Wafer Thinning Equipment rau 4 Nti-12 Nti Sapphire / SiC / Si Wafers

Txoj Cai Ua Haujlwm

Cov txheej txheem wafer thinning ua haujlwm los ntawm peb theem:

Rough Sib Tsoo: Lub pob zeb diamond log (grit loj 200-500 μm) tshem tawm 50-150 μm ntawm cov khoom ntawm 3000-5000 rpm kom txo cov tuab sai.

Kev Sib Tsoo Zoo: Lub log zoo dua (grit loj 1-50 μm) txo cov tuab mus rau 20-50 μm ntawm <1 μm / s kom txo qis kev puas tsuaj hauv av.

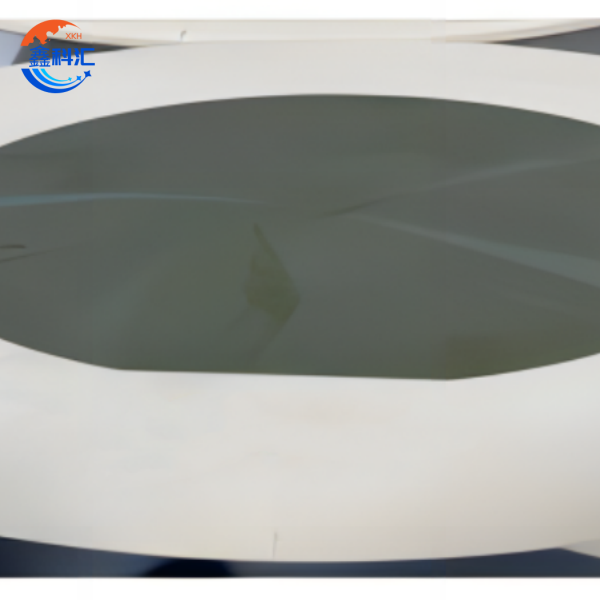

Polishing (CMP): Cov tshuaj-mechanical slurry tshem tawm cov kev puas tsuaj, ua tiav Ra <0.1 nm.

Cov khoom siv sib xws

Silicon (Si): Txheem rau CMOS wafers, thinned mus rau 25 μm rau 3D stacking.

Silicon Carbide (SiC): Yuav tsum tau tshwj xeeb pob zeb diamond log (80% pob zeb diamond concentration) rau thermal stability.

Sapphire (Al₂O₃): Thinned rau 50 μm rau UV LED daim ntaub ntawv.

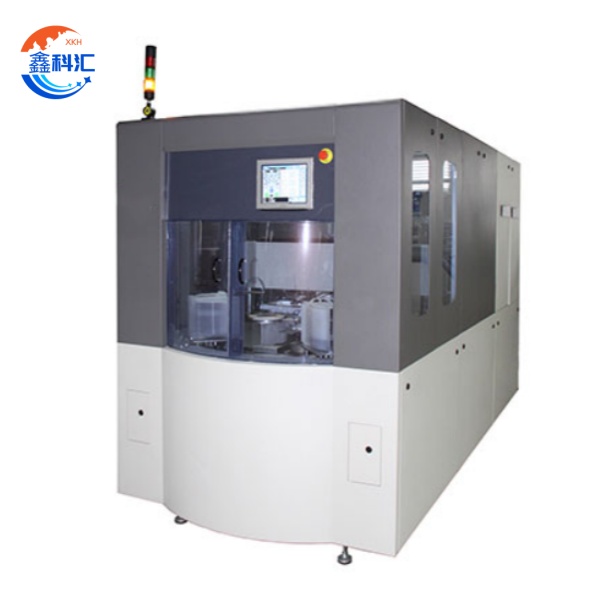

Core System Cheebtsam

1. Sib tsoo System

Dual-Axis Grinder: Muab cov ntxhib / zoo sib tsoo hauv ib lub platform, txo lub sijhawm voj voog los ntawm 40%.

Aerostatic Spindle: 0-6000 rpm ceev ntau yam nrog <0.5 μm radial runout.

