4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer rau MOS lossis SBD

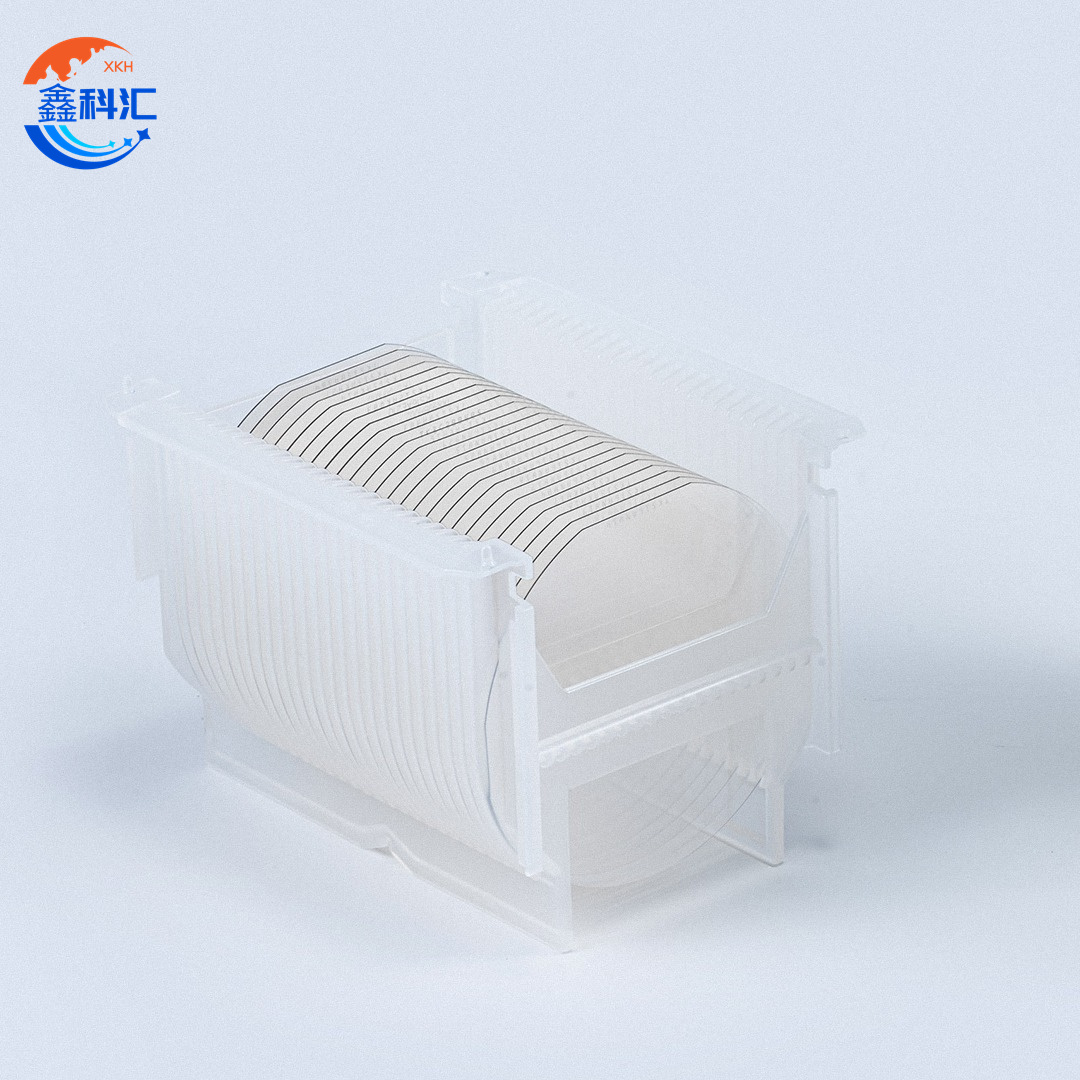

SiC Substrate SiC Epi-wafer Luv luv

Peb muab tag nrho cov ntaub ntawv zoo ntawm SiC substrates thiab sic wafers nyob rau hauv ntau yam polytypes thiab doping profiles-xws li 4H-N (n-hom conductive), 4H-P (p-type conductive), 4H-HPSI (high-purity semi-insulating), thiab 6H-P (p-type conductive), 8 ″, txoj kab uas hla. 12″. Tshaj li cov substrates liab qab, peb cov kev pabcuam kev loj hlob epitaxial (epi) wafers nrog nruj tswj thickness (1-20 µm), doping concentrations, thiab defect ntom ntom.

Txhua lub sic wafer thiab epi wafer tau soj ntsuam nruj hauv kab (micropipe ntom <0.1 cm⁻², nto roughness Ra <0.2 nm) thiab tag nrho hluav taws xob characterization (CV, resistivity mapping) kom paub meej tshwj xeeb siv lead ua uniformity thiab kev ua tau zoo. Txawm hais tias siv rau cov khoom siv hluav taws xob hluav taws xob, cov khoom siv hluav taws xob ntau zaus RF, lossis cov khoom siv hluav taws xob optoelectronic (LEDs, photodetectors), peb cov khoom siv SiC substrate thiab epi wafer xa cov kev ntseeg siab, thermal stability, thiab kev puas tsuaj lub zog xav tau los ntawm niaj hnub no cov kev xav tau tshaj plaws.

SiC Substrate 4H-N yam khoom thiab daim ntawv thov

-

4H-N SiC substrate Polytype (Hexagonal) Structure

Dav bandgap ntawm ~ 3.26 eV ua kom ruaj khov hluav taws xob ua haujlwm thiab thermal robustness nyob rau hauv high-temperature thiab high-electric-field tej yam kev mob.

-

SiC substrateN-Type Doping

Precisely tswj nitrogen doping yields carrier concentrations ntawm 1 × 10¹⁶ mus rau 1 × 10¹⁹ cm⁻³ thiab chav-kub electron mobilities mus txog ~ 900 cm² / V·s, minimizing conduction losses.

