SiC ceramic phaj / tais rau 4inch 6inch wafer yas dhos rau ICP

SiC ceramic phaj Abstract

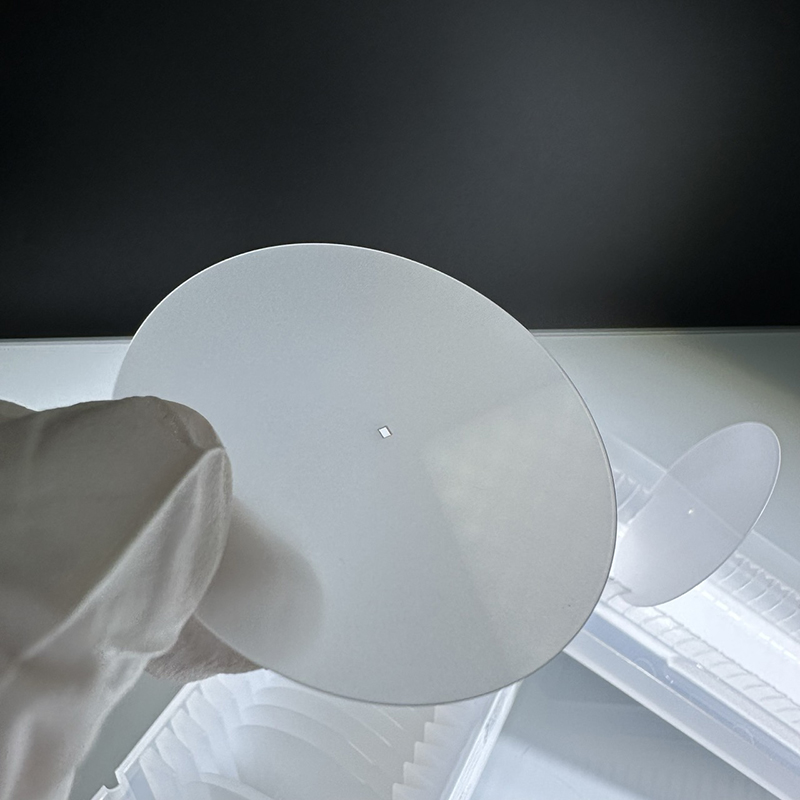

SiC ceramic phaj yog cov khoom siv ua haujlwm siab tsim los ntawm cov khoom siv siab huv silicon Carbide, tsim los siv rau hauv huab cua kub, tshuaj lom neeg, thiab kev siv tshuab. Renowned rau nws tshwj xeeb hardness, thermal conductivity, thiab corrosion kuj, SiC phaj yog dav siv raws li ib tug wafer carrier, susceptor, los yog structural tivthaiv nyob rau hauv semiconductor, LED, photovoltaic, thiab aerospace industries.

Nrog zoo thermal stability mus txog 1600 ° C thiab zoo heev tsis kam rau reactive gases thiab plasma ib puag ncig, lub SiC phaj ua kom zoo ib yam kev ua tau zoo thaum lub sij hawm kub-kub etching, deposition, thiab diffusion txheej txheem. Nws ntom, tsis muaj kev siv microstering electructure, ua rau nws zoo tagnrho rau cov ntaub ntawv huv lim hauv lub tshuab nqus tsev lossis dej huv.

SiC ceramic phaj daim ntawv thov

1. Kev tsim khoom semiconductor

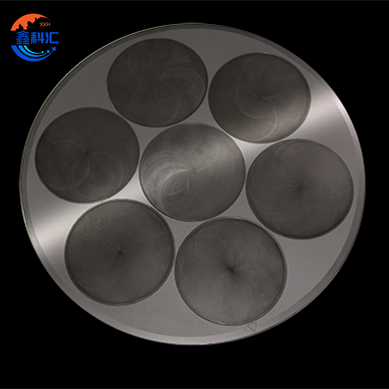

SiC ceramic phaj feem ntau yog siv los ua wafer nqa, susceptors, thiab pedestal phaj hauv semiconductor fabrication khoom xws li CVD (Chemical Vapor Deposition), PVD (Lub cev Vapor Deposition), thiab etching systems. Lawv cov thermal conductivity zoo heev thiab tsis tshua muaj thermal expansion tso cai rau lawv kom muaj qhov sib txawv ntawm qhov kub thiab txias, uas yog qhov tseem ceeb rau kev ua haujlwm siab wafer. SiC qhov kev tiv thaiv rau corrosive gases thiab plasmas ua kom ruaj khov nyob rau hauv ib puag ncig hnyav, pab txo cov kab mob thiab cov khoom siv tu.

