov txheej txheem epitaxial thiab kev ua haujlwm ntawm cov cuab yeej kawg.

Lub hom phiaj tseem ceeb ntawm cov txheej txheem sib tsoo yog tshem tawm cov cim saum npoo thiab cov txheej txheem kev puas tsuaj tshwm sim thaum lub sij hawm slicing, thiab kho deformation induced los ntawm cov txheej txheem txiav. Muab SiC qhov nyuaj siab heev, kev sib tsoo yuav tsum siv cov tawv abrasives xws li boron carbide lossis pob zeb diamond. Kev sib tsoo feem ntau yog muab faib ua ntxhib sib tsoo thiab sib tsoo zoo.

2.1 Coarse thiab zoo sib tsoo

Sib tsoo tuaj yeem categorized raws li abrasive particle loj:

Coarse Sib Tsoo: Siv cov abrasives loj dua los tshem tawm cov cim thiab cov txheej txheem puas tsuaj tshwm sim thaum lub sij hawm txiav, txhim kho kev ua haujlwm.

Fine Grinding: Siv cov tshuaj txhuam hniav kom tshem tawm cov txheej txheem puas sab laug los ntawm kev sib tsoo ntxhib, txo qhov roughness, thiab txhim kho qhov zoo.

Ntau lub tuam txhab SiC hauv tsev siv cov txheej txheem ntau lawm. Ib txoj hauv kev yog ob sab sib tsoo siv lub phaj hlau cam khwb cia thiab monocrystalline pob zeb diamond slurry. Cov txheej txheem no zoo tshem tawm cov txheej txheem kev puas tsuaj sab laug los ntawm cov hlau sawing, kho cov duab wafer, thiab txo TTV (Tag nrho Thickness Variation), Hneev, thiab Warp. Cov khoom tshem tawm tus nqi yog ruaj khov, feem ntau ncav cuag 0.8-1.2 μm / min. Txawm li cas los xij, qhov tshwm sim wafer nto yog matte nrog roughness siab - feem ntau nyob ib ncig ntawm 50 nm - uas ua rau muaj kev xav tau ntau dua ntawm cov kauj ruam tom ntej polishing.

2.2 Ib sab sib tsoo

Ib sab sib tsoo txheej txheem tsuas yog ib sab ntawm wafer ib zaug. Thaum lub sij hawm txoj kev no, lub wafer yog wax-mounted rau ntawm steel phaj. Nyob rau hauv kev siv lub siab, lub substrate undergoes me ntsis deformation, thiab saum npoo yog flattened. Tom qab sib tsoo, qhov chaw qis yog leveled. Thaum lub siab raug tshem tawm, qhov saum npoo zoo li rov qab los rau nws qhov qub, uas tseem cuam tshuam rau hauv av qis dua-ua rau ob sab rau warp thiab degrade hauv flatness.

Ntxiv mus, lub phaj sib tsoo tuaj yeem ua concave hauv lub sijhawm luv luv, ua rau lub wafer ua convex. Yuav kom tswj tau qhov flatness ntawm lub phaj, yuav tsum tau hnav khaub ncaws ntau zaus. Vim qhov tsis tshua muaj txiaj ntsig thiab tsis zoo wafer flatness, kev sib tsoo ib leeg tsis haum rau ntau lawm.

Feem ntau, #8000 sib tsoo log yog siv rau kev sib tsoo zoo. Hauv Nyij Pooj, cov txheej txheem no kuj paub tab thiab txawm siv # 30000 polishing log. Qhov no tso cai rau qhov roughness ntawm cov txheej txheem wafers mus txog qis dua 2 nm, ua rau cov wafers npaj rau qhov kawg CMP (Chemical Mechanical Polishing) yam tsis muaj kev ua ntxiv.

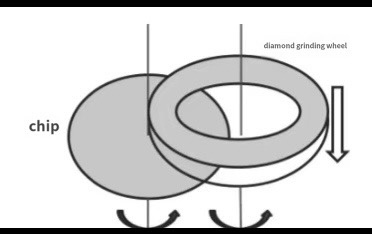

2.3 Tib-Sided Thinning Technology

Pob zeb diamond Single-Sided Thinning Technology yog ib txoj kev tshiab ntawm kev sib tsoo ib leeg. Raws li tau piav qhia hauv daim duab 5 (tsis qhia ntawm no), cov txheej txheem siv lub pob zeb diamond sib tsoo phaj. Lub wafer yog tsau ntawm lub tshuab nqus tsev adsorption, thaum lub wafer thiab pob zeb diamond sib tsoo log tig ib txhij. Lub log sib tsoo maj mam txav mus rau hauv qab kom nyias lub wafer mus rau lub hom phiaj tuab. Tom qab ib sab ua tiav, lub wafer yog flipped mus rau lwm sab.