-

SiC substrateWide Resistivity & Uniformity

Muaj kev tiv thaiv ntau ntawm 0.01-10 Ω·cm thiab wafer thicknesses ntawm 350-650 µm nrog ± 5% kam rau ua ob qho tib si doping thiab thickness-zoo tagnrho rau high-power device fabrication.

-

SiC substrateUltra-Low Defect Density

Micropipe ntom <0.1 cm⁻² thiab basal-plane dislocation ceev <500 cm⁻², xa> 99% ntaus ntawv tawm los thiab superior siv lead ua kev ncaj ncees.

- SiC substrateExceptional Thermal conductivity

Thermal conductivity mus txog ~ 370 W / m·K ua kom yooj yim tshem tawm cov cua sov, txhawb cov cuab yeej kev ntseeg tau thiab lub zog ceev.

-

SiC substrateDaim phiaj siv

SiC MOSFETs, Schottky diodes, fais fab modules thiab RF li rau hluav taws xob-tsheb tsav tsheb, hnub ci inverters, industrial drives, traction systems, thiab lwm yam xav tau lub hwj chim-electronics kev lag luam.

6inch 4H-N hom SiC wafer tus specification | ||

| Khoom | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

| Qib | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

| Txoj kab uas hla | 149.5 hli - 150.0 hli | 149.5 hli - 150.0 hli |

| Poly-hom | 4H | 4H |

| Thickness | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Wafer Orientation | Tawm axis: 4.0 ° mus rau <1120> ± 0.5 ° | Tawm axis: 4.0 ° mus rau <1120> ± 0.5 ° |

| Micropipe ntom ntom | ≤ 0.2 cm² | ≤ 15 cm² |

| Kev tiv thaiv | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Thawj Txoj Kev Ncaj Ncees | [10-10] ± 50° | [10-10] ± 50° |

| Qhov Loj Loj Loj | 475 hli ± 2.0 hli | 475 hli ± 2.0 hli |

| Ntug Exclusion | 3 hli | 3 hli |

| LTV/TIV/Bow/Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Roughness | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Rau | ≤ 0.2nm | ≤ 0.5nm |

| Ntug Cracks Los ntawm High Intensity Light | Kev sib sau ntev ≤ 20 hli ib qhov ntev ≤ 2 hli | Kev sib sau ntev ≤ 20 hli ib qhov ntev ≤ 2 hli |

| Hex Phaj Los Ntawm Lub Teeb Siab Siab | Qhov ntau thiab tsawg ≤ 0.05% | Cov cheeb tsam ≤ 0.1% |

| Polytype Areas Los Ntawm Lub Teeb Siab Siab | Qhov ntau thiab tsawg ≤ 0.05% | Cov cheeb tsam sib sau ≤ 3% |

| Visual Carbon suav nrog | Qhov ntau thiab tsawg ≤ 0.05% | Qhov ntau thiab tsawg ≤ 5% |

| Silicon Surface Scratches Los ntawm High Intensity Light | Qhov ntev ntev ≤ 1 wafer txoj kab uas hla | |

| Ntug Chips Los ntawm High Intensity Light | Tsis muaj kev tso cai ≥ 0.2 mm dav thiab qhov tob | 7 tso cai, ≤ 1mm txhua |

| Threading Screw Dislocation | <500 cm³ | <500 cm³ |

| Silicon Surface Contamination Los ntawm High Intensity Light | ||

| Ntim | Multi-wafer Cassette lossis Ib Lub Thawv Wafer | Multi-wafer Cassette lossis Ib Lub Thawv Wafer |

8inch 4H-N hom SiC wafer tus specification | ||

| Khoom | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

| Qib | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

| Txoj kab uas hla | 199.5mm - 200.0 hli | 199.5mm - 200.0 hli |

| Poly-hom | 4H | 4H |

| Thickness | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | 4.0 ° mus rau <110> ± 0.5 ° | 4.0 ° mus rau <110> ± 0.5 ° |

| Micropipe ntom ntom | ≤ 0.2 cm² | ≤ 5 cm² |

| Kev tiv thaiv | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Noble Orientation | ||

| Ntug Exclusion | 3 hli | 3 hli |

| LTV/TIV/Bow/Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Roughness | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Rau | ≤ 0.2nm | ≤ 0.5nm |

| Ntug Cracks Los ntawm High Intensity Light | Kev sib sau ntev ≤ 20 hli ib qhov ntev ≤ 2 hli | Kev sib sau ntev ≤ 20 hli ib qhov ntev ≤ 2 hli |

| Hex Phaj Los Ntawm Lub Teeb Siab Siab | Qhov ntau thiab tsawg ≤ 0.05% | Cov cheeb tsam ≤ 0.1% |

| Polytype Areas Los Ntawm Lub Teeb Siab Siab | Qhov ntau thiab tsawg ≤ 0.05% | Cov cheeb tsam sib sau ≤ 3% |

| Visual Carbon suav nrog | Qhov ntau thiab tsawg ≤ 0.05% | Qhov ntau thiab tsawg ≤ 5% |

| Silicon Surface Scratches Los ntawm High Intensity Light | Qhov ntev ntev ≤ 1 wafer txoj kab uas hla | |

| Ntug Chips Los ntawm High Intensity Light | Tsis muaj kev tso cai ≥ 0.2 mm dav thiab qhov tob | 7 tso cai, ≤ 1mm txhua |

| Threading Screw Dislocation | <500 cm³ | <500 cm³ |

| Silicon Surface Contamination Los ntawm High Intensity Light | ||

| Ntim | Multi-wafer Cassette lossis Ib Lub Thawv Wafer | Multi-wafer Cassette lossis Ib Lub Thawv Wafer |

4H-SiC yog cov khoom siv ua haujlwm siab siv rau cov khoom siv hluav taws xob hluav taws xob, RF cov khoom siv, thiab cov ntawv thov kub. Lub "4H" yog hais txog cov qauv siv lead ua, uas yog hexagonal, thiab "N" qhia txog hom doping siv los ua kom cov khoom ua tau zoo.

