SiO₂ Quartz Wafer Quartz Wafers SiO₂ MEMS Kub 2 "3" 4 "6" 8 "12"

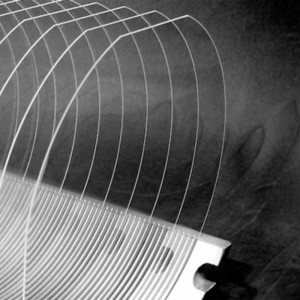

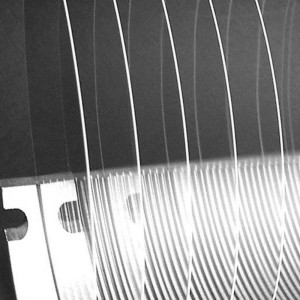

Daim duab qhia ntxaws

Taw qhia

Quartz wafers ua lub luag haujlwm tseem ceeb hauv kev nce qib hauv electronics, semiconductor, thiab optics industries. Pom nyob rau hauv smartphones coj koj GPS, embedded nyob rau hauv high-frequency base chaw nres tsheb powering 5G tes hauj lwm, thiab kev koom ua ke rau hauv cov cuab yeej tsim tom ntej-gen microchips, quartz wafers yog qhov tseem ceeb. Cov high-purity substrates pab kev nrhav nyob rau hauv txhua yam los ntawm quantum xam mus rau advanced photonics. Txawm hais tias tau muab los ntawm ib qho ntawm lub ntiaj teb cov zaub mov ntau tshaj plaws, quartz wafers yog tsim los rau cov qauv txawv txawv ntawm qhov tseeb thiab kev ua haujlwm.

Dab tsi yog Quartz Wafers

Quartz wafers yog nyias, ncig discs tsim los ntawm ultra-ntshiab hluavtaws quartz siv lead ua. Muaj nyob rau hauv tus qauv diameters li ntawm 2 mus rau 12 ntiv tes, quartz wafers feem ntau nyob rau hauv thickness ntawm 0.5 hli mus rau 6 hli. Tsis zoo li ntuj quartz, uas tsim cov prismatic crystals tsis tu ncua, hluavtaws quartz yog loj hlob nyob rau hauv nruj tswj cov chaw kuaj mob, tsim cov qauv siv lead ua zoo li qub.

Lub hauv paus crystallinity ntawm quartz wafers muab cov tshuaj tsis sib haum xeeb, qhov pom kev pom tseeb, thiab kev ruaj ntseg nyob rau hauv qhov kub thiab txias thiab kev ntxhov siab. Cov yam ntxwv no ua rau quartz wafers yog lub hauv paus tseem ceeb rau cov cuab yeej siv tau zoo siv hauv cov ntaub ntawv xa mus, kev paub, kev suav, thiab laser-raws li thev naus laus zis.

Quartz Wafer Specifications

| Quartz Hom | 4 | 6 | 8 | 12 |

|---|---|---|---|---|

| Loj | ||||

| Txoj kab uas hla (inch) | 4 | 6 | 8 | 12 |

| Thickness (hli) | 0.05—2 | 0.25–5.0 Nws | 0.3–5 | 0.4–5 |

| Txoj kab uas hla (inch) | ± 0.1 | ± 0.1 | ± 0.1 | ± 0.1 |

| Thickness kam rau ua (mm) | Customizable | Customizable | Customizable | Customizable |

| Optical Properties | ||||

| Refractive Index @ 365 nm | 1.474698 ib | 1.474698 ib | 1.474698 ib | 1.474698 ib |

| Refractive Index @546.1nm | 1.460 243 ib | 1.460 243 ib | 1.460 243 ib | 1.460 243 ib |

| Refractive Index @ 1014 nm | 1.450423 | 1.450423 | 1.450423 | 1.450423 |

| Sab hauv Transmittance (1250-1650 nm) | > 99.9% | > 99.9% | > 99.9% | > 99.9% |