Tom qab thinning, 100 hli wafer tuaj yeem ua tiav:

Qhov siab <5 μm

TVV < 2 μm

Nto roughness <1 nm

Qhov no ib leeg-wafer ua txoj kev muaj kev ruaj ntseg siab, zoo sib xws, thiab cov khoom siv siab tshem tawm. Piv rau cov pa sib tsoo ob sab, cov txheej txheem no txhim kho kev sib tsoo ua haujlwm ntau dua 50%.

2.4 Ob tog sib tsoo

Kev sib tsoo ob sab siv ob qho tib si sab sauv thiab sab qis sib tsoo phaj rau tib lub sijhawm sib tsoo ob sab ntawm lub substrate, kom ntseeg tau zoo heev ntawm ob sab.

Thaum lub sij hawm tus txheej txheem, cov hlau sib tsoo thawj zaug siv siab rau cov ntsiab lus siab tshaj plaws ntawm lub workpiece, ua rau deformation thiab maj mam tshem tawm cov khoom ntawm cov ntsiab lus. Raws li qhov chaw siab yog leveled, lub siab ntawm lub substrate maj mam ua ntau yam, uas ua rau muaj kev sib txuam deformation thoob plaws tag nrho saum npoo. Qhov no tso cai rau ob qho tib si sab sauv thiab sab qis kom hauv av sib npaug. Thaum cov kev sib tsoo ua tiav thiab lub siab tso tawm, txhua feem ntawm lub substrate rov zoo li qub vim qhov sib npaug ntawm qhov nws tau ntsib. Qhov no ua rau tsawg kawg warping thiab zoo flatness.

Qhov saum npoo roughness ntawm wafer tom qab sib tsoo yog nyob ntawm qhov loj me me-cov khoom me me ua rau lub ntsej muag smoother. Thaum siv 5 μm abrasives rau ob sab sib tsoo, wafer flatness thiab thickness variation tuaj yeem tswj tau li ntawm 5 μm. Atomic Force Microscopy (AFM) kev ntsuas qhia pom qhov roughness (Rq) ntawm txog 100 nm, nrog kev sib tsoo qhov tob txog 380 nm sib sib zog nqus thiab pom cov kab kos los ntawm kev ua abrasive.

Ib txoj hauv kev zoo dua yog kev sib tsoo ob sab siv polyurethane ua npuas ncauj ua ke nrog polycrystalline pob zeb diamond slurry. Cov txheej txheem no tsim cov wafers nrog qhov tsawg ntawm qhov roughness, ua tiav Ra <3 nm, uas muaj txiaj ntsig zoo rau kev polishing tom ntej ntawm SiC substrates.

Txawm li cas los xij, khawb qhov chaw tseem yog qhov teeb meem tsis daws teeb meem. Tsis tas li ntawd, cov pob zeb diamond polycrystalline siv rau hauv cov txheej txheem no yog tsim los ntawm kev sib xyaw ua ke, uas yog kev sib tw, yields tsawg, thiab kim heev.

Polishing ntawm SiC Ib Leeg Crystals

Yuav kom ua tiav qhov zoo polished nto ntawm silicon carbide (SiC) wafers, polishing yuav tsum tau tshem tawm tag nrho cov sib tsoo pits thiab nanometer-scale deg undulations. Lub hom phiaj yog los tsim kom muaj qhov sib luag, tsis muaj qhov tsis xws luag, tsis muaj kev sib kis lossis degradation, tsis muaj kev puas tsuaj rau subsurface, thiab tsis muaj qhov seem ntawm qhov seem.