Cov4 H-SiChom yog feem ntau siv rau:

Lub zog Electronics:Siv rau hauv cov khoom siv xws li diodes, MOSFETs, thiab IGBTs rau cov tsheb fais fab fais fab, cov tshuab ua haujlwm, thiab cov tshuab hluav taws xob tauj dua tshiab.

5G Technology:Nrog 5G qhov kev thov rau cov khoom siv hluav taws xob ntau thiab ua haujlwm siab, SiC lub peev xwm los tswj cov hluav taws xob siab thiab ua haujlwm ntawm qhov kub siab ua rau nws zoo tagnrho rau lub hauv paus chaw nres tsheb fais fab amplifiers thiab RF li.

Solar Energy Systems:SiC cov khoom siv hluav taws xob zoo heev yog qhov zoo tagnrho rau photovoltaic (hnub ci zog) inverters thiab converters.

Electric Vehicles (EVs):SiC yog dav siv nyob rau hauv EV powertrains rau ntau npaum li cas zog hloov dua siab tshiab, txo tshav kub tiam, thiab ntau zog density.

SiC Substrate 4H Semi-Insulating yam khoom thiab daim ntawv thov

Khoom:

-

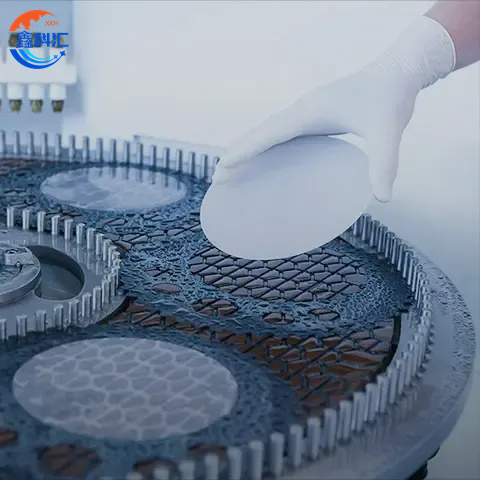

Micropipe-free density control techniques: Xyuas kom tsis muaj micropipes, txhim kho cov substrate zoo.

-

Monocrystalline tswj cov txheej txheem: Guarantees ib qho qauv siv lead ua rau cov khoom siv kho kom zoo.

-

Cov txheej txheem tswj kev suav nrog: Minimizes lub xub ntiag ntawm impurities los yog inclusions, kom ntseeg tau ib tug ntshiab substrate.

-

Cov txheej txheem tswj kev tiv thaiv: Tso cai rau kev tswj xyuas cov hluav taws xob tiv taus, uas yog qhov tseem ceeb rau kev ua haujlwm ntawm cov cuab yeej.

-

Cov txheej txheem tswj thiab tswj cov impurity: Tswj thiab txwv cov kev taw qhia ntawm impurities kom muaj kev ncaj ncees ntawm substrate.

-

Substrate kauj ruam dav tswj cov txheej txheem: Muab kev tswj xyuas qhov tseeb ntawm cov kauj ruam dav, kom ntseeg tau tias muaj kev sib xws ntawm cov substrate

6Inch 4H-semi SiC substrate specification | ||

| Khoom | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

| Txoj kab uas hla (mm) | 145mm-150 hli | 145mm-150 hli |

| Poly-hom | 4H | 4H |

| Thickness (hli) | 500 ± 15 | 500 ± 25 |

| Wafer Orientation | axis: ± 0.0001 ° | axis: ± 0.05 ° |

| Micropipe ntom ntom | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Kev tiv thaiv (Ω cm) | ≥10E3 | ≥10E3 |

| Thawj Txoj Kev Ncaj Ncees | (0-10) ° ± 5.0 ° | (10-10) ° ± 5.0 ° |

| Qhov Loj Loj Loj | Ntsig | Ntsig |

| Ntug Exclusion (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Tais / Warp | ≤ 3 µm | ≤ 3 µm |

| Roughness | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Ntug Chips Los ntawm High Intensity Light | ≤ 20 µm | ≤ 60 µm |

| Thaum tshav kub kub daim hlau los ntawm High Intensity Light | Kev sib tw ≤ 0.05% | Kev sib tw ≤ 3% |

| Polytype Areas Los Ntawm Lub Teeb Siab Siab | Kev pom cov pa roj carbon monoxide ≤ 0.05% | Kev sib tw ≤ 3% |

| Silicon Surface Scratches Los ntawm High Intensity Light | ≤ 0.05% | Kev sib tw ≤ 4% |

| Ntug Chips Los Ntawm Lub Teeb Siab Siab (loj) | Tsis Tso Cai> 02 mm Dav thiab qhov tob | Tsis Tso Cai> 02 mm Dav thiab qhov tob |

| Txoj Kev Pab Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Silicon Surface Contamination Los ntawm High Intensity Light | 1 x 10^5 | 1 x 10^5 |

| Ntim | Multi-wafer Cassette lossis Ib Lub Thawv Wafer | Multi-wafer Cassette lossis Ib Lub Thawv Wafer |

4-Inch 4H-Semi Insulating SiC Substrate Specification

| Parameter | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

|---|---|---|

| Lub cev muaj zog | ||

| Txoj kab uas hla | 99.5mm-100.0 hli | 99.5mm-100.0 hli |

| Poly-hom | 4H | 4H |

| Thickness | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Orientation | Ntawm axis: <600h> 0.5° | Ntawm axis: <000h> 0.5° |

| Cov khoom hluav taws xob | ||

| Micropipe Density (MPD) | ≤1cm⁻² | ≤ 15 cm⁻² |

| Kev tiv thaiv | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Geometric Tolerances | ||

| Thawj Txoj Kev Ncaj Ncees | (0x10) ± 5.0° | (0x10) ± 5.0° |

| Qhov Loj Loj Loj | 52.5 hli ± 2.0 hli | 52.5 hli ± 2.0 hli |

| Secondary Flat Length | 18.0 hli ± 2.0 hli | 18.0 hli ± 2.0 hli |

| Secondary Flat Orientation | 90 ° CW ntawm Prime tiaj tus ± 5.0 ° (Si ntsej muag) | 90 ° CW ntawm Prime tiaj tus ± 5.0 ° (Si ntsej muag) |

