Robotic Polishing Tshuab - High-Precision Automated Nto Finishing

Daim duab qhia ntxaws

Txheej txheem cej luam ntawm Robotic Polishing Tshuab

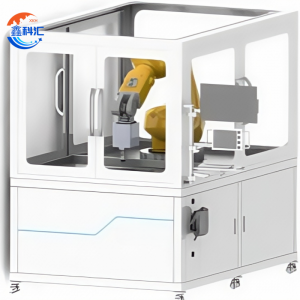

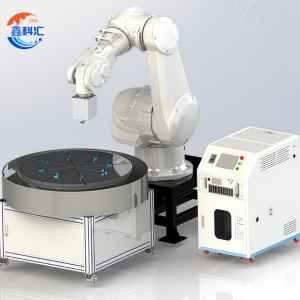

Lub Tshuab Robotic Polishing yog ib qho kev ua haujlwm siab heev, ua tiav qhov kev ua haujlwm ntawm qhov chaw tsim los ua kom tau raws li qhov xav tau siab tshaj plaws hauv kev tsim khoom. Nws ua ke rau 6-axis neeg hlau tswj, quab yuam-thov rov qab polishing thev naus laus zis, thiab kev teeb tsa dual-lub taub hau los tswj cov khoom siv ntau yam thiab cov geometries nyuaj nrog qhov tseeb tshwj xeeb thiab sib xws.

Txawm hais tias yog rau cov lo ntsiab muag kho qhov muag, aerospace qhov chaw, precision engineering Cheebtsam, los yog daim ntawv thov semiconductor, lub tshuab no muab kev ruaj khov, rov ua tau zoo, thiab cov khoom zoo tshaj plaws-txawm ntawm nanometer-theem kam rau ua.

Comprehensive Workpiece Compatibility ntawm Robotic Polishing Tshuab

Lub system txhawb kev ua haujlwm ntawm:

-

Cov chaw tiaj tusrau iav, ceramics, thiab hlau phaj

-

Cov duab cylindrical thiab conicalxws li rollers, shafts, thiab tubes

-

Spherical thiab aspherical Cheebtsamrau optical systems

-

Freeform thiab off-axis ntonrog complex curves thiab kev hloov

Nws versatility ua rau nws haum rauob qho tib si loj ntau lawm thiab high-precision customized manufacturing.

Core Nta & Cov txiaj ntsig ntawm Robotic Polishing Tshuab

1. Dual Polishing taub hau Technology

-

Nruab nrogkev sib hloovthiabkev hloov tus kheejpolishing taub hau rau yooj.

-

Cov cuab yeej hloov pauv ceev muaj peev xwm txhawb nqa ntau hom kev ua haujlwm yam tsis muaj sijhawm poob ntev.

-

Zoo tagnrho rau kev hloov ntawm coarse thiab nplua polishing theem.

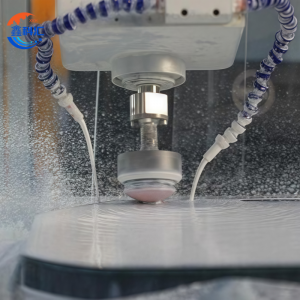

2. Precision Force-Control System

-

Real-time saib xyuas ntawmsiab, kub, thiab polishing kua ntws.

-

Daim ntawv thov quab yuam ua kom ntseeg tau tias muaj qhov sib txawv ntawm qhov chaw ua haujlwm.

-

Muaj peev xwm hloov mus rau qhov chaw irregularities txiav.

3. Six-Axis Robotic Control

-

Tag nrho txoj kev ywj pheej ntawm kev txav mus los tswj cov geometry nyuaj.

-

Txoj kev yooj yim, muaj tseeb, suav nrog cov algorithms siab heev.

-

Siab rov ua qhov tseeb ntawm ± 0.04 hli mus rau ± 0.1 hli nyob ntawm tus qauv.

4. Ntse Automation & Ntsuas

-

Auto-calibration cov cuab yeej rau kev teeb tsa thiab kev sib dhos.

-

Coordinate ntsuas system rau qhov tseeb qhov chaw.

-

xaiv tauonline thickness xyuasrau real-time kev tswj kom zoo.

5. Muaj-Qib Tsim Zoo

-

Dual servo-motor tsim ua rau kom polishing efficiency thiab stability.

-

Rigid mechanical structure minimizes vibration thiab ua kom lub sij hawm ntev.