3.1 Mechanical Polishing thiab CMP ntawm SiC Wafers

Tom qab kev loj hlob ntawm SiC ib leeg siv lead ua ingot, deg defects tiv thaiv nws los ntawm kev siv ncaj qha rau kev loj hlob epitaxial. Yog li ntawd, yuav tsum tau ua ntxiv. Lub ingot yog thawj zaug zoo li tus qauv cylindrical daim ntawv los ntawm rounding, ces hlais rau hauv wafers siv hlau txiav, ua raws li crystallographic orientation pov thawj. Polishing yog ib kauj ruam tseem ceeb hauv kev txhim kho wafer zoo, hais txog qhov muaj peev xwm ntawm qhov chaw puas los ntawm kev loj hlob tsis xws luag thiab cov txheej txheem ua ntej.

Muaj plaub txoj hauv kev tseem ceeb rau tshem tawm cov khaubncaws sab nraud povtseg ntawm SiC:

Mechanical polishing: Yooj yim tab sis tawm khawb; haum rau thawj polishing.

Chemical Mechanical Polishing (CMP): Tshem tawm cov khawb ntawm cov tshuaj etching; haum rau precision polishing.

Hydrogen etching: Yuav tsum muaj cov cuab yeej siv, feem ntau siv hauv cov txheej txheem HTCVD.

Plasma-pab polishing: complex thiab tsis tshua siv.

Mechanical-tsuas polishing nyiam ua rau khawb, thaum tshuaj lom neeg tsuas yog polishing tuaj yeem ua rau tsis sib xws. CMP muab ob qho tib si zoo thiab muab cov kev daws teeb meem zoo, tus nqi zoo.

CMP Txoj Cai Ua Haujlwm

CMP ua haujlwm los ntawm kev tig lub wafer nyob rau hauv lub teeb siab tiv thaiv ib tug rotating polishing ncoo. Qhov kev txheeb ze no, ua ke nrog cov neeg kho tshuab abrasion los ntawm nano-sized abrasives hauv slurry thiab tshuaj lom neeg ua haujlwm ntawm cov neeg ua haujlwm reactive, ua tiav cov phiaj xwm saum npoo.

Cov khoom siv tseem ceeb:

Polishing slurry: muaj cov abrasives thiab tshuaj reagents.

Polishing ncoo: Hnav qis thaum siv, txo qhov pore loj thiab slurry xa khoom efficiency. Kev hnav khaub ncaws tsis tu ncua, feem ntau yog siv lub pob zeb diamond dresser, yuav tsum tau ua kom rov qab roughness.

Txheej txheem CMP

Abrasive: 0.5 μm pob zeb diamond slurry

Lub hom phiaj nto roughness: ~ 0.7 nm

Tshuaj Mechanical Polishing:

Cov khoom siv polishing: AP-810 ib leeg-tog polisher

Siab: 200 g / cm2

Phaj ceev: 50 rpm

Ceramic tuav ceev: 38 rpm

Slurry muaj pes tsawg leeg:

SiO₂ (30 wt%, pH = 10.15)

0-70 wt% H₂O₂ (30 wt%, reagent qib)

Kho pH rau 8.5 siv 5 wt% KOH thiab 1 wt% HNO₃

Slurry txaus tus nqi: 3L / min, recirculated

Cov txheej txheem no zoo txhim kho SiC wafer zoo thiab ua tau raws li qhov yuav tsum tau ua rau cov txheej txheem qis.

Kev Sib Tw Hauv Kev Siv Tshuab Polishing

SiC, raws li qhov dav bandgap semiconductor, ua lub luag haujlwm tseem ceeb hauv kev lag luam hluav taws xob. Nrog rau cov khoom zoo ntawm lub cev thiab tshuaj lom neeg, SiC ib leeg siv lead ua yog tsim rau qhov chaw huab cua, xws li kub, siab zaus, siab zog, thiab hluav taws xob tsis kam. Txawm li cas los xij, nws qhov nyuaj thiab nkig ua rau muaj teeb meem loj rau kev sib tsoo thiab polishing.

Raws li cov tuam txhab lag luam thoob ntiaj teb hloov pauv ntawm 6-nti mus rau 8-nti wafers, cov teeb meem xws li tawg thiab wafer puas tsuaj thaum ua tiav tau dhau los ua qhov tseem ceeb, cuam tshuam rau cov txiaj ntsig. Hais txog kev cov nyom ntawm 8-nti SiC substrates yog tam sim no tus qauv tseem ceeb rau kev lag luam kev nce qib.