| Ntug Exclusion | 3 hli | 3 hli |

| LTV / TTV / Hneev / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10μm / ≤15μm / ≤25μm / ≤40μm |

| Nto Zoo | ||

| Nto Roughness (Polish Ra) | ≤ 1 nm | ≤ 1 nm |

| Nto Roughness (CMP Ra) | ≤ 0.2nm | ≤ 0.2nm |

| Ntug Cracks (High-Intensity Light) | Tsis tso cai | Qhov ntev ≥10 hli, ib qho tawg ≤2 hli |

| Hexagonal Phaj Defects | ≤0.05% cheeb tsam sib sau | ≤0.1% cheeb tsam sib sau |

| Polytype Inclusion Areas | Tsis tso cai | ≤1% cheeb tsam sib sau |

| Visual Carbon suav nrog | ≤0.05% cheeb tsam sib sau | ≤1% cheeb tsam sib sau |

| Silicon Surface Scratches | Tsis tso cai | ≤1 wafer txoj kab uas hla cumulative length |

| Ntug Chips | Tsis pub muaj (≥0.2 hli dav / qhov tob) | ≤5 nti (txhua ≤1 hli) |

| Silicon Surface Contamination | Tsis tau teev tseg | Tsis tau teev tseg |

| Ntim | ||

| Ntim | Multi-wafer cassette los yog ib lub thawv wafer | Multi-wafer cassette los yog |

Daim ntawv thov:

CovSiC 4H Semi-Insulating substratesfeem ntau yog siv nyob rau hauv high-power thiab high-frequency electronic devices, tshwj xeeb tshaj yog nyob rau hauv lubRF teb. Cov substrates no tseem ceeb heev rau ntau yam kev siv xws limicrowave kev sib txuas lus systems, Phase array radar, thiabwireless hluav taws xob ntes. Lawv cov thermal conductivity thiab cov yam ntxwv zoo ntawm hluav taws xob ua rau lawv zoo tagnrho rau kev thov hauv cov hluav taws xob hluav taws xob thiab kev sib txuas lus.

SiC epi wafer 4H-N yam khoom thiab daim ntawv thov

SiC 4H-N Hom Epi Wafer Properties thiab Daim Ntawv Thov

Cov khoom ntawm SiC 4H-N Hom Epi Wafer:

Khoom siv:

SiC (Silicon Carbide): Paub txog nws qhov zoo tshaj plaws hardness, siab thermal conductivity, thiab cov khoom hluav taws xob zoo heev, SiC yog qhov zoo tagnrho rau cov khoom siv hluav taws xob ua haujlwm siab.

4H-SiC Polytype: 4H-SiC polytype paub txog nws cov kev ua haujlwm siab thiab ruaj khov hauv kev siv hluav taws xob.

N-type Doping: N-hom doping (doped nrog nitrogen) muab cov khoom siv hluav taws xob zoo heev, ua SiC haum rau kev siv hluav taws xob ntau thiab muaj zog.

High Thermal conductivity:

SiC wafers muaj superior thermal conductivity, feem ntau xws li los ntawm120-200 W/m·K, cia lawv tswj cov cua sov hauv cov khoom siv hluav taws xob zoo li transistors thiab diodes.

Wide Bandgap:

Nrog ib tug bandgap ntawm3, 26 eV, 4H-SiC tuaj yeem ua haujlwm ntawm qhov hluav taws xob ntau dua, zaus, thiab qhov kub thiab txias piv rau cov khoom siv silicon-based, ua rau nws zoo tagnrho rau kev ua haujlwm siab, kev ua haujlwm siab.

Hluav taws xob cov khoom:

SiC lub siab electron txav thiab conductivity ua rau nws zoo tagnrho rauhluav taws xob hluav taws xob, muab kev hloov ceev ceev thiab siab tam sim no thiab voltage tuav lub peev xwm, ua rau muaj kev tswj xyuas hluav taws xob ntau dua.

Mechanical thiab Chemical Resistance:

SiC yog ib qho ntawm cov ntaub ntawv nyuaj tshaj plaws, thib ob tsuas yog pob zeb diamond, thiab muaj zog tiv taus oxidation thiab corrosion, ua rau nws ruaj khov nyob rau hauv ib puag ncig hnyav.

Daim ntawv thov ntawm SiC 4H-N Hom Epi Wafer:

Lub zog Electronics:

SiC 4H-N hom epi wafers yog dav siv nyob rau hauvzog MOSFETs, IGBTs, thiabdiodesrauhloov zoghauv systems xws lihnub ci inverter, hluav taws xob tsheb, thiabzog cia systems, muab kev txhim kho kev ua tau zoo thiab lub zog efficiency.

Electric Vehicles (EVs):

In electric tsheb powertrains, lub cev muaj zog controllers, thiabchaw them nqi, SiC wafers pab kom ua tiav cov roj teeb zoo dua, kev them nyiaj sai dua, thiab txhim kho tag nrho lub zog ua haujlwm vim lawv muaj peev xwm tswj tau lub zog siab thiab kub.

Renewable Energy Systems:

Hnub ci Inverters: SiC wafers yog siv rau hauvhnub ci zog systemsrau hloov DC lub zog los ntawm lub hnub ci vaj huam sib luag rau AC, ua kom tag nrho cov kev ua haujlwm tau zoo thiab ua haujlwm tau zoo.

Cua Turbines: SiC thev naus laus zis tau ua haujlwm hauvcua turbine tswj systems, optimizing zog tsim thiab hloov dua siab tshiab efficiency.

Aerospace thiab Defense:

SiC wafers yog qhov zoo tagnrho rau siv hauvaerospace hluav taws xobthiabkev siv tub rog, suav nrogradar systemsthiabsatellite electronics, qhov twg siab hluav taws xob tsis kam thiab thermal stability yog qhov tseem ceeb.