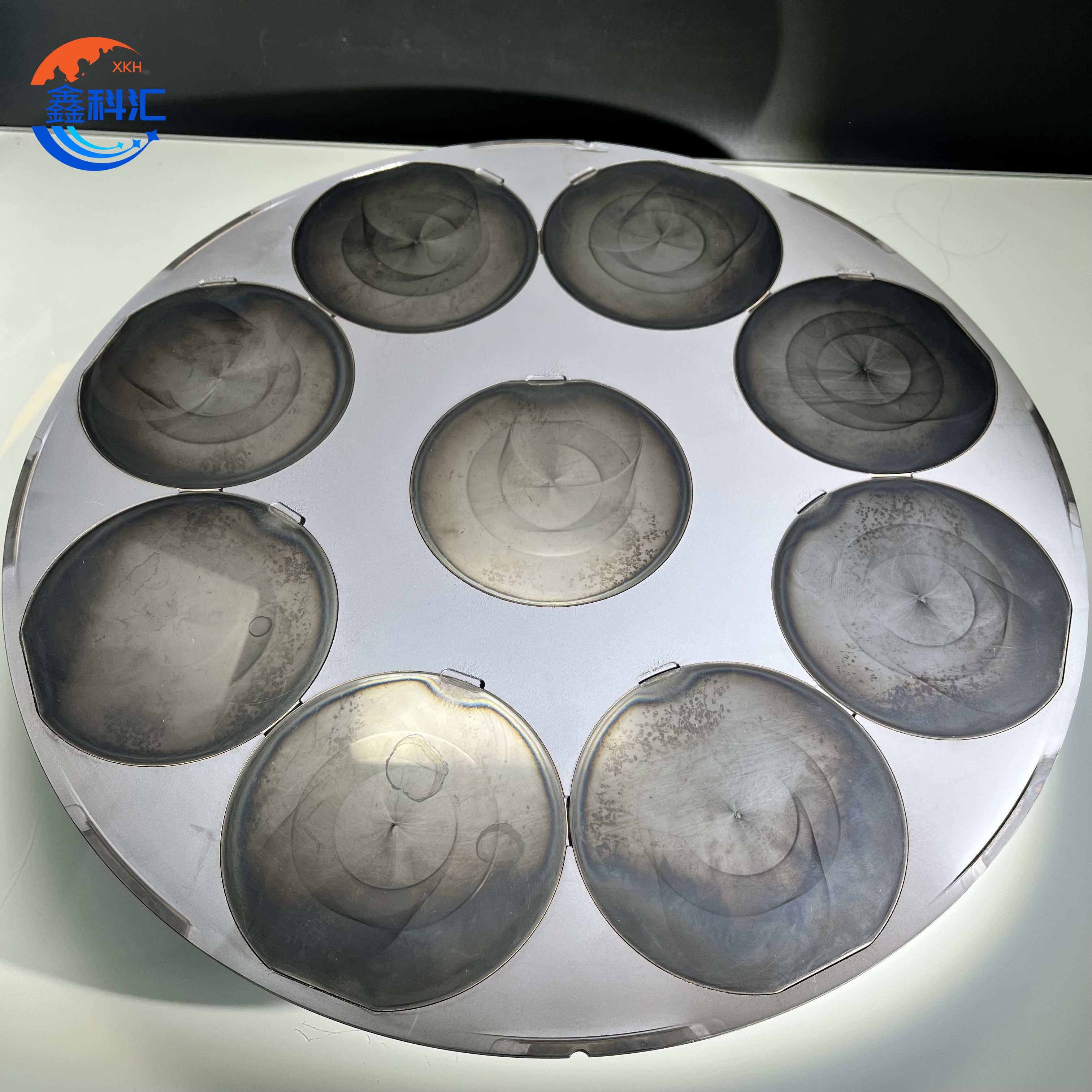

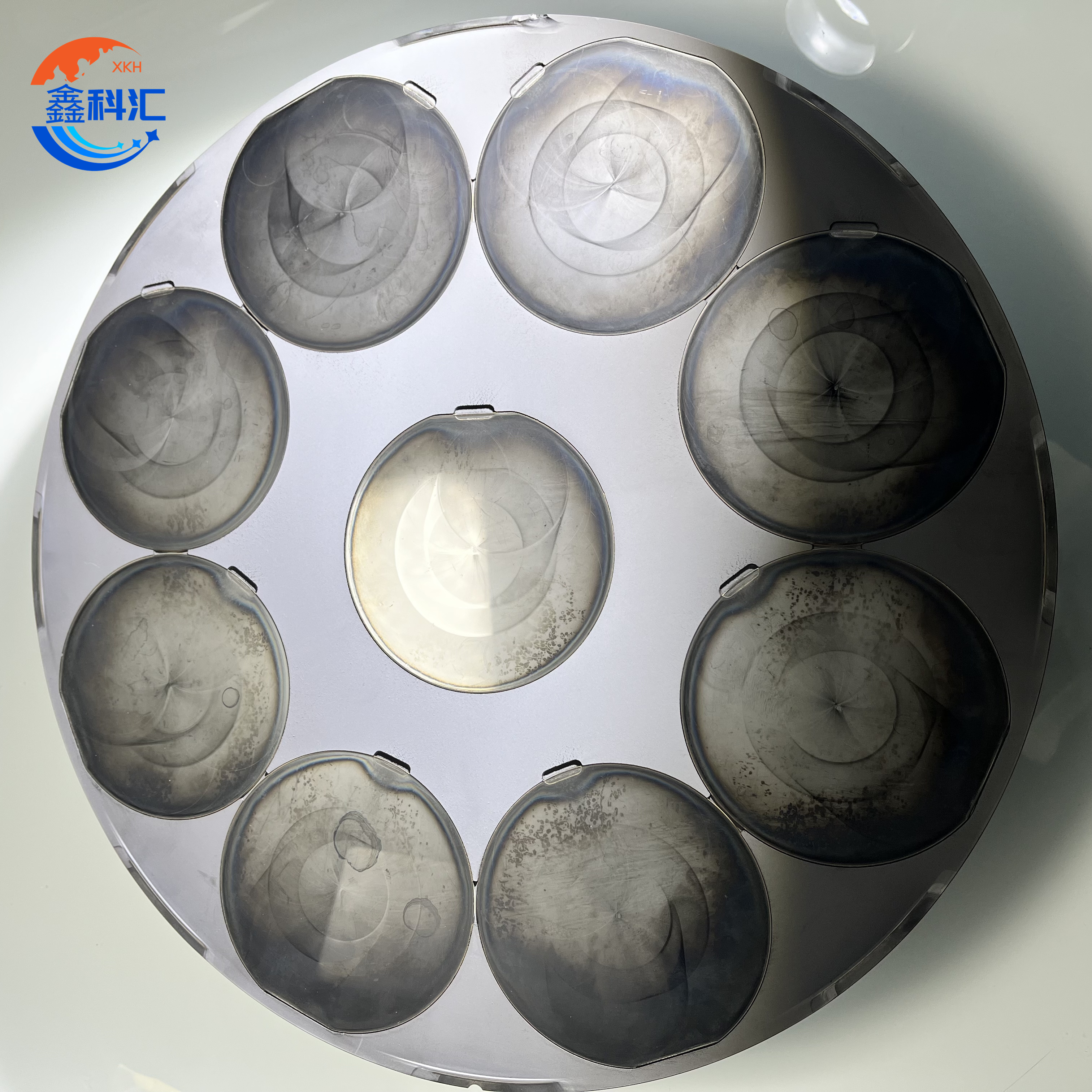

2. LED Kev Lag Luam - ICP Etching

Hauv kev lag luam LED, SiC daim hlau yog cov khoom tseem ceeb hauv ICP (Inductively Coupled Plasma) etching systems. Ua raws li cov tuav wafer, lawv muab lub platform ruaj khov thiab muaj zog thermally txhawb nqa sapphire lossis GaN wafers thaum lub sijhawm ua cov ntshav. Lawv cov ntshav plasma zoo heev, nto flatness, thiab seem stability pab kom siab etching raug thiab uniformity, ua rau muaj zog yield thiab ntaus ntawv ua tau zoo nyob rau hauv LED chips.