Hauv 8-nti era, SiC wafer ua tau ntsib ntau yam teeb meem:

wafer scaling yog tsim nyog los ua kom cov nti tso tawm ib batch, txo cov ntug poob, thiab txo cov nqi tsim khoom - tshwj xeeb tshaj yog tau txais kev thov nce hauv kev siv tsheb fais fab.

Thaum txoj kev loj hlob ntawm 8-nti SiC ib leeg muaj matured, cov txheej txheem rov qab zoo li kev sib tsoo thiab polishing tseem fim lub fwj, ua rau cov khoom qis (tsuas yog 40-50%).

Cov wafers loj dua muaj kev cuam tshuam ntau dua, ua rau muaj kev nyuaj ntawm kev tswj polishing kev ntxhov siab thiab tawm los sib xws.

Txawm hais tias lub thickness ntawm 8-nti wafers mus txog ntawm 6-nti wafers, lawv muaj kev puas tsuaj ntau dua thaum tuav vim kev ntxhov siab thiab kev sib hloov.

Txhawm rau txo cov kev ntxhov siab cuam tshuam, kev sib tsoo, thiab tawg, laser txiav yog siv ntau dua. Txawm li cas los xij:

Ntev-wavelength lasers ua rau thermal puas.

Cov lasers luv luv ua rau cov khib nyiab hnyav thiab ua rau cov txheej txheem puas tsuaj, ua kom polishing complexity.

Mechanical Polishing Workflow rau SiC

Cov txheej txheem dav dav suav nrog:

Orientation txiav

Coarse sib tsoo

Kev sib tsoo zoo

Tshuab polishing

Chemical Mechanical Polishing (CMP) raws li cov kauj ruam kawg

Qhov kev xaiv ntawm CMP txoj kev, txheej txheem txoj kev tsim, thiab optimization ntawm tsis yog ib qho tseem ceeb heev. Hauv kev tsim khoom semiconductor, CMP yog qhov kev txiav txim siab rau kev tsim SiC wafers nrog ultra-smooth, tsis muaj qhov tsis xws luag, thiab tsis muaj kev puas tsuaj, uas yog qhov tseem ceeb rau kev loj hlob zoo epitaxial.

(a) Tshem tawm SiC ingot ntawm lub crucible;

(b) Ua qhov pib shaping siv sab nraud sib tsoo;

(c) Txiav txim siab qhov kev taw qhia siv lead ua siv cov kev sib haum xeeb los yog qhov chaw;

(d) Txiav cov ingot rau hauv nyias wafers siv ntau txoj hlua sawing;

(e) Ua tiav daim iav zoo li nto smoothness los ntawm kev sib tsoo thiab polishing cov kauj ruam.

Tom qab ua tiav cov txheej txheem ntawm kev ua tiav, sab ntug ntawm SiC wafer feem ntau dhau los ua ntse, uas ua rau muaj kev pheej hmoo ntawm chipping thaum tuav lossis siv. Txhawm rau kom tsis txhob muaj qhov fragility, ntug kev sib tsoo yog yuav tsum tau.