High-Temperature thiab High-Frequency Applications:

SiC wafers ua tau zoohigh-temperature electronics, siv hauvaircraft cav, lub dav hlau, thiabindustrial cua sov systems, raws li lawv tuav kev ua tau zoo nyob rau hauv huab cua kub tej yam kev mob. Tsis tas li ntawd, lawv qhov dav bandgap tso cai rau siv rau hauvkev siv high-frequencynyiamCov khoom siv RFthiabmicrowave kev sib txuas lus.

| 6-nti N-hom epit axial specification | |||

| Parameter | chav tsev | Z-MOS | |

| Hom | Condutivity / Dopant | - | N-hom / Nitrogen |

| Buffer Txheej | Buffer Txheej Thickness | um | 1 |

| Buffer Txheej Thickness kam rau ua | % | ± 20% | |

| Buffer Txheej Concentration | cm-3 | 1.00 Nws + 18 | |

| Buffer Layer Concentration Tolerance | % | ± 20% | |

| 1st Epi Txheej | Epi Txheej Thickness | um | 11.5 |

| Epi Txheej Thickness Uniformity | % | ± 4% | |

| Epi Txheej Thickness Tolerance ((Spec- Max, Min) / Spec) | % | ± 5% | |

| Epi Txheej Concentration | cm-3 | 1E 15 ~ 1E 18 | |

| Epi Txheej Concentration Tolerance | % | 6% | |

| Epi Txheej Concentration Uniformity (σ / txhais) | % | ≤ 5% | |

| Epi Txheej Concentration Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Epitaixal Wafer Shape | Hneev | um | ≤ ± 20 |

| WARP | um | ≤ 30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤ 2 | |

| Cov yam ntxwv dav dav | Kos qhov ntev | mm | ≤30mm |

| Ntug Chips | - | TSIS MUAJ | |

| Defects txhais | ≥97% (Kev ntsuas 2 * 2, Killer defects inludes: Tsis xws luag suav nrog Micropipe / Loj pits, Carrot, Daim duab peb sab | ||

| Hlau paug | atom / cm² | d f ll ib ≤5E10 atoms / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Pob | Packing specifications | pcs / thawv | multi-wafer cassette los yog ib lub thawv wafer |

| 8-nti N-hom epitaxial specification | |||

| Parameter | chav tsev | Z-MOS | |

| Hom | Condutivity / Dopant | - | N-hom / Nitrogen |

| Tsis txheej | Buffer Txheej Thickness | um | 1 |

| Buffer Txheej Thickness kam rau ua | % | ± 20% | |

| Buffer Txheej Concentration | cm-3 | 1.00 Nws + 18 | |

| Buffer Layer Concentration Tolerance | % | ± 20% | |

| 1st Epi Txheej | Epi Txheej Thickness Nruab Nrab | um | 8 ~ 12 |

| Epi Txheej Thickness Uniformity (σ/mean) | % | ≤ 2.0 | |

| Epi Layers Thickness kam rau ua ((Spec -Max, Min) / Spec) | % | ± 6 | |

| Epi Layers Net Nruab Nrab Doping | cm-3 | 8E+15~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/mean) | % | ≤ 5 | |

| Epi Layers Net DopingTolerance((Spec -Max, | % | ± 10.0 | |

| Epitaixal Wafer Shape | Kuv) / S) Warp | um | ≤ 50.0 |

| Hneev | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤ 4.0 (10mm × 10mm) | |

| General Yam ntxwv | Kos | - | Qhov ntev ≤ 1/2 Wafer txoj kab uas hla |

| Ntug Chips | - | ≤2 chips, Txhua lub vojvoog≤1.5mm | |

| Deg hlau Contamination | atom/cm2 | ≤5E10 atoms / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Kev tshuaj xyuas tsis zoo | % | ≥ 96.0 (2X2 Qhov Tsis Zoo suav nrog Micropipe / Qhov Loj, Carrots, triangular defects, downfalls, Linear/IGSF-s, BPD) | |

| Deg hlau Contamination | atom/cm2 | ≤5E10 atoms / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Pob | Packing specifications | - | multi-wafer cassette los yog ib lub thawv wafer |

SiC wafer's Q&A

Q1: Dab tsi yog qhov txiaj ntsig tseem ceeb ntawm kev siv SiC wafers dhau ib txwm siv silicon wafers hauv hluav taws xob hluav taws xob?

A1:

SiC wafers muaj ntau qhov zoo ntawm cov khoom siv silicon (Si) wafers hauv hluav taws xob hluav taws xob, suav nrog:

Ua tau zoo dua: SiC muaj qhov dav bandgap (3.26 eV) piv rau silicon (1.1 eV), tso cai rau cov khoom siv ua haujlwm ntawm qhov hluav taws xob ntau dua, zaus, thiab kub. Qhov no ua rau txo qis hluav taws xob thiab kev ua haujlwm siab dua hauv lub zog hloov hluav taws xob.

High Thermal conductivity: SiC's thermal conductivity yog ntau dua li ntawm silicon, ua kom muaj cua sov zoo dua hauv cov ntawv siv hluav taws xob siab, uas txhim kho kev ntseeg tau thiab lub neej ntev ntawm cov khoom siv hluav taws xob.

Siab dua voltage thiab tam sim no tuav: SiC cov cuab yeej muaj peev xwm tswj tau cov hluav taws xob ntau dua thiab cov qib tam sim no, ua rau lawv tsim nyog rau kev siv hluav taws xob siab xws li tsheb hluav taws xob, hluav taws xob txuas ntxiv mus, thiab cov tsav tsheb muaj zog.

Kev hloov ceev dua: SiC cov cuab yeej muaj peev xwm hloov tau sai dua, uas ua rau txo qis ntawm lub zog poob thiab qhov system loj, ua rau lawv zoo tagnrho rau kev siv ntau zaus.

Q2: Dab tsi yog cov ntawv thov tseem ceeb ntawm SiC wafers hauv kev lag luam tsheb?