Technical Specifications ntawm Robotic Polishing Tshuab

| Cov khoom siv qauv | Neeg hlau lub cev | Rov ua qhov tseeb qhov tseeb | Txheej Txheem Ntau Yam | Ib leeg tig Polishing taub hau | Multi-Rotation Polishing Lub taub hau | Cov cuab yeej me me | Main Log Hom Polishing | Spherical taub hau Polishing | Xaus Kev Hloov Ceev | Nws pib Calibration Tool | Coordinate Measurement Head | Online Thickness Saib Xyuas | Numerical Control Platform |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IRP 500 S | Staubli TX 2-90L | ± 0.04mm / ntau yam | Φ50 ~ Φ500mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| IRP 600 S | Staubli TX 2-140 | ± 0.05mm / ntau yam | Φ50 ~ Φ600mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| IRP 800 S | Staubli TX 2-160 | ± 0.05mm / ntau yam | Φ80 ~ Φ800mm | √ | √ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP1000S | Staubli TX 200/L | ± 0.06mm / ntau yam | Φ100 ~ Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP1000A | ABB IRB6700-200/2.6 | ± 0.1mm / ntau yam | Φ100 ~ Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP 2000A | ABB IRB6700-150/3.2 | ± 0.1mm / ntau yam | Φ200 ~ Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

| IRP 2000 AD | ABB IRB6700-150/3.2 | ± 0.1mm / ntau yam | Φ200 ~ Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

FAQ - Neeg Hlau Polishing Tshuab

1. Dab tsi ntawm workpieces tuaj yeem ua tus neeg hlau polishing tshuab?

Peb cov neeg hlau polishing tshuab txhawb ntau yam duab thiab qhov chaw, xws li tiaj tus, nkhaus, kheej kheej, freeform, thiab complex contours. Nws yog tsim rau optical Cheebtsam, precision pwm, hlau nto, thiab lwm yam high-precision polishing daim ntaub ntawv.

2. Dab tsi yog qhov sib txawv ntawm Ib Leeg Kev Sib Hloov thiab Multi-Rotation polishing hau?

-

Ib leeg tig Polishing taub hau: Cov cuab yeej tig ib ncig ntawm ib qho axis, zoo tagnrho rau cov txheej txheem nto tiav thiab tshem tawm cov khoom siv ceev ceev.

-

Multi-Rotation Polishing Lub taub hau: Cov cuab yeej sib txuas ua ke nrog kev sib hloov ntawm tus kheej (orbiting), ua kom muaj kev sib txhuam ntau dua ntawm cov npoo nkhaus thiab tsis sib xws.

3. Dab tsi yog qhov kev ua haujlwm siab tshaj plaws?

Nyob ntawm tus qauv:

-

Compact qauv (piv txwv li, IRP500S) kovΦ50-Φ500mm.

-

Cov qauv loj (piv txwv li, IRP2000AD) tuav txog liΦ2000 hli.

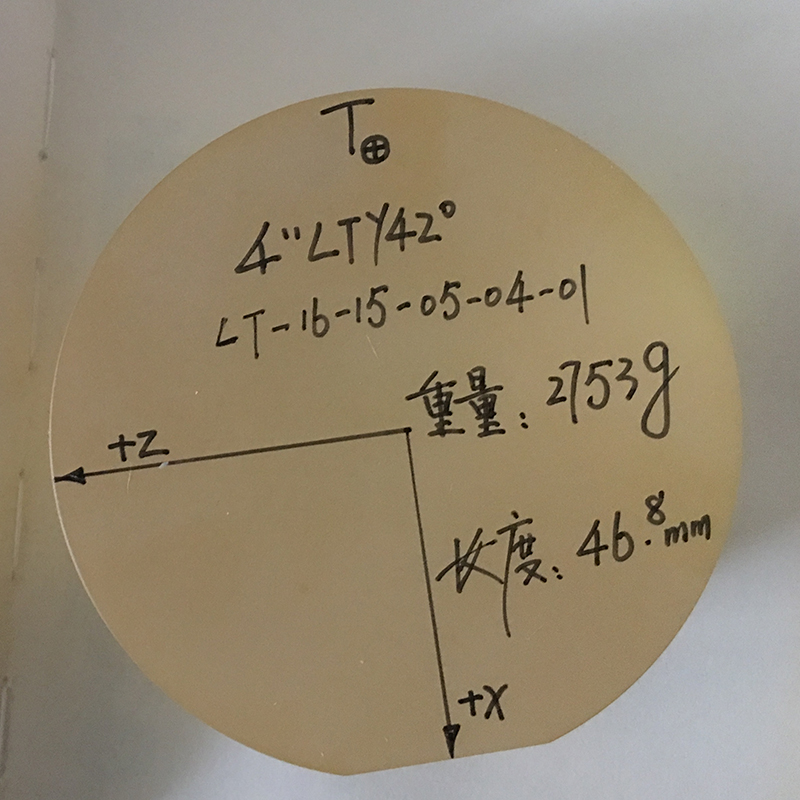

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.