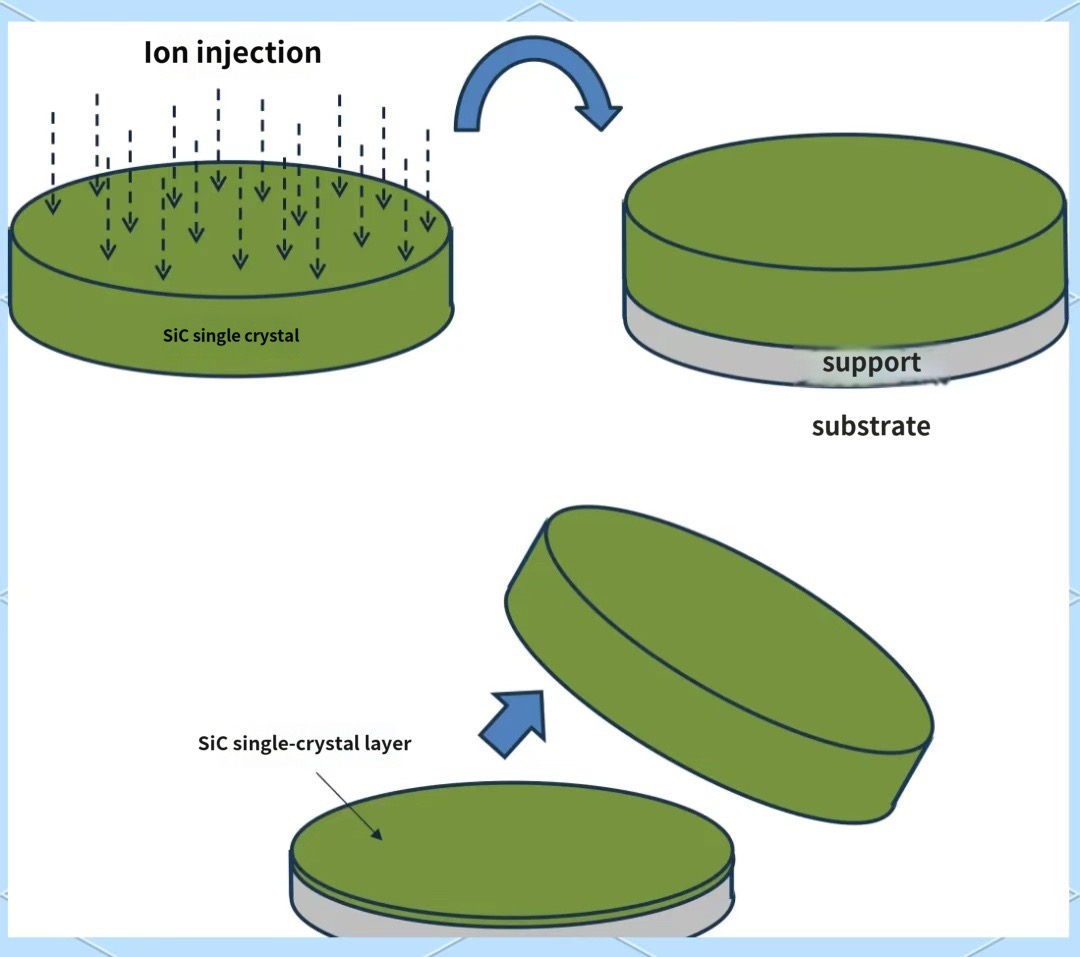

Ntxiv nrog rau cov txheej txheem slicing ib txwm, ib txoj hauv kev tshiab rau kev npaj SiC wafers koom nrog kev siv tshuab. Txoj hauv kev no ua rau wafer fabrication los ntawm kev sib koom ua ke nyias SiC ib leeg-crystal txheej rau cov txheej txheem sib txawv (txhawb substrate).

Daim duab 3 qhia txog kev khiav dej num:

Ua ntej, txheej txheej delamination yog tsim ntawm qhov tob ntawm qhov chaw ntawm SiC ib leeg siv lead ua los ntawm hydrogen ion implantation lossis cov txheej txheem zoo sib xws. Cov txheej txheem SiC ib leeg siv lead ua yog tom qab ntawd txuas rau lub tiaj tus txhawb nqa substrate thiab raug rau siab thiab kub. Qhov no tso cai rau kev hloov pauv tau zoo thiab sib cais ntawm SiC ib leeg-crystal txheej mus rau qhov kev txhawb nqa substrate.

Cov txheej txheem SiC sib cais tau txais kev kho saum npoo kom ua tiav qhov yuav tsum tau ua kom tiaj tus thiab tuaj yeem rov qab siv dua hauv cov txheej txheem txuas ntxiv. Muab piv rau cov tsoos slicing ntawm SiC muaju, cov txheej txheem no txo qhov kev thov rau cov khoom kim heev. Txawm hais tias muaj kev sib tw hauv kev lag luam, kev tshawb fawb thiab kev tsim kho tau nquag ua kom muaj peev xwm ua kom cov nqi qis dua.

Muab lub siab tawv thiab tshuaj lom neeg ruaj khov ntawm SiC - uas ua rau nws tiv taus cov tshuaj tiv thaiv ntawm chav tsev kub - cov tshuab polishing yuav tsum tau tshem tawm cov qhov sib tsoo zoo, txo qhov kev puas tsuaj, tshem tawm khawb, pitting, thiab txiv kab ntxwv tev tsis xws luag, qis nto roughness, txhim kho flatness, thiab txhim kho nto zoo.

Yuav kom ua tiav qhov zoo polished nto, nws yuav tsum tau:

Kho hom abrasive,

Txo particle loj,

Optimize txheej txheem parameter,

Xaiv cov ntaub ntawv polishing thiab cov ntaub qhwv nrog cov hardness txaus.