3. Photovoltaics (PV) thiab Hnub Ci Zog

SiC ceramic phaj kuj tseem siv rau hauv kev tsim cov hnub ci, tshwj xeeb tshaj yog thaum kub kub sintering thiab annealing kauj ruam. Lawv inertness ntawm siab kub thiab muaj peev xwm tiv thaiv warping kom zoo ib yam ntawm silicon wafers. Tsis tas li ntawd, lawv qhov kev pheej hmoo tsis muaj paug tsawg yog qhov tseem ceeb rau kev tswj xyuas kev ua haujlwm ntawm cov cell photovoltaic.

SiC ceramic phaj Properties

1. Exceptional Mechanical Strength thiab Hardness

SiC ceramic daim hlau nthuav tawm cov neeg kho tshuab siab heev, nrog lub zog flexural ntau tshaj 400 MPa thiab Vickers hardness ncav> 2000 HV. Qhov no ua rau lawv tiv taus cov neeg kho tshuab hnav, ua kom puas, thiab deformation, ua kom lub neej ua haujlwm ntev txawm tias nyob rau hauv siab load lossis rov ua dua thermal cycling.

2. High thermal conductivity

SiC muaj cov thermal conductivity zoo heev (feem ntau 120-200 W / m·K), tso cai rau nws sib npaug faib cov cua sov thoob plaws nws qhov chaw. Cov cuab yeej no tseem ceeb heev hauv cov txheej txheem xws li wafer etching, deposition, los yog sintering, qhov twg kub uniformity ncaj qha cuam tshuam cov khoom yield thiab zoo.

3. Superior Thermal stability

Nrog lub siab melting point (2700 ° C) thiab qis coefficient ntawm thermal expansion (4.0 × 10⁻⁶ / K), SiC ceramic daim hlau tuav qhov tseeb qhov tseeb thiab cov qauv kev ntseeg nyob rau hauv cov cua kub ceev thiab cua txias. Qhov no ua rau lawv zoo tagnrho rau cov ntawv thov hauv qhov cub kub kub, lub tshuab nqus tsev, thiab cov plasma ib puag ncig.

| Technical Properties | ||||

| Index | Chav tsev | Tus nqi | ||

| Khoom npe | Cov tshuaj tiv thaiv Sintered Silicon Carbide | Siab tsis muaj Sintered Silicon Carbide | Recrystallized Silicon Carbide | |

| Kev sib xyaw | RBSiC | SIB | R-SiC | |

| Kev ceev ceev | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 Nws |

| Flexural zog | MPa (kpsi) | 338 (49) hnub | 380 (55) hnub | 80-90 (20 ° C) 90-100 (1400 ° C) |

| Compressive zog | MPa (kpsi) | 1120 (158) hnub | 3970 (560) hnub | > 600 |

| Hardness | Knoop | 2700 | 2800 | / |

| Txhaum Tenacity | MPa m1/2 | 4.5 | 4 | / |

| Thermal conductivity | W/mk | 95 | 120 | 23 |

| Coefficient ntawm Thermal Expansion | 10-6.1/°C | 5 | 4 | 4.7 |

| Tshwj xeeb kub | Joule/g 0k | 0.8 ua | 0.67 ib | / |

| Max kub hauv huab cua | ℃ | 1200 | 1500 | 1600 |

| Elastic Modulus | Gpa | 360 | 410 | 240 |

SiC ceramic phaj Q&A

Q: Dab tsi yog cov khoom ntawm silicon carbide phaj?

A: Silicon carbide (SiC) daim hlau paub txog lawv lub zog siab, hardness, thiab thermal stability. Lawv muab cov thermal conductivity zoo heev thiab tsis tshua muaj thermal expansion, kom ntseeg tau tias kev ua tau zoo nyob rau hauv huab cua kub. SiC tseem yog tshuaj lom neeg tsis muaj zog, tiv taus cov kua qaub, alkalis, thiab ntshav plasma ib puag ncig, ua rau nws zoo tagnrho rau kev ua haujlwm semiconductor thiab LED. Nws ntom, du nto minimizes particle tiam, tswj cleanroom compatibility. SiC daim hlau yog dav siv los ua wafer nqa, susceptors, thiab txhawb cov khoom nyob rau hauv high-temperature thiab corrosive ib puag ncig nyob rau hauv lub semiconductor, photovoltaic, thiab aerospace industries.