2. Wafer Handling System

Nqus Chuck:> 50 N tuav quab yuam nrog ± 0.1 μm qhov chaw raug.

Robotic Arm: Thauj 4-12-nti wafers ntawm 100 mm / s.

3. Tswj System

Laser Interferometry: Real-time thickness xyuas (kev daws teeb meem 0.01 μm).

AI-Driven Feedforward: kwv yees lub log hnav thiab kho qhov tsis zoo.

4. Txias & Ntxuav

Ultrasonic Tu: Tshem tawm cov khoom> 0.5 μm nrog 99.9% efficiency.

Deionized Dej: Txias wafer mus rau <5 ° C saum ambient.

Core Zoo

1. Ultra-High Precision: TTV (Tag nrho Thickness Variation) <0.5 μm, WTW (Within-Wafer Thickness Variation) <1 μm.

2. Multi-Process Integration: Muab kev sib tsoo, CMP, thiab plasma etching hauv ib lub tshuab.

3. Khoom siv Compatibility:

Silicon: Thickness txo los ntawm 775 μm mus rau 25 μm.

SiC: Ua tiav <2 μm TTV rau RF daim ntawv thov.

Doped Wafers: Phosphorus-doped InP wafers nrog <5% resistivity drift.

4. Smart Automation: MES kev koom ua ke txo tib neeg kev ua yuam kev los ntawm 70%.

5. Zog Efficiency: 30% qis zog noj ntawm regenerative braking.

Cov ntawv thov tseem ceeb

1. Advanced Ntim

• 3D ICs: Wafer thinning enables ntsug stacking logic / nco chips (xws li, HBM stacks), ua tiav 10 × siab bandwidth thiab 50% txo hwj chim noj piv rau 2.5D daws. Cov cuab yeej txhawb nqa kev sib koom ua ke thiab TSV (Through-Silicon Via) kev koom ua ke, tseem ceeb rau AI / ML processors xav tau <10 μm interconnect suab. Piv txwv li, 12-nti wafers thinned rau 25 μm cia stacking 8+ khaubncaws sab nraud povtseg thaum tuav <1.5% warpage, tseem ceeb rau tsheb LiDAR systems.

• Ntxuam-Tawm Ntim: Los ntawm kev txo cov wafer thickness rau 30 μm, interconnect ntev yog luv luv los ntawm 50%, txo cov teeb liab ncua sij hawm (<0.2 ps/mm) thiab ua kom 0.4 hli ultra-thin chiplets rau mobile SoCs. Cov txheej txheem leverages kev nyuaj siab-compensated sib tsoo algorithms los tiv thaiv warpage (> 50 μm TTV tswj), ua kom ntseeg tau nyob rau hauv high-frequency RF daim ntaub ntawv.

2. Fais fab Electronics

• IGBT Modules: Thinning mus rau 50 μm txo cov thermal tsis kam mus rau <0.5 ° C / W, ua kom 1200V SiC MOSFETs ua haujlwm ntawm 200 ° C hlws ris kub. Peb cov cuab yeej siv ntau theem sib tsoo ( ntxhib: 46 μm grit → nplua: 4 μm grit) txhawm rau tshem tawm cov kev puas tsuaj hauv av, ua tiav> 10,000 lub voj voog ntawm thermal cycling kev ntseeg tau. Qhov no yog qhov tseem ceeb rau EV inverters, qhov twg 10 μm-tuab SiC wafers txhim kho kev hloov ceev los ntawm 30%.

• GaN-on-SiC Fais Fab Devices: Wafer thinning mus rau 80 μm txhim khu kev txav hluav taws xob (μ> 2000 cm² / V·s) rau 650V GaN HEMTs, txo cov conduction poob los ntawm 18%. Cov txheej txheem siv laser-pab dicing kom tiv thaiv kev tawg thaum lub sij hawm thinning, ua tiav <5 μm ntug chipping rau RF fais fab amplifiers.