Daim duab 7 qhia tau hais tias ob-sided polishing nrog 1 μm abrasives tuaj yeem tswj kev tiaj tus thiab thickness variation li ntawm 10 μm, thiab txo qhov roughness ntawm 0.25 nm.

3.2 Chemical Mechanical Polishing (CMP)

Chemical Mechanical Polishing (CMP) ua ke nrog cov khoom siv ultrafine abrasion nrog cov tshuaj etching los ua ib tug du, planar nto ntawm cov khoom ua tiav. Lub hauv paus ntsiab lus yog:

Ib qho tshuaj tiv thaiv tshwm sim ntawm polishing slurry thiab wafer nto, tsim ib txheej mos.

Kev sib txhuam ntawm cov khoom abrasive thiab cov txheej mos tshem tawm cov khoom.

CMP qhov zoo:

Overcomes lub drawbacks ntawm purely mechanical los yog tshuaj polishing,

Ua tiav ob qho tib si thoob ntiaj teb thiab hauv zos planarization,

Ua cov nto nrog siab flatness thiab tsawg roughness,

Tawm tsis muaj qhov chaw los yog subsurface puas.

Hauv kev nthuav dav:

Lub wafer txav txheeb ze rau polishing ncoo nyob rau hauv siab.

Nanometer-scale abrasives (piv txwv li, SiO₂) hauv slurry koom nrog shearing, tsis muaj zog Si-C covalent bonds thiab txhim kho cov khoom tshem tawm.

Hom CMP Cov Txheej Txheem:

Dawb Abrasive Polishing: Abrasives (xws li SiO₂) raug tshem tawm hauv slurry. Kev tshem tawm cov khoom tshwm sim los ntawm peb lub cev abrasion (wafer-pad-abrasive). Abrasive loj (feem ntau 60-200 nm), pH, thiab qhov kub thiab txias yuav tsum tau tswj kom meej meej kom zoo sib xws.

Tsau Abrasive Polishing: Abrasives yog embedded nyob rau hauv lub polishing ncoo los tiv thaiv agglomeration - zoo tagnrho rau high-precision ua.

Tom qab Polishing Cleaning:

Polished wafers undergo:

Kev ntxuav tshuaj (nrog rau DI dej thiab slurry residue tshem tawm),

DI dej yaug, thiab

Kub nitrogen kom qhuav

kom txo cov kab mob ntawm qhov chaw.

Surface Quality & Performance

Deg roughness yuav raug txo mus rau Ra <0.3 nm, ua tau raws li semiconductor epitaxy yuav tsum tau.

Ntiaj teb no Planarization: Kev sib xyaw ntawm cov tshuaj softening thiab cov neeg kho tshuab tshem tawm txo cov khawb thiab tsis sib xws etching, outperforming ntshiab txhua yam los yog tshuaj txoj kev.

High Efficiency: Haum rau cov ntaub ntawv nyuaj thiab nkig zoo li SiC, nrog cov khoom tshem tawm ntau dua 200 nm / h.

Lwm Cov Txheej Txheem Tshaj Tawm Polishing

Ntxiv rau CMP, lwm txoj hauv kev tau thov, suav nrog:

Electrochemical polishing, Catalyst-pab polishing lossis etching, thiab

Tribochemical polishing.

Txawm li cas los xij, cov txheej txheem no tseem nyob rau theem tshawb fawb thiab tau tsim qeeb vim SiC cov khoom nyuaj.

Thaum kawg, SiC ua tiav yog ib qho txheej txheem ntawm kev txo qis warpage thiab roughness los txhim kho qhov zoo, qhov twg flatness thiab roughness tswj yog qhov tseem ceeb thoob plaws txhua theem.

Kev Siv Tshuab

Thaum lub sij hawm wafer sib tsoo theem, pob zeb diamond slurry nrog sib txawv particle loj yog siv los zom cov wafer mus rau qhov yuav tsum tau flatness thiab nto roughness. Qhov no yog ua raws li polishing, siv ob qho tib si txhua yam thiab tshuaj kho tshuab polishing (CMP) cov tswv yim los tsim kev puas tsuaj-dawb polished silicon carbide (SiC) wafers.