A2:

Hauv kev lag luam tsheb, SiC wafers feem ntau yog siv hauv:

Electric Tsheb (EV) Powertrains: SiC-raws li cov khoom xws liinverterthiabzog MOSFETstxhim kho kev ua tau zoo thiab kev ua tau zoo ntawm cov tsheb fais fab fais fab los ntawm kev ua kom muaj kev sib hloov ceev ceev thiab ntau zog ceev. Qhov no ua rau lub roj teeb lub neej ntev dua thiab kev ua haujlwm ntawm lub tsheb zoo dua.

On-Board Chargers: SiC cov cuab yeej pab txhim kho kev ua haujlwm ntawm on-board charging systems los ntawm kev ua kom lub sij hawm them nyiaj sai dua thiab kev tswj xyuas thermal zoo dua, uas yog qhov tseem ceeb rau EVs los txhawb cov chaw them nqi siab.

Battery Management Systems (BMS): SiC thev naus laus zis txhim kho kev ua haujlwm ntawmroj teeb tswj systems, tso cai rau kev tswj hwm qhov hluav taws xob zoo dua, kev tuav lub zog ntau dua, thiab lub roj teeb ntev dua.

DC-DC Converters: SiC wafers yog siv rau hauvDC-DC converterslos hloov high-voltage DC fais fab mus rau qhov tsawg-voltage DC fais fab ntau npaum li cas, uas yog ib qho tseem ceeb nyob rau hauv hluav taws xob tsheb los tswj lub hwj chim ntawm lub roj teeb mus rau ntau yam khoom nyob rau hauv lub tsheb.

SiC qhov kev ua tau zoo tshaj plaws hauv high-voltage, high-temperature, thiab high-efficiency applications ua rau nws tseem ceeb rau kev lag luam tsheb hloov mus rau hluav taws xob.

6inch 4H-N hom SiC wafer tus specification | ||

| Khoom | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

| Qib | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

| Txoj kab uas hla | 149.5mm-150.0 hli | 149.5mm-150.0 hli |

| Poly-hom | 4H | 4H |

| Thickness | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Wafer Orientation | Tawm axis: 4.0 ° mus rau <1120> ± 0.5 ° | Tawm axis: 4.0 ° mus rau <1120> ± 0.5 ° |

| Micropipe ntom ntom | ≤ 0.2 cm² | ≤ 15 cm² |

| Kev tiv thaiv | 0.015 - 0.024 Ω · cm | 0.015 - 0.028 Ω · cm |

| Thawj Txoj Kev Ncaj Ncees | [10-10] ± 50° | [10-10] ± 50° |

| Qhov Loj Loj Loj | 475 hli ± 2.0 hli | 475 hli ± 2.0 hli |

| Ntug Exclusion | 3 hli | 3 hli |

| LTV/TIV/Bow/Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Roughness | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Rau | ≤ 0.2nm | ≤ 0.5nm |

| Ntug Cracks Los ntawm High Intensity Light | Kev sib sau ntev ≤ 20 hli ib qhov ntev ≤ 2 hli | Kev sib sau ntev ≤ 20 hli ib qhov ntev ≤ 2 hli |

| Hex Phaj Los Ntawm Lub Teeb Siab Siab | Qhov ntau thiab tsawg ≤ 0.05% | Cov cheeb tsam ≤ 0.1% |

| Polytype Areas Los Ntawm Lub Teeb Siab Siab | Qhov ntau thiab tsawg ≤ 0.05% | Cov cheeb tsam sib sau ≤ 3% |

| Visual Carbon suav nrog | Qhov ntau thiab tsawg ≤ 0.05% | Qhov ntau thiab tsawg ≤ 5% |

| Silicon Surface Scratches Los ntawm High Intensity Light | Qhov ntev ntev ≤ 1 wafer txoj kab uas hla | |

| Ntug Chips Los ntawm High Intensity Light | Tsis muaj kev tso cai ≥ 0.2 mm dav thiab qhov tob | 7 tso cai, ≤ 1mm txhua |

| Threading Screw Dislocation | <500 cm³ | <500 cm³ |

| Silicon Surface Contamination Los ntawm High Intensity Light | ||

| Ntim | Multi-wafer Cassette lossis Ib Lub Thawv Wafer | Multi-wafer Cassette lossis Ib Lub Thawv Wafer |

8inch 4H-N hom SiC wafer tus specification | ||

| Khoom | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

| Qib | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

| Txoj kab uas hla | 199.5mm-200.0 hli | 199.5mm-200.0 hli |

| Poly-hom | 4H | 4H |

| Thickness | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | 4.0 ° mus rau <110> ± 0.5 ° | 4.0 ° mus rau <110> ± 0.5 ° |

| Micropipe ntom ntom | ≤ 0.2 cm² | ≤ 5 cm² |

| Kev tiv thaiv | 0.015 - 0.025 Ω · cm | 0.015 - 0.028 Ω · cm |

| Noble Orientation | ||

| Ntug Exclusion | 3 hli | 3 hli |

| LTV/TIV/Bow/Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Roughness | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Rau | ≤ 0.2nm | ≤ 0.5nm |

| Ntug Cracks Los ntawm High Intensity Light | Kev sib sau ntev ≤ 20 hli ib qhov ntev ≤ 2 hli | Kev sib sau ntev ≤ 20 hli ib qhov ntev ≤ 2 hli |

| Hex Phaj Los Ntawm Lub Teeb Siab Siab | Qhov ntau thiab tsawg ≤ 0.05% | Cov cheeb tsam ≤ 0.1% |

| Polytype Areas Los Ntawm Lub Teeb Siab Siab | Qhov ntau thiab tsawg ≤ 0.05% | Cov cheeb tsam sib sau ≤ 3% |

| Visual Carbon suav nrog | Qhov ntau thiab tsawg ≤ 0.05% | Qhov ntau thiab tsawg ≤ 5% |

| Silicon Surface Scratches Los ntawm High Intensity Light | Qhov ntev ntev ≤ 1 wafer txoj kab uas hla | |

| Ntug Chips Los ntawm High Intensity Light | Tsis muaj kev tso cai ≥ 0.2 mm dav thiab qhov tob | 7 tso cai, ≤ 1mm txhua |

| Threading Screw Dislocation | <500 cm³ | <500 cm³ |

| Silicon Surface Contamination Los ntawm High Intensity Light | ||

| Ntim | Multi-wafer Cassette lossis Ib Lub Thawv Wafer | Multi-wafer Cassette lossis Ib Lub Thawv Wafer |