3. Optoelectronics

• GaN-on-SiC LEDs: 50 μm sapphire substrates txhim kho lub teeb extraction efficiency (LEE) mus rau 85% (vs. 65% rau 150 μm wafers) los ntawm kev txo cov photon ntxiab. Peb cov khoom siv ultra-low TTV tswj (<0.3 μm) ua kom zoo ib yam LED emission hla 12-nti wafers, tseem ceeb rau Micro-LED cov lus xav tau <100nm wavelength uniformity.

• Silicon Photonics: 25μm-thick silicon wafers pab kom 3 dB/cm qis propagation poob hauv waveguides, qhov tseem ceeb rau 1.6 Tbps optical transceivers. Cov txheej txheem sib xyaw ua ke CMP smoothing kom txo qhov roughness ntawm Ra <0.1 nm, txhim kho kev sib txuas ua haujlwm los ntawm 40%.

4. MEMS Sensors

• Accelerometers: 25 μm silicon wafers ua tiav SNR> 85 dB (vs. 75 dB rau 50 μm wafers) los ntawm kev ua pov thawj-mass rhiab heev. Peb lub tshuab sib tsoo dual-axis them nyiaj rau kev ntxhov siab gradients, ua kom <0.5% rhiab heev drift tshaj -40 ° C txog 125 ° C. Cov ntawv thov suav nrog kev tshawb nrhiav tsheb sib tsoo thiab AR / VR kev taug qab.

• Siab Sensors: Thinning mus rau 40 μm enables 0–300 bar ntsuas ntau yam nrog <0.1% FS hysteresis. Siv cov kev sib txuas ib ntus (cov nqa iav), cov txheej txheem zam wafer tawg thaum lub sij hawm backside etching, ua tiav <1 μm overpressure kam rau ua rau industrial IoT sensors.

• Technical Synergy: Peb cov khoom siv wafer thinning sib koom ua ke sib tsoo tshuab, CMP, thiab plasma etching los daws cov teeb meem sib txawv (Si, SiC, Sapphire). Piv txwv li, GaN-on-SiC yuav tsum tau hybrid sib tsoo (pob zeb diamond log + plasma) kom sib npaug hardness thiab thermal expansion, thaum MEMS sensors xav tau sub-5 nm nto roughness ntawm CMP polishing.

• Kev cuam tshuam kev lag luam: Los ntawm kev ua kom nyias nyias, kev ua tau zoo dua wafers, cov thev naus laus zis no ua rau muaj kev hloov kho tshiab hauv AI chips, 5G mmWave modules, thiab cov khoom siv hluav taws xob hloov tau yooj yim, nrog rau TTV kam rau ua <0.1 μm rau cov lus foldable thiab <0.5 μm rau tsheb LiDAR sensors.

XKH's Services

1. Kev daws teeb meem

Scalable Configurations: 4-12-nti chamber tsim nrog automated loading / unloading.

Doping Support: Cov zaub mov txawv rau Er / Yb-doped crystals thiab InP / GaAs wafers.

2. End-to-End Support

Kev Txhim Kho Txheej Txheem: Kev sim dawb khiav nrog kev ua kom zoo.

Kev cob qhia thoob ntiaj teb: Kev cob qhia kev cob qhia txhua xyoo ntawm kev saib xyuas thiab kev daws teeb meem.

3. Multi-Material Processing

SiC: Wafer thinning mus rau 100 μm nrog Ra <0.1 nm.

Sapphire: 50μm thickness rau UV laser qhov rais (transmittance> 92% @ 200 nm).

4. Kev Pabcuam Nqis Ntxiv

Consumable Supply: Pob zeb diamond log (2000+ wafers / lub neej) thiab CMP slurries.

Xaus

Cov khoom siv wafer thinning no muab kev lag luam-ua precision, ntau yam khoom siv ntau yam, thiab kev siv lub tshuab ntse ntse, ua rau nws tseem ceeb rau kev sib koom ua ke 3D thiab hluav taws xob hluav taws xob. XKH cov kev pabcuam dav dav - los ntawm kev hloov kho mus rau tom qab ua tiav - xyuas kom cov neeg siv khoom tau txais txiaj ntsig zoo thiab kev ua tau zoo hauv kev tsim khoom semiconductor.