| Transmittance tag nrho (1250-1650 nm) | > 92% | > 92% | > 92% | > 92% |

| Machining Zoo | ||||

| TTV (Tag nrho Thickness Variation, µm) | <3 | <3 | <3 | <3 |

| Flatness (µm) | ≤ 15 | ≤ 15 | ≤ 15 | ≤ 15 |

| Nto Roughness (nm) | ≤1 | ≤1 | ≤1 | ≤1 |

| Hnyav (µm) | <5 | <5 | <5 | <5 |

| Lub cev muaj zog | ||||

| Qhov ceev (g / cm³) | 2.20 | 2.20 | 2.20 | 2.20 |

| Young's Modulus (GPa) | 74.20 Nws | 74.20 Nws | 74.20 Nws | 74.20 Nws |

| Mohs Hardness | 6–7 | 6–7 | 6–7 | 6–7 |

| Shear Modulus (GPa) | 31.22 Nws | 31.22 Nws | 31.22 Nws | 31.22 Nws |

| Poisson tus ratio | 0.17 ib | 0.17 ib | 0.17 ib | 0.17 ib |

| Compressive zog (GPa) | 1.13 | 1.13 | 1.13 | 1.13 |

| Tensile zog (MPa) | 49 | 49 | 49 | 49 |

| Dielectric qhov tsis tu ncua (1 MHz) | 3.75 ib | 3.75 ib | 3.75 ib | 3.75 ib |

| Thermal Properties | ||||

| Strain Point (10¹⁴.⁵ Pa·s) | 1000 ° C | 1000 ° C | 1000 ° C | 1000 ° C |

| Annealing Point (10¹³ Pa·s) | 1160 ° C | 1160 ° C | 1160 ° C | 1160 ° C |

| Softening Point (10⁷.⁶ Pa·s) | 1620 ° C | 1620 ° C | 1620 ° C | 1620 ° C |

Kev siv ntawm Quartz Wafers

Quartz wafers yog kev cai-engineered kom tau raws li xav tau daim ntawv thov thoob plaws kev lag luam suav nrog:

Electronics thiab RF Devices

- Quartz wafers yog cov tseem ceeb rau quartz siv lead ua resonators thiab oscillators uas muab lub moos teeb liab rau smartphones, GPS units, computers, thiab wireless sib txuas lus.

- Lawv cov thermal expansion qis thiab siab Q-factor ua quartz wafers zoo meej rau lub sijhawm ruaj khov thiab RF lim.

Optoelectronics thiab Imaging

- Quartz wafers muab UV thiab IR transmittance zoo tshaj plaws, ua rau lawv zoo tagnrho rau cov lo ntsiab muag kho qhov muag, beam splitters, laser windows, thiab detectors.

- Lawv tiv taus hluav taws xob ua rau siv tau rau hauv lub zog siab physics thiab qhov chaw ntsuas.

Semiconductor thiab MEMS

- Quartz wafers ua cov substrates rau high-frequency semiconductor circuits, tshwj xeeb tshaj yog nyob rau hauv GaN thiab RF daim ntaub ntawv.

- Hauv MEMS (Micro-Electro-Mechanical Systems), quartz wafers hloov cov khoom siv hluav taws xob rau hauv cov hluav taws xob los ntawm cov nyhuv piezoelectric, ua kom cov sensors zoo li gyroscopes thiab accelerometers.

Advanced Manufacturing & Labs

- High-purity quartz wafers yog dav siv nyob rau hauv tshuaj, biomedical, thiab photonic labs rau optical hlwb, UV cuvettes, thiab high-temperature tuav.

- Lawv compatibility nrog huab ib puag ncig ua rau lawv haum rau plasma chambers thiab deposition cov cuab yeej.

Yuav Ua Li Cas Quartz Wafers Ua

Muaj ob txoj hauv kev tsim khoom rau quartz wafers:

Fused Quartz Wafers

Fused quartz wafers yog tsim los ntawm melting ntuj quartz granules rau hauv ib lub iav amorphous, ces txiav thiab polishing cov khoom thaiv rau hauv nyias wafers. Cov quartz wafers muaj:

- Exceptional UV pob tshab

- Kev khiav hauj lwm dav dav (> 1100 ° C)

- Zoo heev thermal shock kuj

Lawv yog cov zoo tagnrho rau cov khoom siv lithography, qhov cub kub kub, thiab cov qhov rais kho qhov muag tab sis tsis haum rau kev siv piezoelectric vim tsis muaj crystalline kev txiav txim.

Cultured Quartz Wafers

Cultured quartz wafers yog zus synthetically los tsim cov muaju tsis xws luag nrog meej lattice orientation. Cov wafers no yog tsim los rau cov ntawv thov uas xav tau:

- Lub kaum ntse ntse txiav (X-, Y-, Z-, AT-txiav, thiab lwm yam)

- High-frequency oscillators thiab SAW lim

- Optical polarizers thiab advanced MEMS li

Cov txheej txheem ntau lawm suav nrog kev loj hlob ntawm noob hauv autoclaves, ua raws li kev txiav, kev taw qhia, annealing, thiab polishing.