6Inch 4H-semi SiC substrate specification | ||

| Khoom | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

| Txoj kab uas hla (mm) | 145mm-150 hli | 145mm-150 hli |

| Poly-hom | 4H | 4H |

| Thickness (hli) | 500 ± 15 | 500 ± 25 |

| Wafer Orientation | axis: ± 0.0001 ° | axis: ± 0.05 ° |

| Micropipe ntom ntom | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Kev tiv thaiv (Ω cm) | ≥10E3 | ≥10E3 |

| Thawj Txoj Kev Ncaj Ncees | (0-10) ° ± 5.0 ° | (10-10) ° ± 5.0 ° |

| Qhov Loj Loj Loj | Ntsig | Ntsig |

| Ntug Exclusion (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Tais / Warp | ≤ 3 µm | ≤ 3 µm |

| Roughness | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Ntug Chips Los ntawm High Intensity Light | ≤ 20 µm | ≤ 60 µm |

| Thaum tshav kub kub daim hlau los ntawm High Intensity Light | Kev sib tw ≤ 0.05% | Kev sib tw ≤ 3% |

| Polytype Areas Los Ntawm Lub Teeb Siab Siab | Kev pom cov pa roj carbon monoxide ≤ 0.05% | Kev sib tw ≤ 3% |

| Silicon Surface Scratches Los ntawm High Intensity Light | ≤ 0.05% | Kev sib tw ≤ 4% |

| Ntug Chips Los Ntawm Lub Teeb Siab Siab (loj) | Tsis Tso Cai> 02 mm Dav thiab qhov tob | Tsis Tso Cai> 02 mm Dav thiab qhov tob |

| Txoj Kev Pab Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Silicon Surface Contamination Los ntawm High Intensity Light | 1 x 10^5 | 1 x 10^5 |

| Ntim | Multi-wafer Cassette lossis Ib Lub Thawv Wafer | Multi-wafer Cassette lossis Ib Lub Thawv Wafer |

4-Inch 4H-Semi Insulating SiC Substrate Specification

| Parameter | Zero MPD Qhuav Qib (Z Qib) | Qib Dummy (D qib) |

|---|---|---|

| Lub cev muaj zog | ||

| Txoj kab uas hla | 99.5mm-100.0 hli | 99.5mm-100.0 hli |

| Poly-hom | 4H | 4H |

| Thickness | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Orientation | Ntawm axis: <600h> 0.5° | Ntawm axis: <000h> 0.5° |

| Cov khoom hluav taws xob | ||

| Micropipe Density (MPD) | ≤1cm⁻² | ≤ 15 cm⁻² |

| Kev tiv thaiv | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Geometric Tolerances | ||

| Thawj Txoj Kev Ncaj Ncees | (0 × 10) ± 5.0 ° | (0 × 10) ± 5.0 ° |

| Qhov Loj Loj Loj | 52.5 hli ± 2.0 hli | 52.5 hli ± 2.0 hli |

| Secondary Flat Length | 18.0 hli ± 2.0 hli | 18.0 hli ± 2.0 hli |

| Secondary Flat Orientation | 90 ° CW ntawm Prime tiaj tus ± 5.0 ° (Si ntsej muag) | 90 ° CW ntawm Prime tiaj tus ± 5.0 ° (Si ntsej muag) |

| Ntug Exclusion | 3 hli | 3 hli |

| LTV / TTV / Hneev / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10μm / ≤15μm / ≤25μm / ≤40μm |

| Nto Zoo | ||

| Nto Roughness (Polish Ra) | ≤ 1 nm | ≤ 1 nm |

| Nto Roughness (CMP Ra) | ≤ 0.2nm | ≤ 0.2nm |

| Ntug Cracks (High-Intensity Light) | Tsis tso cai | Qhov ntev ≥10 hli, ib qho tawg ≤2 hli |

| Hexagonal Phaj Defects | ≤0.05% cheeb tsam sib sau | ≤0.1% cheeb tsam sib sau |

| Polytype Inclusion Areas | Tsis tso cai | ≤1% cheeb tsam sib sau |

| Visual Carbon suav nrog | ≤0.05% cheeb tsam sib sau | ≤1% cheeb tsam sib sau |

| Silicon Surface Scratches | Tsis tso cai | ≤1 wafer txoj kab uas hla cumulative length |

| Ntug Chips | Tsis pub muaj (≥0.2 hli dav / qhov tob) | ≤5 nti (txhua ≤1 hli) |

| Silicon Surface Contamination | Tsis tau teev tseg | Tsis tau teev tseg |

| Ntim | ||

| Ntim | Multi-wafer cassette los yog ib lub thawv wafer | Multi-wafer cassette los yog |

| 6-nti N-hom epit axial specification | |||

| Parameter | chav tsev | Z-MOS | |

| Hom | Condutivity / Dopant | - | N-hom / Nitrogen |

| Buffer Txheej | Buffer Txheej Thickness | um | 1 |

| Buffer Txheej Thickness kam rau ua | % | ± 20% | |

| Buffer Txheej Concentration | cm-3 | 1.00 Nws + 18 | |

| Buffer Layer Concentration Tolerance | % | ± 20% | |

| 1st Epi Txheej | Epi Txheej Thickness | um | 11.5 |

| Epi Txheej Thickness Uniformity | % | ± 4% | |

| Epi Txheej Thickness Tolerance ((Spec- Max, Min) / Spec) | % | ± 5% | |

| Epi Txheej Concentration | cm-3 | 1E 15 ~ 1E 18 | |

| Epi Txheej Concentration Tolerance | % | 6% | |

| Epi Txheej Concentration Uniformity (σ / txhais) | % | ≤ 5% | |

| Epi Txheej Concentration Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Epitaixal Wafer Shape | Hneev | um | ≤ ± 20 |