Tom qab polishing, SiC wafers tau txais kev tshuaj xyuas zoo siv cov cuab yeej xws li optical microscopes thiab X-ray diffractometers los xyuas kom meej tag nrho cov kev ntsuas tsis tau raws li cov qauv xav tau. Thaum kawg, polished wafers raug ntxuav siv cov tshuaj ntxuav tshwj xeeb thiab dej ultrapure kom tshem tawm cov kab mob ntawm qhov chaw. Tom qab ntawd lawv qhuav siv ultra-high purity nitrogen gas thiab kiv tshuab ziab khaub ncaws, ua tiav tag nrho cov txheej txheem tsim khoom.

Tom qab xyoo ntawm kev siv zog, kev vam meej tseem ceeb tau ua nyob rau hauv SiC ib leeg siv lead ua hauv Suav teb. Hauv tsev, 100 hli doped semi-insulating 4H-SiC ib leeg siv lead ua tau ua tiav, thiab n-hom 4H-SiC thiab 6H-SiC ib leeg muaju tam sim no tuaj yeem ua rau hauv cov khoom siv. Cov tuam txhab xws li TankeBlue thiab TYST twb tau tsim 150 mm SiC ib leeg siv lead ua.

Nyob rau hauv cov nqe lus ntawm SiC wafer ua technology, cov tsev hauv tsev tau tshawb fawb ua ntej cov txheej txheem thiab txoj hauv kev rau siv lead ua slicing, sib tsoo, thiab polishing. Lawv muaj peev xwm tsim tau cov qauv uas ua tau raws li qhov yuav tsum tau ua rau kev tsim khoom siv. Txawm li cas los xij, piv rau cov qauv thoob ntiaj teb, qhov ua tau zoo ntawm cov wafers hauv tsev tseem poob qis dua. Muaj ntau yam teeb meem:

International SiC theories thiab kev siv thev naus laus zis tau tiv thaiv nruj thiab tsis yooj yim nkag mus.

Tsis muaj kev tshawb fawb theoretical thiab kev txhawb nqa rau kev txhim kho thiab kev ua kom zoo.

Tus nqi ntawm kev xa khoom txawv teb chaws thiab cov khoom siv yog siab.

Kev tshawb fawb hauv tsev ntawm cov khoom tsim, kev ua tiav, thiab cov ntaub ntawv tseem qhia tau tias muaj qhov sib txawv tseem ceeb piv rau qib thoob ntiaj teb.

Tam sim no, feem ntau cov cuab yeej siv high-precision siv hauv Suav teb raug xa tawm. Cov cuab yeej kuaj thiab cov txheej txheem kuj tseem xav tau kev txhim kho ntxiv.

Nrog rau kev txhim kho txuas ntxiv ntawm tiam thib peb semiconductors, txoj kab uas hla ntawm SiC ib leeg siv lead ua substrates tau nce zuj zus, nrog rau kev xav tau ntau dua rau kev ua haujlwm zoo. Wafer ua tshuab tau dhau los ua ib qho ntawm cov txheej txheem nyuaj tshaj plaws tom qab SiC ib leeg siv lead ua loj hlob.

Txhawm rau daws cov teeb meem uas twb muaj lawm hauv kev ua tiav, nws yog qhov tseem ceeb kom kawm ntxiv txog cov txheej txheem cuam tshuam nrog kev txiav, sib tsoo, thiab polishing, thiab tshawb nrhiav cov txheej txheem tsim nyog thiab txoj hauv kev rau SiC wafer manufacturing. Nyob rau tib lub sijhawm, nws yog ib qho tsim nyog yuav tsum kawm los ntawm cov txheej txheem thoob ntiaj teb kev ua haujlwm siab heev thiab txais yuav cov txheej txheem ultra-precision machining thiab cov cuab yeej siv los tsim cov khoom zoo.

Raws li wafer loj zuj zus, qhov nyuaj ntawm crystal kev loj hlob thiab kev ua haujlwm kuj nce. Txawm li cas los xij, kev tsim khoom ntawm cov khoom siv downstream txhim kho tau zoo, thiab cov nqi tsev raug txo. Tam sim no, lub ntsiab SiC wafer cov khoom lag luam thoob ntiaj teb muab cov khoom lag luam xws li 4 ntiv tes mus rau 6 ntiv tes inch. Cov tuam txhab ua lag luam xws li Cree thiab II-VI tau pib npaj rau kev txhim kho 8-nti SiC wafer cov kab ntau lawm.

Post lub sij hawm: May-23-2025