Ua Quartz Wafer Suppliers

Cov neeg muag khoom thoob ntiaj teb tshwj xeeb hauv kev ua haujlwm siab quartz wafers suav nrog:

- Heraus(Lub teb chaws Yelemees) - fused thiab hluavtaws quartz

- Quartz xim(Nyiv) - high-purity wafer daws

- WaferPro(Tebchaws USA) - dav quartz wafers thiab substrates

- Korth Kristalle(Lub teb chaws Yelemees) - hluavtaws siv lead ua wafers

Lub luag haujlwm Evolving ntawm Quartz Wafers

Quartz wafers txuas ntxiv hloov zuj zus raws li cov khoom tseem ceeb hauv kev tsim kho vaj tse:

- Miniaturization- Quartz wafers tau tsim nrog nruj dua rau kev sib koom ua ke ntawm cov cuab yeej sib txuas.

- Ntau zaus Electronics- Tshiab quartz wafer tsim yog thawb rau hauv mmWave thiab THz domains rau 6G thiab radar.

- Next-Gen Sensing- Los ntawm kev siv tsheb mus rau kev lag luam IoT, quartz-based sensors tau dhau los ua qhov tseem ceeb.

Cov lus nug nquag nug txog quartz wafers

1. Dab tsi yog quartz wafer?

Lub quartz wafer yog nyias, tiaj tus disc ua los ntawm crystalline silicon dioxide (SiO₂), feem ntau tsim nyob rau hauv cov qauv semiconductor ntau thiab tsawg (xws li, 2", 3", 4", 6", 8", 12 "). Paub txog nws cov purity siab, thermal stability, thiab optical transparency, quartz wafer yog siv los ua ib tug substrate los yog cab kuj nyob rau hauv ntau yam high-precision daim ntaub ntawv xws li semiconductor fabrication, MEMS li, optical systems, thiab lub tshuab nqus tsev vacuum.

2. Dab tsi yog qhov txawv ntawm quartz thiab silica gel?

Quartz yog crystalline khoom ntawm silicon dioxide (SiO₂), thaum silica gel yog amorphous thiab ntxeem tau ntawm SiO₂, feem ntau yog siv los ua desiccant kom nqus dej noo.

- Quartz yog ib qho nyuaj, pob tshab, thiab siv hauv kev siv hluav taws xob, kho qhov muag, thiab kev lag luam.

- Silica gel zoo li cov hlaws me me los yog granules thiab feem ntau yog siv los tswj cov av noo hauv ntim khoom, khoom siv hluav taws xob, thiab khaws cia.

3. Dab tsi yog quartz siv lead ua?

Quartz muaju yog dav siv nyob rau hauv electronics thiab optics vim lawv piezoelectric zog (lawv tsim ib tug nqi hluav taws xob nyob rau hauv txhua yam kev nyuaj siab). Cov ntawv thov uas muaj xws li:

- Oscillators thiab zaus tswj(piv txwv li, quartz watches, moos, microcontrollers)

- Optical Cheebtsam(xws li lo ntsiab muag, waveplates, windows)

- Resonators thiab limhauv RF thiab cov khoom siv sib txuas lus

- Sensorsrau siab, acceleration, los yog quab yuam

- Kev lag luam semiconductorraws li substrates lossis txheej txheem windows

4. Vim li cas quartz siv hauv microchips?

Quartz yog siv rau hauv microchip daim ntawv thov vim nws muaj:

- Thermal stabilityThaum lub sij hawm kub txheej txheem xws li diffusion thiab annealing

- Hluav taws xob rwb thaiv tsevvim nws cov khoom dielectric

- Tshuaj tiv thaivrau cov kua qaub thiab cov kuab tshuaj siv hauv semiconductor fabrication

- Dimensional precisionthiab tsis tshua muaj thermal expansion rau txhim khu kev qha lithography sib dhos

- Thaum quartz nws tus kheej tsis yog siv los ua cov khoom siv semiconductor (xws li silicon), nws plays lub luag haujlwm tseem ceeb hauv kev tsim ib puag ncig-tshwj xeeb tshaj yog nyob rau hauv furnaces, chambers, thiab photomask substrates.

Txog Peb

XKH tshwj xeeb hauv kev tsim cov thev naus laus zis, tsim khoom, thiab muag cov iav tshwj xeeb kho qhov muag thiab cov ntaub ntawv siv lead ua tshiab. Peb cov khoom siv kho qhov muag khoom siv hluav taws xob, khoom siv hluav taws xob, thiab tub rog. Peb muab Sapphire optical Cheebtsam, xov tooj ntawm tes lens npog, Ceramics, LT, Silicon Carbide SIC, Quartz, thiab semiconductor siv lead ua wafers. Nrog cov kws tshaj lij thiab cov cuab yeej siv niaj hnub, peb ua tau zoo hauv kev ua cov khoom lag luam uas tsis yog tus qauv, aiming los ua ib qho khoom siv optoelectronic high-tech enterprise.