| WARP | um | ≤ 30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤ 2 | |

| Cov yam ntxwv dav dav | Kos qhov ntev | mm | ≤30mm |

| Ntug Chips | - | TSIS MUAJ | |

| Defects txhais | ≥97% (Kev ntsuas 2 * 2, Killer defects inludes: Tsis xws luag suav nrog Micropipe / Loj pits, Carrot, Daim duab peb sab | ||

| Hlau paug | atom / cm² | d f ll ib ≤5E10 atoms / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Pob | Packing specifications | pcs / thawv | multi-wafer cassette los yog ib lub thawv wafer |

| 8-nti N-hom epitaxial specification | |||

| Parameter | chav tsev | Z-MOS | |

| Hom | Condutivity / Dopant | - | N-hom / Nitrogen |

| Tsis txheej | Buffer Txheej Thickness | um | 1 |

| Buffer Txheej Thickness kam rau ua | % | ± 20% | |

| Buffer Txheej Concentration | cm-3 | 1.00 Nws + 18 | |

| Buffer Layer Concentration Tolerance | % | ± 20% | |

| 1st Epi Txheej | Epi Txheej Thickness Nruab Nrab | um | 8 ~ 12 |

| Epi Txheej Thickness Uniformity (σ/mean) | % | ≤ 2.0 | |

| Epi Layers Thickness kam rau ua ((Spec -Max, Min) / Spec) | % | ± 6 | |

| Epi Layers Net Nruab Nrab Doping | cm-3 | 8E+15~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/mean) | % | ≤ 5 | |

| Epi Layers Net DopingTolerance((Spec -Max, | % | ± 10.0 | |

| Epitaixal Wafer Shape | Kuv) / S) Warp | um | ≤ 50.0 |

| Hneev | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤ 4.0 (10mm × 10mm) | |

| General Yam ntxwv | Kos | - | Qhov ntev ≤ 1/2 Wafer txoj kab uas hla |

| Ntug Chips | - | ≤2 chips, Txhua lub vojvoog≤1.5mm | |

| Deg hlau Contamination | atom/cm2 | ≤5E10 atoms / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Kev tshuaj xyuas tsis zoo | % | ≥ 96.0 (2X2 Qhov Tsis Zoo suav nrog Micropipe / Qhov Loj, Carrots, triangular defects, downfalls, Linear/IGSF-s, BPD) | |

| Deg hlau Contamination | atom/cm2 | ≤5E10 atoms / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Pob | Packing specifications | - | multi-wafer cassette los yog ib lub thawv wafer |

Q1: Dab tsi yog qhov txiaj ntsig tseem ceeb ntawm kev siv SiC wafers dhau ib txwm siv silicon wafers hauv hluav taws xob hluav taws xob?

A1:

SiC wafers muaj ntau qhov zoo ntawm cov khoom siv silicon (Si) wafers hauv hluav taws xob hluav taws xob, suav nrog:

Ua tau zoo dua: SiC muaj qhov dav bandgap (3.26 eV) piv rau silicon (1.1 eV), tso cai rau cov khoom siv ua haujlwm ntawm qhov hluav taws xob ntau dua, zaus, thiab kub. Qhov no ua rau txo qis hluav taws xob thiab kev ua haujlwm siab dua hauv lub zog hloov hluav taws xob.

High Thermal conductivity: SiC's thermal conductivity yog ntau dua li ntawm silicon, ua kom muaj cua sov zoo dua hauv cov ntawv siv hluav taws xob siab, uas txhim kho kev ntseeg tau thiab lub neej ntev ntawm cov khoom siv hluav taws xob.

Siab dua voltage thiab tam sim no tuav: SiC cov cuab yeej muaj peev xwm tswj tau cov hluav taws xob ntau dua thiab cov qib tam sim no, ua rau lawv tsim nyog rau kev siv hluav taws xob siab xws li tsheb hluav taws xob, hluav taws xob txuas ntxiv mus, thiab cov tsav tsheb muaj zog.

Kev hloov ceev dua: SiC cov cuab yeej muaj peev xwm hloov tau sai dua, uas ua rau txo qis ntawm lub zog poob thiab qhov system loj, ua rau lawv zoo tagnrho rau kev siv ntau zaus.

Q2: Dab tsi yog cov ntawv thov tseem ceeb ntawm SiC wafers hauv kev lag luam tsheb?

A2:

Hauv kev lag luam tsheb, SiC wafers feem ntau yog siv hauv:

Electric Tsheb (EV) Powertrains: SiC-raws li cov khoom xws liinverterthiabzog MOSFETstxhim kho kev ua tau zoo thiab kev ua tau zoo ntawm cov tsheb fais fab fais fab los ntawm kev ua kom muaj kev sib hloov ceev ceev thiab ntau zog ceev. Qhov no ua rau lub roj teeb lub neej ntev dua thiab kev ua haujlwm ntawm lub tsheb zoo dua.

On-Board Chargers: SiC cov cuab yeej pab txhim kho kev ua haujlwm ntawm on-board charging systems los ntawm kev ua kom lub sij hawm them nyiaj sai dua thiab kev tswj xyuas thermal zoo dua, uas yog qhov tseem ceeb rau EVs los txhawb cov chaw them nqi siab.

Battery Management Systems (BMS): SiC thev naus laus zis txhim kho kev ua haujlwm ntawmroj teeb tswj systems, tso cai rau kev tswj hwm qhov hluav taws xob zoo dua, kev tuav lub zog ntau dua, thiab lub roj teeb ntev dua.

DC-DC Converters: SiC wafers yog siv rau hauvDC-DC converterslos hloov high-voltage DC fais fab mus rau qhov tsawg-voltage DC fais fab ntau npaum li cas, uas yog ib qho tseem ceeb nyob rau hauv hluav taws xob tsheb los tswj lub hwj chim ntawm lub roj teeb mus rau ntau yam khoom nyob rau hauv lub tsheb.

SiC qhov kev ua tau zoo tshaj plaws hauv high-voltage, high-temperature, thiab high-efficiency applications ua rau nws tseem ceeb rau kev lag luam tsheb hloov mus rau hluav taws xob.